Yields in focus 10 TONNE PROJECT GROWS

Goin greeng

SUST AIN I N AC A B I L I T Y TION

VOLUME 18 ISSUE 3 AUGUST 2022 | DRIED GRAPE INDUSTRY AWARDS 2022 EXPORT SNAPSHOT | FRUIT FLY VIGILANCE KEY FOR SPRING

Ready for the picking season?

Dual weight ranging compact scale Robust and reliable, the light-weight Japanese designed IPC series of compact scales can withstand rough conditions to produce accurate weight results, and runs on only two D-size batteries. Dual range weighing improves weighing data, and has a large LCD screen for easy reading and a helpful battery ‘save’ function. The IPC comes in 3kg, 6kg, 15kg and 30kg weighing models, with a water proof model also available. Trade approved and certified National Measurement Institute (NMI) approved for trade within Australia, C-Tick Compliant and Country of Origin Labeling (CoOL) compliant.

Ishida Commercial Products (ICP) | Scales + Weighing Systems icpsales@heatandcontrol.com.au | Tel: +61 7 3877 6333 heatandcontrol.com

EXCLUSIVE SUPPLIER OF ISHIDA SYSTEMS IN AUSTRALIA

Contents 4

Cover story 10 Tonne Project grows

30 Biosecurity Levy to protect dried grape industries

8

News Going green

31 Biosecurity Spot the difference

10 DFA chair, CEO & industry updates

32 Biosecurity Action for a positive fruit fly season

12 ATGA CEO & industry updates

34 Processing & marketing APDF

14 Dried grape news

35 Processing & marketing Sunbeam Foods

16 Table grape news

37 Technology All hands on tech

18 Prune news Prune promotions gear up

38 Profile Barry Pedersen

20 News Shocks, price surges and supply issues

39 Community Notice board

22 News Bright future ahead

39 Board members

24 News Industry's best fruit on show 26 News On the cutting edge 28 Technology Spraying solutions

The Vine is a joint publication of the Australian table grape and dried fruits industries. For editorial and advertising enquiries, contact: Dried Fruits Australia T: (03) 5023 5174 E: enquiries@driedfruitsaustralia.org.au W: www.driedfruitsaustralia.org.au Australian Table Grape Association T: (03) 5021 5718 E: enquiries@atga.net.au W: www.australiangrapes.com.au Editorial committee: DFA Anne Mansell, Megan Frankel-Vaughan, Lauren Roden ATGA Jeff Scott, Terryn Milner Design: Kylie Norton Design Printing: Sunnyland Press Cover photography: Red Cliffs grower John Hunt on his property. Photography by David Sickerdick. © Horticulture Innovation Australia Limited 2022 This publication has been funded by Hort Innovation using the table grape and dried grape levies and funds from the Australian Government. Wherever you see a Hort Innovation logo, the initiative is part of the Table Grape, Dried Grape, Dried Tree Fruit or Prune Fund. Some projects also involve funding from additional sources.

For further publication details, see page 39

Table Grapes

Dried Grapes

Combined Industries

Prunes

Hope for new season New growth and a fresh start – two things we look forward to with the coming of spring, and no more so than this year. While there is still some uncertainty heading into the new season, we hope it won’t present as many challenges as the last. Change is certainly a current theme for Dried Fruits Australia. This month we farewell CEO Anne Mansell and field officer Stuart Putland, who will both be greatly missed. Helping to lead the organisation and industry forward will be incoming CEO Thomas Cheung. The ATGA looks forward to working with DFA’s new line-up and continuing its collaborative efforts for both industries. – from the team

COVER STORY

10 Tonne Project grows Dried Fruits Australia’s 10 Tonne Project will continue for another year to put all the pieces of the high-yield puzzle together.

“That aerial imagery has allowed a

“That’s where we start to confirm

couple of even the smaller growers,

that’s how these tools work.”

The project aims to demonstrate

the whole lot.

that, with the right tools, consistently producing 10 tonnes per hectare is achievable. The first three years of the project monitored aerial imaging, fertiliser, disease and moisture monitoring data across a number of sites. “It’s important that the industry believe that this is achievable,” DFA field officer Stuart Putland said.

who knew they had some problems in patches, to realise they needed to manage to the weakest point,” he said. “If you lift the weakest point, it’ll lift

Stuart said it had become clear that consistent monitoring of the four pillars was important for consistent and continued success. “We know from experience that when

“And for the bigger guys, having more

you chuck those tools away, things get

data is helping them identify problems

out of kilter again,” he said.

and also monitor recovery.”

“If you want to get 10 tonnes, you

Stuart said it had become accepted

water it right, you fertilise right, you

that soil moisture monitoring was now

manage canopy right and you keep

a basic need in vineyard management

disease out.

tools.

“What I’m suggesting now is that any

“It’s quite obvious that all of these

new harvester built should have yield

people that are in the high production

monitoring on it to keep track of how

areas are watering their vines well –

each patch is performing.”

“While not everybody is achieving it at

they’re on top of this stuff and they

the minute, it is achievable.

know exactly what’s going on,” he said.

Measuring up

“Before this, it could happen every now

The final piece of the puzzle

and then, but people weren’t convinced that you could do it consistently.

The fourth and final year of the 10 Tonne Project will continue the work

Red Cliffs grower John Hunt has been involved with the 10 Tonne Project from the beginning and said it’s proved that consistent high yields are

“So if people believe that it can be

already established, but will also

achievable.

done, that’s a really big shift for the

include yield monitoring for the

John grows Sunglo, Sunmuscat

industry.”

coming season.

and currants and said while it was

Pillars to success

Stuart said monitoring yields would

The 10 Tonne Project has focussed on four key areas to help growers lift their yield consistently: soil moisture monitoring, aerial imaging, fertiliser inputs and disease monitoring. “What we can see now through aerial imaging is that patch management has to be spot on,” Stuart said. “You need it all producing for it to be able to work. You need to work out what’s happening in those weak spots.”

provide the final piece of evidence that aerial imagery, moisture monitoring, fertiliser programs and disease monitoring were highly valuable. He said the data from aerial imaging and yield monitoring could be overlaid to give a clear indication of yields compared to plant health. “If we can now accurately measure what tonnage of grapes is coming off, we can then overlay that with

important to select varieties that provided a good yield, managing the vineyard thoroughly and implementing a fertiliser program made a big difference to his bottom line. He said being a part of the 10 Tonne Project, in particular seeing the aerial imaging and moisture monitoring data, put a spotlight on the weakest spots of his vineyard. “I probably knew already, but it does confirm it and help me to see where they are,” he said.

Stuart said identifying the poorest

our aerial imagery to see if that’s

“I’ve got dead vines through some

producing spots was where the aerial

matching what the plants are doing,”

patches and it’s showing exactly

imaging had proved particularly useful.

he said.

where those patches are.

