Resource Navigation

Building a Visual Workplace

03

February,

2023

3 MINUTE READ

Webinar | Build a Visual Workplace

Building a Visual Workplace

Reduce all forms of waste with visual communication

- Apply six core questions to identify information gaps and problems

- Develop visual standards to improve the workflow

- Create visuals for your needs

18:30 mins

18:30 mins Presented By

Brian McFadden

Technical Writer

Compliance Specialist

Transcript

Webinar Preview

Contents of the Building a Visual Workplace Webinar:

- What is "Visual Workplace"?

- The Six Core Questions

- Using the Core Questions

- Types of Visual Signals

- Safety Signs

- Identification Labels and "Addresses"

- Borders, Zones, and Shadows

- Tags, Cards, and Indicators

- Instruction Labels

- Three Steps for Creating Visual Signals

- Build a Plan

- Designing and Placing Visuals

- Creating Your Own Visuals

Excerpt from the Building a Visual Workplace Webinar transcript:

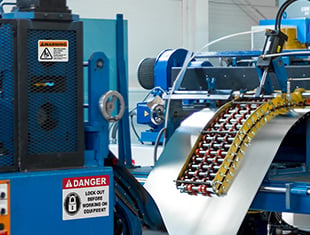

Safety Signs

Safety signs - or, as OSHA calls them, "Accident Prevention Signs" - are some of the most important visual signals in any workplace. These signs provide a warning about a hazard, or instructions on how to stay safe. OSHA has some basic requirements for these signs in 29 CFR 1910.145. Industry experts have also put together an accepted standard that's updated more frequently, and offers a more comprehensive set of recommendations: ANSI/NEMA Z535.

The Z535 standard uses a series of boldly-colored headers and memorable signal words, typically at the top of a sign, to help workers quickly recognize what kind of message they're seeing:

- Yellow, with the word "Caution," for minor or moderate hazards,

- Orange, with the word "Warning," for more serious hazards,

- and Red, with the word "Danger," for the most severe hazards.

These signs use the Safety Alert Symbol (the exclamation point in a triangle) to indicate that their message concerns a risk of personal injury. For safety messages that don't directly relate to personal injury, there are two additional headers and signal words:

- Green, with the word "Safety," for emergency equipment locations and safety procedures,

- and Blue, with the word "Notice," for non-emergency information and instructions.

When used correctly, this system of signs will meet OSHA's requirements for safety signage, and will help protect your workers and your facility from harm.

Identification Labels and "Addresses"

Basic identification labels are probably the most common forms of visual communication; they include bin labels, rack labels, door signs, wire wraps, and pipe markers. Essentially, identification labels give a name to the thing they're posted on.

In many cases, these labels are used to answer the "Where?" Core Question, such as "where are the 3/8-inch bolts?" or "where is the janitorial closet?" In that way, they act very much like the address numbers on a building - helping to orient people, and keeping things from being lost. That's why Dr. Galsworth refers to these kinds of labels as "Addresses": they identify a specific location.

Borders, Zones, and Shadows

Not all visuals need to include text. The lines that mark lanes on a road don't rely on printed words - instead, the color, placement, and pattern provide the information that's needed. In a workplace, the same ideas apply to borders, zones, and shadows.

These related kinds of markings use colored lines, areas, or shapes to identify spaces. You might see a line on the floor to divide pedestrian traffic from forklifts, a striped area around equipment to show the space that needs to be kept clear, or a cutout of a tool on a pegboard showing where that tool belongs.

Because these markings often go on a floor, where traffic and daily wear can quickly destroy them, it's important to use materials that are durable enough to withstand that punishment. The PathFinder line of floor marking, wayfinding, and safety tapes from DuraLabel offer tough and reliable options for a variety of circumstances.

Tags, Cards, and Indicators

Sometimes a visual signal is needed in one place only temporarily, and then it's needed elsewhere. In these cases, tags, cards, and movable indicators are more effective than permanent labels, signs, or tapes.

For example, lockout/tagout systems use highly visible tags to identify equipment that's been shut down for maintenance; when the work is done and the machinery can be started up again, the tag is removed. These hanging tags are typically made with a tear-resistant, non-adhesive tag stock.

Tags or cards can also be used for checkout processes to help keep track of tools, equipment, or employees. For example, if Joe needs to use the 10-millimeter wrench, he can hang his tool tag on the pegboard in its place - and if someone else needs the wrench later on, they'll know who has it. For these kinds of markers, a rigid plastic backing can make the tag more useful.

This approach also works well for multi-part visuals. For example, a mail schedule might list the times for shipping pickups and deliveries, with a magnetic arrow that can be moved over the course of the day to show the time of the next pickup. The basic sign provides a lot of information, but the movable indicator highlights the most important detail - and can be easily updated as each pickup is made.

Instruction Labels

Finally, instruction labels go beyond basic identification or marking to provide detailed procedures in a step-by-step sequence. Whether they describe the cleanup steps for spill response or the shutdown procedure for large equipment, they offer a sense of certainty. Any worker who needs to follow those instructions will be able to refer to them easily, and know that they aren't missing any steps.

These kinds of labels or signs can get pretty large, depending on the amount of information that needs to be included. The DuraLabel Kodiak offers a convenient and reliable way to create these large signs, and allows you to use multiple colors to take advantage of color-coding systems or improve sign visibility.

To learn the about common types of visual signals, and practical guidance on maximizing the value of visuals in your facility, watch the full webinar on demand now!

RELATED RESOURCES

Signage for Safety & OSHA Compliance

Webinar | Signage for Safety & OSHA Compliance Signage for Safety & OSHA Compliance Improve your ...

Watch Now

Effective Wayfinding In Your Facility

Webinar | Effective Wayfinding Effective Wayfinding In Your Facility Help people safely find their way ...

Watch Now

Productive Floor Marking

Webinar | Productive Floor Marking Productive Floor Marking Maximize efficiency with productive floor marking ...

Watch Now.png)