Benefits of using a Product Configurator

Industries using sheet metal as raw material are transforming. Fabricators are becoming more inclined to cater to the customer specific designs to be more profitable and have a recurring customer base.

But in the process of offering such bespoke designs and practicing ETO and CTO manufacturing methods, the workflows become iterative.

Both, ETO and CTO based manufacturing have significant customer involvement during design finalization.

In ETO, customer specifications are required; while in the latter, customers are offered a variety of choices to configure the finished product.

As a result, each new purchased material results in a unique part number, BOMs, routing, etc.

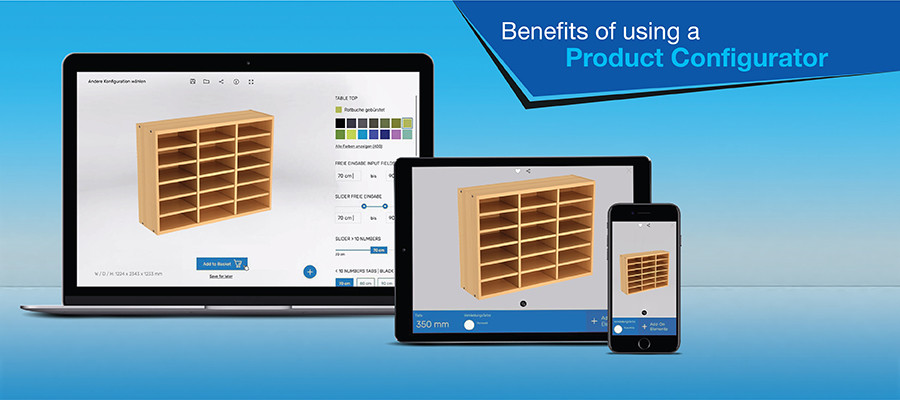

Establishing a common platform for design communication: Product Configurator

All these factors contribute to longer engineering lead times that create difficulties for manufacturers; as a result design handoffs between the two become fragmented.

In order to establish harmony, there should be a common platform, such as 3D product configurators, for all teams: customers/sales representatives, designers, and manufacturers.

Features of product configurators such as guided-selling and need-based selling, DIY and rule-based configurations, and much more help manufacturers streamline their workflows in case of mass customization.

Let’s take a look at the impacts of product configurator from sales to manufacturing.

Product configurators thus add value across the value chain, right from the first sales inquiry to the dispatch of the final product.

They simplify design and engineering configuration, generate an immediate and accurate quote and set the right and competitive pricing.

Today, when the entire manufacturing industry is embracing mass customization, ETO and CTO based manufacturers must adopt product configurators to drive business growth and facilitate their customers better.

Article Originally published at: How Product Configurators can Resolve Challenges in Mass Customization

About Author: Usha B. Trivedi is a mechanical design engineer at Hi-Tech Engineering services - a company invested in industrial CAD drafting, modeling, and design automation. Ms. Trivedi writes about solution finding approach in CAD and design automation challenges backed by her years of exploration in industrial designing in furniture, millwork, and metal fabrication designs.