4 VINE MAGAZINE

COVER STORY

“There’s no hiding it.” Using the data, John now plans to shift some of his water monitors to underperforming patches to help lift the yields in those areas. Early indications from the data collected during the most recent harvest showed yield monitoring was matching what was seen on aerial imaging. “I’m normally averaging five tonnes to the acre (12.35 tonnes to the hectare) – this year is an exception – and that’s quite achievable without too much effort,” John said. “It can be done quite easily if you’re prepared to put the effort into it. A lot of people sit back and say ‘I can’t afford

this’ or ‘I can’t afford that’, but if you put the input in, you can.

modelling will again be made available industry-wide for the coming season.

“You start with a little bit and work your way up.

“Disease modelling is really important and it’s providing the industry with guidance as well,” Stuart said.

“I think a lot of it is about the varieties of vines you’ve got in. Don’t work with vines that aren’t doing the job and be willing to look at what someone else is doing – it can be done.”

Project extension supports industry The continuation of the 10 Tonne Project into its fourth year will not only develop data for industry use in the long-term, it will again deliver information direct to growers this season. The extension of the project will mean GrowCare disease alerts and

“That’s what this project has allowed us to do. It’s not just the participating sites that have benefitted from that. GrowCare information has been able to be shared with the whole industry and that will continue for the coming year.” The 10 Tonne Project, funded by the Australian Government's Murray— Darling Basin Economic Development Program, will be finalised after harvest next year. v

10 TONNE SITES YEILD 14.00

12.00

TONNES PER HA

10.00

8.00

6.00

4.00

2.00

0.00

2012

2013

2014

MERBEIN SUNGLO

6 VINE MAGAZINE

2015

2016

RED CLIFFS SUNMUSCAT

2017

2018

RED CLIFFS SUNGLO

2019

2020

LIPAROO SUNMUSCAT

2021

2022

CONFIDENCE GROWS HERE

A new level of confidence in DMI’s Belanty fungicide gives you a new level of confidence in the control of powdery mildew in grapes. Setting a new global standard for DMI’s, Belanty provides up to 100 times stronger enzyme binding than other DMI’s and is able to control resistant target disease populations. After years of research, Belanty is the breakthrough you’ve been waiting for.

Talk to your local reseller or visit crop-solutions.basf.com.au ALWAYS READ AND FOLLOW LABEL DIRECTIONS. © Copyright BASF 2021 ® Registered trademark of BASF.

NEWS

Going green S U STA I N AB I L I TY I N AC TI O N

Sustainability has become a key focus of the fresh produce supply chain. Consumers want it, and the planet demands it.

eco-friendly and sustainable

Recently innovation has taken table

of Australians have become more

completely remove plastic.

grape supply chain partners to great

mindful of their environmental impact

places in the quest for sustainable

Many table grape producers are

since the start of Covid-19, and 44

leading the charge, including Costa

and eco-friendly practices, due to

per cent of consumers consider a

Group.

mounting pressure on fresh produce

brand’s green efforts to be “very” or

suppliers to take up the fight against

“extremely” important when making a

plastic pollution and reduce their

purchasing decision.

carbon footprint.

Sustainable packaging

The pursuit of going green might

practices, but overall are environmentally and socially

“According to research the consumer will always choose board over plastic,” Michael said. “We are now seeing a

responsible.

move towards board-based trays

According to the New Daily, a recent

with plastic flow wrap, the next step

Finder report showed more than half

is using linerless label technology to

Costa entered the sustainable packaging space for grapes last season, with the launch of its 100 per cent recyclable punnet.

The 2025 National Packaging

“The base is cardboard, the lid is PET,

Targets apply to all packaging that

that has been made from 100 per cent

is made, used and sold in Australia.

recycled materials,” said Campbell

Industry targets requiring attention

Banfield, Costa’s divisional manager,

include the increase in the amount of

grape marketing.

Here, we explore some of the current

recycled plastic used, and an increase

and future initiatives and trends in

in the amount of plastic recycled.

“As there is no label (glue), the whole

industry.

These targets, combined with

The rise of the conscious consumer

shifting consumer sentiments, mean

not be a simple process, however, as preserving the environment, along with grape quality and production practices, is a delicate balance.

Consumers have generated a movement in consciousness, particularly over the past few years. Research shows Australian consumers are increasingly using their collective

businesses must demonstrate change. Michael Dossor is the group general manager of Result Group, which

punnet is 100 per cent kerbside recyclable. All components of the punnet are also produced in Australia.” Campbell said the concept for their sustainable packaging had been in the pipeline for “well over a year, from

specialises in streamlining packaging,

initial conception to production and

product identification and distribution

launch”.

processes.

“As the packaging is entirely bespoke,

power to hold businesses to account

Michael echoed the sentiments from a

all elements had to be created from

to ensure they’re not only using

packaging perspective.

scratch,” he said. “Additionally, as

8 VINE MAGAZINE

NEWS

a cardboard base was initially an unknown quantity, trials regarding shelf-life, etc., were required to ensure the integrity of the packaging and the produce inside. “Costa wanted unique packaging that would showcase our premium white seedless variety (AUTUMNCRISP®),

Covering new ground

The greater good

Alongside packaging plastics,

With consumers, governments and

agricultural plastic waste can be a

industry on a mission to reduce

challenge for primary producers.

plastics, producers have a role to

“Plastic waste is a huge problem for our primary producers in Australia,” said Dr Anne-Maree Boland, RMCG

play, according to the Department of Climate Change, Energy, the Environment and Water.

and a pre-pack allows differentiation

principal.

“Tackling the plastics problem is a

and space for consumer messaging at

RMCG is tasked with leading a

National Plastics Plan factsheet for

point of sale.

pilot program that is informing

“We chose to move to a sustainable

the development of the National

premium option, in line with consumer

Agricultural Plastics Stewardship

sentiment around eco-friendly

Scheme to recover table grape covers

packaging for their produce, and

and other agricultural plastics in order

to showcase our premium grape

to divert them from landfill.

varieties.”

“As there are limited options for

The flexibility of the cardboard also allowed for “creative elements”, with the cardboard base also opening into

recycling this type of waste, it is often

a serving platter.

said.

disposed of in harmful ways that can pollute our environment,” Anne-Maree

shared responsibility,” it said in its businesses. “Businesses can play a key role in addressing plastics through its entire life-cycle – including design, use, recovery and re-use. “Prevent – stop plastic at its source. We need to act now to reduce our plastics, and avoid plastics that cannot be recycled. “The simplest way to do this is to avoid generating unnecessary, single-use

Postharvest storage

“We know industry want to do the

and problematic plastics and design

The shift in packaging has been

right thing and this pilot provides

your products and packaging for

joined by a mission to replace

an opportunity to work with

sustainability.

other postharvest storage and

industry leaders, collect end-of-life

transportation inputs with sustainable

agricultural plastics and turn these

and eco-friendly options.

products back into new ones to help

Recyclable sulphur dioxide generating

farmers reduce waste and save

sheets are now available commercially

money.”

in South Africa, and trials have been

Growers in the Sunraysia region are

completed in Australia.

still able to dispose of old plastics for

“You can: transition away from unnecessary single-use plastics used in your business; ask your suppliers to use sustainable alternatives; shift to easily recyclable plastics such as PET (polyethylene terephthalate), HDPE (high-density polyethylene), LDPE (low-density polyethylene) and PP

“Uvasys Vivo not only reduces waste

free or arrange on-farm collection for

by protecting table grapes against

larger volumes of waste until the end

spoilage, but the polypropylene

of October. Further information and

While it can be confusing to understand

plastic sheet is fully recyclable,” said

bookings can be made at www.rmcg.

if and how these plastic types can

Gill Ambler, the Australian agent for

com.au/agplasticpilotvic

be recycled, using easily recyclable

(polypropylene).”

Tessara, which makes the Uvasys

plastic types makes the process much

product.

easier for a business, and the product’s

“Uvasys Vivo has the same active

consumer. v

ingredient as Uvasys, namely sodium metabisulphite. It, too, is a dual release sulphur pad. The first stage emits high amounts of sulphur dioxide to sterilise the surface of the berries and kills any botrytis spores. The second stage will continue to emit a low concentration of sulphur dioxide for 8—10 weeks.” The product is currently in the process of registration with the Australian Pesticides and Veterinary Medicines Authority before it can become available in Australia.

VINE MAGAZINE 9

DFA CHAIR & CEO

Changing of the guard News from our Chair This year has been a real wake up call for many growers and the processors, bringing back memories of wetter years. There is still a lot of dried fruit in sheds, and both processors are saying they will be dehydrating for weeks. Dehydrators have been in short supply and great demand and can be heard running late into the night when the temperature is reasonable.

these issues and have a plan for a

in providing a solution to labour

better way to deal with these problems

shortages and secondly in increasing

in years like 2022.

productive capacity.

News from our CEO “The times they are a changin’” – so goes the song by Bob Dylan, and that’s certainly true for Dried Fruits Australia. In this, my last column as CEO, I’d like to introduce incoming CEO Thomas Cheung and offer my congratulations

The DFA office is also seeing some transitions. Industry development officer Stuart Putland is moving on to other roles and will be very much missed by the dried grape industry. Stuart’s energy and facilitation skills have encouraged new opportunities, with growers learning from each other on farm, in sheds and at the office. Sharing ideas and working collaboratively is extremely important

Brown fruit will make up a high

and a hearty welcome. Thomas has

percentage of the fruit delivered this

a lengthy career and comprehensive

year. While total tonnages for 2022

experience in the dried fruit and nut

were not known at the time of writing,

industries and will bring a wide range

estimates were around 15,000 tonnes.

of skills to DFA.

I’d like to thank Mark, the board and all

Pruning is well underway and canes

Transition is important for all

are looking good. I have been hearing

industries. Over the past five-and-a-

for their support and encouragement.

labour is still a major issue. DFA and

half years, the dried grape industry has

some growers are looking at different

seen a critical transition in researching

ways to cut costs. There is some great

and implementing the mechanisation

work being done and I urge growers to

of winter pruning.

keep an eye on Currant News to find out about any workshops.

Alongside this work, DFA has been fortunate to receive funds from the

We must remember that this is the

Department of Agriculture, through

first time in many years that numerous

the Murray-Darling Basin Economic

incidents made it such a hard year: low

Development Project to discern how

temperatures, rain, unreliable weather-

agri-technology can provide key

forecasting, a shortage of bins, LPG

data to assist with yield and on-farm

and bottle availability for dehydrators,

performance. These are two important

and labour. We should be looking at

transitions for the industry, firstly

Mark King | Chair

10 VINE MAGAZINE

in sustaining and growing an industry, and Stuart has been an incredible contributor to the DFA team.

the wonderful staff I’ve worked with While small, the DFA team works diligently for our growers, processors and other stakeholders. I can’t thank you all enough. I believe there are significant prospects ahead for the Australian dried grape industry, with strong demand for the best quality dried grapes in the world. I wish all involved in this historic and innovative industry all the best for the future.v

Anne Mansell | CEO

DFA NEWS

New beginnings It’s been a long, drawn-out harvest for a lot of us. The weather was not kind and only those with a cut-and-harvest-early

If you haven’t already had a chance,

success if people in the industry are

you can view David’s talk on the

actively involved. I will still be around

twin cutter system at DFA’s YouTube

and if anybody wants to catch up,

channel.

perhaps a meal at the Gold Diggers —

strategy got through without the

Our second on-farm event was also

stress of dealing with rain during the

popular, with more than 30 people

drying season.

turning up to Warren Lloyd’s place

One note on the brighter side is that varieties like Sunmuscat and Sunglo have certainly handled the wet conditions much better than our old nemesis, sultana. Despite the drawn-out harvest, there have been a number of activities go ahead in the Dried Grape Production Innovation and Adoption Program. Our first on-farm event for the season was driven by Red Cliffs grower David Lyons. The focus of the event on his property was to reflect on a difficult harvest and a reduced availability of harvesting contractors with a discussion around the pros and cons of a range of harvesters, a new look at summer pruning and even trellis design. Five growers brought their harvesters to the afternoon session and led the discussion, with the 35 growers who attended, on their relative benefits. David outlined the benefits of his twin

to look at Warren's and Ashley Johnstone’s new approach to

03 5023 5174 projects@driedfruitsaustralia.org.au

mechanised pruner. It was a great opportunity for everybody to get a look at how the pruner worked. We could clearly see the LiDAR modelling system mapping the cordon in three dimensions and then guiding the cutting head to a set distance away from the edge of the cordon. Obviously, there is still some work to be done and experience gained with integrating this technology into the production system, but it was clear from the day that the modelling and control systems are very nearly a reality that dried grape growers can now begin to use. As many of you will be aware, this is my last column as DFA’s industry development officer.

and some potential improvements to

to work in and the team at DFA have

swing arm trellis design to allow more

been outstanding to work with. During

room for error in the summer pruning

the past five-and-half years I believe

process.

the industry has made significant

swing arm to the post and introducing

Dried Fruits Australia field officer

La Trobe University-designed DFA

This has been a wonderful industry

a slightly longer bracket linking the

Stuart Putland

mechanised pruning and see the

cutter system for summer pruning

David has begun experimenting with

my favourite pub. v

progress, and focus on consistently achieving 10 tonnes per hectare will help drive more success.

a five-degree angle in the middle of

Thank you to all who have helped

the swing arm, all of which combine

me deliver the DFA Hort Innovation-

Top: David Lyons’ twin cutter summer pruning set up.

to create a bigger gap between the

funded Innovation and Adoption

arm and the post for summer pruning

Program. There are too many to list

without impacting the geometry of

here but it is important to recognise

the swinging system.

that this sort of program is only a

Middle & Below: Demonstrated with the DFA pruner were the manually controlled cordon pruner and topping/skirting cutter system both Ashley Johnstone and Warren Lloyd have been using this season.

VINE MAGAZINE 11

ATGA CEO

Hope for a budding future News from our CEO It feels like growers were just pruning, but buds will emerge soon and a new season will be upon us.

Markets

Fruit fly

The ATGA has increased its

A number of workshops have been

communication with the Australian

held in recent months concerning fruit

Government about improving access

fly activity. Recent outbreaks in the

into the United States and Japan.

Riverland have become more frequent

Last season was difficult and challenging for everyone, by most accounts. The challenges faced by all can be attributed to several factors, but none more so than the lingering effects of the pandemic.

At a recent bilateral meeting between

Internationally, China had lockdowns in Shanghai and Beijing – during the most important period of the harvest – and all other countries had restricted movements, which one could argue led to lack of consumer confidence and spending. Importers were, simply, not at the confident level they were pre-Covid.

to conclude its work on mangoes by

Climatic conditions did not help, with overcast and humid times during critical growth periods, compounded by two bouts of La Niña. This was a major contributing factor to the quality of fruit produced this year and the lateness of harvest, compared to previous years. There is some uncertainty, with rare triple La Niña predictions for the next season. However, with a 50-50 chance, we hope weather patterns are in our favour, and the industry can look forward to next season’s harvest with some amount of confidence.

Australia, the Japan importers association, and the Japanese government, it was pleasing to hear that Japan’s Ministry of Agriculture, Forestry and Fisheries (MAFF) expects October. It should then commence work on Australia’s next priority for access, which is set to be additional varietal

Pest Free Area status. This will have an impact on the way fruit is exported from the Riverland. There is also the concern of the odd Mediterranean fruit fly (Medfly) outbreaks in Adelaide. All eastern states in Australia are deemed Medfly free, and it is important that the state governments continue their surveillance programs

access for table grapes and citrus.

on Medfly.

Japanese importers suggest they

Several protocols rely on the East/

would like the next priority to solely be table grapes, which is good news for the industry. While it is difficult to put timelines on the conclusion of these activities, assuming no unforeseen circumstances, I hope these negotiations will conclude between Australia and Japan by December 2023, in time for the 2024 export season.

West conditions for fruit fly. The West is free of Qfly and the East free of Medfly. This status needs to be maintained. So, it is a timely reminder that all growers should be vigilant for Qfly in their vineyards. The extension team is on hand if you need support or advice on bait spraying and trapping for Qfly on your property. In autumn, record numbers of Qfly were detected

The ATGA has engaged the US embassy

in traps in Sunraysia, due to abnormally

in Australia to hasten a response

humid conditions. While Qfly numbers

from the United States Department

fell over the cold winter, they're

of Agriculture (USDA) for improved

expected to increase during spring

access to the US. Let’s hope Australia

with the warmer weather. You can read

gets a response from them soon.

more about fruit fly on pages 31-33. v

Jeff Scott | CEO

12 VINE MAGAZINE

and there is fear that it may lose its

ATGA NEWS

Active over winter Pests may have been overwintering, but our team has certainly not. Over the past few months, we’ve kept busy on several fronts, with travel and events, trials and tests, technology, and biosecurity. Vine health session In June, Jeff, Alison, and Karen made the trip to Western Australia to connect with table grape producers and host a vine health workshop in collaboration with the Department of Primary Industries and Regional Development (DPIRD). The ATGA was grateful to draw on the wealth of knowledge of its WA presenters, hosting DPIRD senior technical officer Colin Gordon, and research scientist Andrew Taylor, as well as University of Western Australia research fellow Roberto Busi, and Scott Paton, Nutrien Ag Solutions' product development agronomist horticulture. Around 40 producers and industry service providers attended the hybrid session, in person in the Swan Valley and in Carnarvon, and more joined us online. Even some high school ag students participated in Carnarvon. The agenda for the half-day event was jam-packed with topics. The morning began with discussions on chilli thrips, trials with automatic weather stations, the history and reasoning behind the loss of some of the industry’s old chemistry and new chemistry options, and the importance of application timing. After morning tea speakers explored the increase in herbicide resistance, and powdery mildew resistance. Alison had an interactive discussion on the challenges of configuring sprayers to suit table grape canopies. Finally, the session finished with a presentation on mealybug trials.

It was great for us to connect with producers in their vineyards, to discuss matters impacting production, such as pest and disease pressure, water, trellising systems, marketing, auditing and social licensing.

Restricted spring growth (RSG) The team held face-to-face information sessions back in May, in Robinvale and Mildura, to discuss analytical results so far. Producers were able to ask questions about RSG and give feedback on next steps. In the continued hunt for an answer to RSG, we collected bud sticks for bud and rust mite assessments from multiple vineyards throughout Sunraysia, Euston and Robinvale. In summary, mite numbers varied greatly between patches; the variation is too great to make any direct link between mites and the observed RSG. The team will bring mite experts together in an online session to discuss the results and plan the next steps in the assessment of mites and RSG.

Biosecurity It’s important that as an industry we stay current and informed on the latest research and thinking around biosecurity in Australia due to the impact any exotic incursion can have. In May, Jenny and Karen attended the Plant Biosecurity Research Symposium in South Australia. Australian and international speakers addressed topics such as response actions and responsibilities, current research, new surveillance systems and cutting-edge field-based technologies. We came away from the symposium with a much better understanding of these initiatives, and a wider network, with vital connections in government and research organisations.

Chemistry

dormancy, are under review and some will inevitably be discontinued. As this will leave producers potentially without their favourite chemicals, the team is on the quest for alternative chemistry options compatible with integrated pest management (IPM) production practices. We are currently implementing two demonstration trials: a postharvest spray application trial to, hopefully, reduce overwintering mealybug populations; and a trial of alternatives to Dormex®. The mealybug trial will investigate whether drenching crowns and cordons does greatly reduce early season mealybug populations, and whether adding adjuvants improves the efficacy of crown drenches. We will return to the demonstration trial in spring to count mealybugs and assess the effect of drenching. The second trial was established to compare Dormex® with nine other dormancy breakers coming onto the market. The team hopes to shed some light on those alternative options later in spring, when bud counts and data analysis are finished. Stay tuned!

Involved & informed We would like to thank the producers and presenters who made the effort to attend, present, ask questions, make suggestions, and provide feedback at the various RSG and vine health sessions. Thanks also to producers for making the time to walk and talk with us in your vineyards keeping us informed and up to date with your individual thoughts. Please keep your phone calls coming and let us know of any issues or ideas you may have! v Alison, Jenny, Karen

Quite a few chemicals widely used to combat pests and diseases, or to break

VINE MAGAZINE 13

DRIED GRAPE NEWS

Innovation key for future The Dried Fruits Australia board has established a Grower Innovation Group to collaborate on innovation in dried grape production. The board sub-committee was formed at the July board meeting with the aim of tackling grower challenges. Board deputy chair and Grower Innovation Group member Warren Lloyd said the group had narrowed its focus for the coming year. “What’s become apparent is that there’s a desperate need for new harvesters to be built specifically for swing arm trellis,” Warren said. “We’re trying to come up with constructive solutions to this problem.” The group will have professional drawings created of what they regard as a best practice machine. “Ideally our aim is to see a new harvester constructed and used for the 2023 harvest, which is a pretty tall order, but that’s the goal,” Warren said. Another challenge is the capacity

of existing wetting machines to adequately wet large crops. “When these were designed, a big crop would have been three tonne to the acre (7.41 tonnes to the hectare), whereas you’ve got people now who are averaging five tonne to the acre (12.35 tonnes to the hectare) and finding it difficult to get an adequate wetting job done,” Warren explained. The Grower Innovation Group welcomes more members from the dried grape growing community. “There’s a willingness to contribute and if you’ve got multiple people in a room, you can come up with more options. It’s a great starting point” he said. The Grower Innovation Group was established as the board prepares to sign off on the DFA Strategic Plan 2022-2027. The board met in May to review the plan and update for the next five years. With a range of background information, including the new Hort Innovation Dried Grape Strategic Investment Plan 2022-2026, and with research and development priorities

from the planning day held in January 2021, the board focussed on critical issues to the industry, such as supply, production systems, investment and market engagement. Leonie Burrows facilitated the session as the board explored key challenges and opportunities for the industry. Research, development and extension, and communication of R&D information to growers remains a strong focus, along with production efficiencies and industry sustainability. The vision is for “a profitable and sustainable industry delivering innovative growth and quality dried grapes” with three major goal areas encompassing industry, market development and the organisation itself. The DFA Strategic Plan 2022-2027 will receive sign off at the board’s August meeting. People interested in joining the Grower Innovation Group can contact Warren at manager@18ninety.net or by phone on 0417 851 004. v

D I G I TA L S PRAY D I A RY R EA DY F O R TH E S EAS O N Dried Fruits Australia’s chemical spray diary is now digital. Contracted dried grape growers would now have received their login details for the Grapeweb platform, which houses the new spray diary. Industry field officer Stuart Putland said Grapeweb had significant experience in tailoring a program suitable for the wine grape industry, which was able to be adapted for dried grape growing.

simply log on and have a go. “It’s easy to use and there are how-to videos available on the site to show how everything works,” Stuart said. “Growers need to enter details about their individual patches – row spacing, planting dates and varieties. If people are unsure about their hectares, SunRISE Mapping might be able to help,” Stuart said.

“If we have any growers who have experience with wine grapes, it’ll be familiar to them.”

The platform includes inputs for chemical user permits and sprayer calibrations, and all chemical information links to the Australian Pesticides and Veterinary Medicines Authority, where product labels and safety data sheets can be found.

Growers have been encouraged to

Grapeweb includes the DFA-approved

“They’ve run this system for a long time,” he explained.

14 VINE MAGAZINE

list of chemicals and gives simple alerts if growers have chosen a spray that doesn’t match the application. “It’ll allow you to search for chemicals to treat for a particular pest or disease, and it’s got all the withholding periods specific to dried grapes,” Stuart said. Hard copy spray diaries are available free for members ($15 for non-members) from the DFA office. The Grapeweb system will work on iPad, computers and phones. Processor field officers are trained in the system to support growers, while Grapeweb can provide technical support. The project was funded by the Australian Government.

DRIED GRAPE NEWS

Mapping our industry SunRISE Mapping and Research is offering free crop plans to dried grape growers. Crop plans are a useful property record particularly for planning, quality assurance purposes and industry contracts. The free crop plan offer aims to facilitate data sharing between SunRISE and processors for improved industry planning and management. All individual property data– including plantings and production data – will be treated in the strictest of confidence, and only aggregated, de-identified data will be released. SunRISE Mapping and Research program manager Sue Argus said SunRISE had mapped dried vine fruit across Sunraysia and the Riverland for 25 years. “The process involves preparation of crop plans for growers and preparation of industry-wide information on the production base for Dried Fruits Australia,” she said.

“SunRISE aims to maintain the accuracy of data on dried vine fruit plantings and seeks input from growers to verify and update their plantings data, in particular to capture the uptake of new varieties and clarify transition between wine, dried and table grapes.”

For your free crop map or more information, contact Julie at SunRISE Mapping and Research by calling (03) 5021 3156 or email mapping@sunrisemapping.org.au

Sue said both SunRISE and processors maintained separate databases for dried vine fruit growers. “The ability to share data requires the permission of growers and this would greatly enhance efficiencies in data management and quality of industry information,” she said. The crop plans have a background of aerial imagery flown from January to February 2021. The imagery is scale accurate so hectares and/or acres are calculated from the mapping. The maps will be supplied as one hard copy print, A4 paper size, and a digital PDF version. The offer is available until 30 June 2023. v

“Suppliers of improved grapevine rootstock and scion wood to the grape industry” Contact Gary Thomas Tel: (03) 5022 8499 Mob: 0418 997 730 PO Box 5051, Mildura Vic 3502 Email: vamvvia@bigpond.com Please see website for more information & order forms www.vamvvia.org

VINE MAGAZINE 15

TABLE GRAPE NEWS

Promise against misfortune Exports held strong across the 2021/22 season, despite several challenges faced both on the home front and internationally. Australian Table Grape Association CEO Jeff Scott said it was pleasing to see export results like this despite the challenges on all fronts. China fell 38 per cent to 26,801 tonnes for a market share of 24.2 per cent.

Exports to Vietnam increased 95 per cent, from 7018 tonnes to 13,699 tonnes (and a 120 per cent increase on value, from $34.54m to $75m).

- 35 per cent increase in exports to Malaysia

Other highlights from the preliminary Australian Bureau of Statistics (ABS) results released to the ATGA in late July included:

Positively, price per kilogram stayed strong, increasing from $3.82 for the 2020/21 season to $4.06 for 2021/22.

- 25 per cent increase in volume to both Thailand and New Zealand.

- a 69 per cent increase in export tonnage to Singapore and Bangladesh - 45 per cent increase in exports to Taiwan

WHO’S BUYING MY FRUIT?

n 1.8% Taiwa .4% ia 2 % lays 3.1 Ma ore gap Sin

Ho ng Ko ng NZ 3. 3.6 4% %

UAE 1.4% Bangladesh 0.6% Qatar 0.3% Fiji 0.2% New Caladonia 0.2% China 24.5%

Sth Korea 3.7% Thailand 7.1%

Phillipines 7.7%

Indonesia 18.3% Japan 8.8%

16 VINE MAGAZINE

Vietnam 12.4%

TABLE GRAPE NEWS

$

Volume

Value

$ per kg

110,916 tonnes

$450.02 million

$4.06

-8.1%

-2.3%

+6.3% 0.24c

AUSTRALIAN TABLE GRAPE EXPORTS 10 YEAR TREND VOLUME AND $ PER KG

160,000

$4.50

140,000

$4.00

Volume exported (Tonnes)

$3.00

100,000

$2.50 80,000

$2.00 60,000

$1.50

40,000

$1.00

20,000

0

$ per kg (AUD and USD)

$3.50

120,000

$0.50

2011/12 2012/13 2013/14 2014/15 2015/16 2016/17 2017/18 2018/19 2019/20 2020/21 2021/22 VOLUME

VALUE AUD/KG

$-

VALUE USD/KG

Source: ABS (2021) via IHS Global Trade Atlas; Fresh Intelligence Analysis

VINE MAGAZINE 17

PRUNE NEWS

Prune promotions gear up Australian Prune Industry

the Good Food & Wine Shows (GFWS)

and that the exhibitors seemed to be

Association promotions

after a two-year absence,” he said.

having a good show”.

ramped up during the month

Cassandra Cadorin from Candid

More than 21,700 people attended

of June to focus on a range of

Marketing co-ordinated the

the Melbourne event over the three

promotion, which began with social

days, while in Sydney there were

activities, including the Good Food & Wine Shows (GFWS) in Melbourne and Sydney, The Cook Up with Adam Liaw on SBS Food, and continuing social media.

media invites to visit the Ausprunes stand at the GFWS in Melbourne and

almost 25,900 visitors.

Sydney, and a competition to win

The Ausprunes stand was located in a

free tickets to the event by tagging a

prime position, close to the entrance,

friend and registering.

which helped increase visibility and

This was a new initiative from APIA,

attract visitors.

which Cassandra said had more than

Growers Frank and Lucy DeRossi and

APIA promotional spokesperson

104 responses for the Melbourne

Peter Raccanello volunteered at the

Peter Raccanello said Covid-19

show and 325 for the Sydney show.

Melbourne show, while APIA chairman

lockdowns and dining restrictions

GFWS were cancelled at the last

Tony Toscan and granddaughter Laura

presented the ideal opportunity to experiment in the kitchen.

minute in 2021 due to Covid-19

were at the Sydney show with growers

restrictions, and the passionate

Jordan and Amanda Adams and

“The result has been a real thirst for

foodies returned in 2022.

Jordan’s parents, Robert and Michelle.

recipe ideas and new ingredients,

Organisers for the event reported

Tony said that it was a real benefit

particularly those that are Australian

that the Sydney show “felt organised

having growers at the event as visitors

grown, so it was great to get prunes

and busy, but not overcrowded in the

to the show loved to engage with

out in front of consumers again at

aisles like it could be sometimes,

those at the stand.

18 VINE MAGAZINE

PRUNE NEWS

“Our stand had five enthusiastic

Peter said it was also great to see

Wednesday 29 June. It is available on

people all day including Cassandra. We

Yenda grower Ann Furner promoting

SBS On Demand, so look for The Cook

conveyed our usual messages about

her Naturally Dried Prunes at the

Up with Adam Liaw Season 2, Episode

the health benefits of prunes as well

show.

73. v

as their versatility as an ingredient in

“It further demonstrates the

This activity was jointly funded by

lots of recipes or as a simple snack,” he said.

versatility of prunes and is an excellent promotion for the industry,”

“In contrast, a fresh produce stand

he said.

near ours was manned with hired

“Another unexpected opportunity

staff. It received only a fraction of the

arose when the smelly cheese stand

visitors that we did.”

ran out of sultanas to accompany their

Tony said 30 to 40 per cent of visitors to the stand were Asian women who just loved prunes and trusted in the Angas Park and Verity Fruits brands. About 6000-8000 snack packs supplied by Angas Park Fruit Co and prune samples from Verity Fruits

Angas Park Fruit Company, Verity Fruits and APIA.

cheese, and prunes were asked to step in. It just shows what a flexible accompaniment prunes can be.” All participants agreed that there was much to be gained from interacting with the visitors to GFWS and sharing the prune experience.

were handed out at each event so

The prune-themed ingredient episode

that people could sample Australian

on The Cook Up with Adam Liaw

prunes, some for the first time.

went to air on SBS Food channel on

Opposite page: All set up and ready for action at the Melbourne GFWS, Cassandra Cadorin, Frank and Lucy DeRossi and Peter Raccanello. Left: An unexpected opportunity to share prunes with the smelly cheese stand. Below: APIA Chair Tony Toscan on hand to share his knowledge of prunes with visitors to the Sydney GFWS.

In Melbourne, Peter was delighted to see people walking around the show snacking on prunes, and particularly pleased to see kids sitting in prams developing a taste for the dried fruit. “There are a still a lot of people out there who just think of prunes as being a laxative for the elderly," Peter said. "They don’t realise that you can cook with prunes in a variety of sweet and savory recipes, or that they are delicious by themselves as a simple, healthy snack.” “The recipe video was a hit and Cassandra organised a competition to win a year’s supply of prunes by signing up to our database to receive weekly recipe ideas. Almost 200 people signed up in Melbourne and over 470 in Sydney, which shows that people are keen to consume prunes and learn about interesting ways to use them.”

VINE MAGAZINE VINE MAGAZINE 19 19

NEWS

Shocks, price surges and supply issues Disruptions and elevated costs are set to continue for the global shipping sector. Shipping sector challenges are expected to continue for at least

The WSC predicts that this situation

costs and up to 100% in wood pallets

will normalise once consumer demand

prices.”

stabilises and new containers enter the market – a 4 per cent increase in vessel capacity is expected for 2023.

While the record-breaking rates for shipping have begun to soften, the RaboBank report stated, and “spot

While the end might be in sight, it’s

rates having retreated from irrational

been a hard slog for exporters, says

high levels in Q4 2021” – they remain

the Southern Hemisphere Association

three to five times above pre-2020

of Fresh Fruit Exporters (SHAFFE).

levels.

global container freight prices are

“Southern Hemisphere producers

Long-term contract rates have

set to continue to gradually decline

estimate an increase of costs by 3.8

also risen significantly and remain

over the coming 12 months – from the

billion USD through the increase of

elevated, it said.

outrageous highs reached last year

container prices by round about 150 per cent for 2022,” SHAFFE said in a

The WSC has underlined that it isn’t

– they are not expected to return to pre-pandemic lows.

July declaration.

The shipping industry has been

“While the sector demonstrated its

impacted by wider influences,

resilience during the past two years

including weaker global economy

of the COVID pandemic, the current

and consumer confidence, higher

global supply chain challenges have

operational costs, geopolitical

been leading to cascading negative

uncertainties and imbalanced trade

effects for all parts of the industry.

another year, despite a flicker of light at the end of the container. According to RaboBank’s Global Ocean Freight Outlook report, while

flows.

capacity the “traffic jams” will still

costs in multiple areas including: 150-

Council (WSC) identifies, have been

400% in container prices, 20% in truck

unprecedented – but there is a glimpse

transportation up to 80% in airfreight,

of hope for exporters.

up to 100% in, up to 100% in fertilizer

20 VINE MAGAZINE

exist. v

“The sector has experienced increased

These “shocks”, the World Shipping

4 per cent increase of vessel capacity expected by 2023

a quick fix – as even with greater

Prices set to decline over the next 12 months, but remain above pre-pandemic rates

Geopolitical uncertainties still exist

Low consumer confidence and heightened inflation still exists

Imbalanced global trade flows removing container capacity from network circulation

Growing operational costs from energy and sustainability regulations

Prevent powdery mildew and botrytis in one pass.

NEW

Produce healthier and more saleable bunches with Luna® Experience fungicide. • Provides powdery mildew and latent botrytis control* • Built-in resistance management with Fungicide Groups 7 & 3 in one formulation, no need to tank mix • Soft on most beneficial species*

Speak to your advisor or visit crop.bayer.com.au to find out more. *When used as directed. Bayer CropScience Pty Ltd ABN 87 000 226 022. Level 1, 8 Redfern Road Hawthorn East VIC 3123, Australia. Technical Enquiries: 1800 804 479 enquiries.australia@bayer.com Luna is a Registered Trademark of the Bayer group.

NEWS

Bright future ahead The dried grape industry has a bright future, according to retiring CEO Anne Mansell, who has reflected on her time in the position and shared her hopes for the future of the industry.

me, and worked on various friends’

Anne said DFA’s field officer Stuart

properties picking and doing racks,

Putland had the technical dried grape

driving tractors and the like.”

growing knowledge, which meant she

In looking back at her five-and-a-

could focus on being “strategic in

half years with DFA, Anne hoped her

where we wanted to take the industry”.

legacy would be her work fostering

“At the time I started in the role, it was

collaboration across the industry.

really about making sure we expanded

“I think the key for any industry to

the export market and getting the

Anne joined Dried Fruits Australia in

move ahead and move forward has

price parameters right,” she said.

February 2017, bringing with her a

always been to work together,” she

“It was about trying to get that price

wealth of experience in policy, politics

said.

kicked up so growers would stay in

and regional development – as well

“Between us all here – our team here

the industry. To do that, the focus was

as an upbringing surrounded by fruit blocks.

at DFA – that’s what we’ve really tried

on increasing exports, because that’s

to foster by working with our growers

where the high price was at that point

“I was brought up next door to a dried

and our processors collaboratively to

in time.”

grape and citrus packing shed,” Anne

hopefully bring a more positive future to the industry.

Anne worked closely with processors

said. “My mum’s family and my dad’s

“It’s about lifting everyone so the

for Australian dried grapes. Germany

family had both been in dried grape

whole industry can be performing at

and Italy had been “classic markets”,

production, but my parents weren't.

a high level and therefore benefit the

but Anne was keen to see what

But I grew up – like everyone else

local economy, regional economy, and

opportunities existed for the industry

around here – with it surrounding

the greater Australian economy.”

in Asia.

and growers to find the best markets

"I think there's a strong positive future for our industry. We might be small, but at the end of the day we're kicking some great goals."

Thomas Cheung and Anne Mansell

22 VINE MAGAZINE

NEWS

“We went to a lot of specific trade

that’s been a tremendous highlight,”

and all stakeholders. There’s so

shows to benefit dried grapes. That

she said.

much enjoyment for me in working

DFA chair Mark King said it had been

with them together, facing up to the

was a really interesting process, and we made inroads there,” Anne said of connections made in China, Singapore and Vietnam. “We did all that exploration and got those markets in place, and then Covid hit.” The pandemic put a stop to some of that market exploration and expansion work, and it coincided with an increase in table grape plantings and transfer of dried grapes to table grapes, reducing the industry tonnage. While this forced exports to be scaled down, market demand remains high, placing the industry in a positive position for the future, according to Anne. “We do produce the best quality in the world,” she said. “The market demand is really strong for our dried grapes. It’s a matter of getting that consistency of supply so we can support those markets.” Anne said DFA initiatives including the 10 Tonne Project, benchmarking and yield monitoring – in addition to new investments supported by the GrapeInvest modelling tool – would help to grow consistency of supply to help support market demand. “I think there’s a strong positive future for our industry,” she said. “We might

a pleasure to work with Anne, who had achieved a lot in the role. “With her passion for the industry, willingness to learn and consider all views put forward, we have pushed to grow the industry,” Mark said. “Anne has a great rapport with people – from growers and the board to politicians – and has built a great team. “Her team has been very active and successful in securing grants to fund initiatives like the 10 Tonne Project, which I believe is the reason why new growers have joined the industry.

the Australian dried fruit industry, working collaboratively to build a sustainable, innovative and prosperous industry for many new generations to come. “Under the strong leadership of the DFA board and CEO Anne Mansell, it has led so many highlights and achievements. It is my honour to continue such success and to further improve it.” v

Anne and Mark agree DFA is in good hands under incoming CEO Thomas Cheung. “Thomas has a great understanding of the markets and of the industry itself,” Anne said. “He has a degree in economics, and he understands how regional economies work – there’s a lot of great knowledge and expertise he’ll bring to this role.”

forward to contributing more and working with the people who make up the industry to “strategically build a brighter future”.

one of the most recent developments

“I have been involved with the dried

in mechanised pruning.

fruit industry in one way or another

“From an idea to get us to full

always be the major force in leading

New growth

fruits industry, Thomas is looking

ideas for what was needed, including

“DFA has always been and will

the last five or so years!”

we’re kicking some great goals.”

alongside industry to come up with

fruitful season.

School, we’ve done pretty well over

Having started his career in the dried

her time with DFA was working

and having joyful laughs after a

“For two kids from Coomealla High

be small, but at the end of the day, Anne said one of the highlights during

challenges, overcoming difficulties,

for over 22 years,” Thomas said.

mechanisation, to now seeing a pruner

“I am in love with the people – growers,

that’s actually out there working,

processors, customers, suppliers,

VINE MAGAZINE 23

NEWS

Industry’s best fruit on show A high standard of fruit was submitted to this year’s Dried Fruit Quality Awards, during one of the most challenging seasons faced by the industry.

“2022 will go down as one of the hardest seasons, but due to growers changing to rain tolerant varieties – which now make up more than 50 per cent of dried grapes produced – the industry will come through,” Mark said. “Many growers are also following

The winners of Dried Fruits Australia’s

DFA’s updated best practice guides,

annual awards were announced at

which assist with decision making

Mildura Field Days on in May, with

throughout the key phases of dried

awards presented for the best

grape production.”

sultanas, raisins, currants, Sunmuscat and Sunglo, as well as an overall winner. Merbein growers Janice and Simon Chivers took home the top award for the season’s best dried grapes for their sultanas. Terry Hunyadi from Birdwoodton won best currants, Angie Panagiotaris from Mildura won best raisins, Sam Costantino from Mildura South won best Sunmuscat, and Stephen and Jinky Nicholls from Coomealla won best Sunglo. DFA chair Mark King said the winners all produced high quality fruit despite the difficulties faced by growers over the season.

24 VINE MAGAZINE

Dried grape grower and DFA board member Stephen Bennett, who judged this year’s entries, said the newer sultana-type varieties Sunglo and Sunmuscat held up well this season, while Carina currants were also of a very high quality. “Overall, the standard of this year’s entries was excellent considering the adverse weather conditions the industry experienced this year,” Stephen said. “It demonstrates how far the industry has come in developing production systems that can turn out quality product even in difficult seasons.” v

2022 Dried Fruit Quality Awards winners Best dried grapes of the season, Best sultanas Janice and Simon Chivers, Merbein (Sunbeam Foods) Best currants Terry Hunyadi, Birdwoodton (Australian Premium Dried Fruits) Best raisins Angie Panagiotaris, Mildura (Sunbeam Foods) Best Sunmuscat Sam Costantino, Mildura South (Sunbeam Foods) Best Sunglo Stephen and Jinky Nicholls, Coomealla (Sunbeam Foods)

NEWS

Top crop reaps rewards

Allan Long has taken out top honours in the inaugural Dried Fruits Australia Top Crop Awards. The new awards program aimed to recognise the dried grape industry’s best producing businesses, highlighting those that produce the highest value crop per hectare. “These awards are primarily driven by yield, but they also take into account the price received, which is based on quality,” industry field officer Stuart Putland explained. “Congratulations to all of these winners for producing such tremendous yields in what ended up being a very difficult season.” Allan’s patch of Selma Pete, with a yield of 15.815 tonnes per hectare, was the overall winner. He attributed his success to a number of factors, including his narrow

Allan produces his Selma Pete in narrow, 7ft (2.1m) rows, down from the traditional 11ft (3.4m) row, which he said was one of the bigger impacts on the end result.

“Narrower row spacing gave our winner

“The other part of it is getting better and better at managing inputs – water and fertiliser,” he said.

“It will be interesting to keep an eye on

“There has been some guidance coming out of the (DFA) benchmarking study, but generally, I downsized about three years ago, so that gave me an opportunity to concentrate more on this one property. It’s a combination of a lot of things.

in this closer row spacing if this is an

“A lot of little things have got to be right to succeed really well.”

that Ashley’s vines produced a higher yield per vine or kilometre of cordon,” he said. results of this competition in future years because there may be something ongoing trend.” The overall Top Crop Award winner received a $500 Mildura City Heart gift card, while category winners each received a $100 Mildura City Heart gift card. v Top Crop Awards winners

Allan said while he had been achieving good yields for some time, he experienced a jump this season.

Overall and Selma Pete:

“I’m hoping it’s an indication of what the normal yield might be in the future,” he said.

David Lyons 12.231 t/ha

managing water and fertiliser, and a

Stuart said an honourable mention must go to Ashley Johnstone for his Selma Pete yield of 11.64 tonnes per

warm spring the year before.

hectare.

row trellis system, a keen focus on

the edge, notwithstanding the fact

Allan Long 15.815 t/ha Sunmuscat: Currants: Daryn Gardner 13.644 t/ha Sunglo: John Hunt 10.796 t/ha

VINE MAGAZINE 25

NEWS

On the cutting edge The inaugural Growing Smarter in the Mallee ag tech summit brought about 250 people together to see and discuss some of the cutting-edge technology and innovations being used to address industry and regional challenges. An initiative of the Mallee Regional Innovation Centre (MRIC), the event was held at the SuniTAFE Smart Farm in Irymple on 5 and 6 May. MRIC CEO Rebecca Wells said the event allowed people from across different industries to come together and learn from each other, with people attending from other regions, Melbourne, Adelaide, and as far away as Brisbane. “We started out with an idea of bringing an event to the region – one that you would normally find in a capital city,” Rebecca said.

26 VINE MAGAZINE

“We wanted to put something of scale together and make it accessible. “There is lots of information and technologies out there, and this event opened a door for people to be able to hear from and follow up with the researchers and providers who spoke at panel sessions, were at the trade stalls, or were demonstrating equipment.” One of many innovations showcased at the event was the dried grape mechanised pruning prototype, which is being developed by Dried Fruits Australia and MRIC partner La Trobe University. Attendees also got to see and learn about other prototypes, patented applications, and the latest innovations and influences on industry, including options for data collection, traceability, and what energy may look like in the future. The Australian Table Grape Association CEO Jeff Scott gave

a unique insight into the table grape traceability pilot, alongside technology provider Result Group. Rebecca said the event really highlighted what an exciting time it is to be in horticulture. “You could listen to a panel session with speakers and then head out of the tent and see a practical demonstration, go on a farm tour, attend a workshop or visit a trade stall to get the depth of knowledge for what you were interested in,” she said. “A delegate approached me at the end of the event and said how they had thought all these things were theoretical. But in fact, it's not. It's happening now. “For that grower, it really changed how they were viewing future tech and its applications for industry.” v

Keep grape pests pinned down. Stop the pests wherever they’re hiding in your grapes, with the two-way systemic action of Movento®: •

Protects the whole vine

•

The only registered Group 23 insecticide

•

Low impact to most beneficials, when used as directed

With long-lasting protection, Movento can be effectively used as part of your integrated pest management program. To learn more and to download the grapes crop guide, visit crop.bayer.com.au/movento or talk to your local Bayer Crop Science representative.

Movento® is a Registered Trademark of the Bayer Group. Bayer CropScience Pty Ltd ABN 87 000 226 022. Level 1, 8 Redfern Road, Hawthorn East, VIC 3123, Australia. Technical Enquiries: 1800 804 479 enquiries.australia@bayer.com

TECHNOLOGY

Big and small spraying solutions Effective agrichemical spraying is a necessary part of vineyard management for any table grape grower. If you could reduce chemical waste, reduce financial outlay, reduce your vineyard’s carbon footprint, improve coverage and reduce your time – or your workers’ – on the job, that would be the definition of utopia. Wouldn’t it? Growers might think these are grape expectations, but they are achievable. Here we explore both minor and major changes you could make to your vineyard spray practices, and take a look at how these might benefit you.

Recycling sprayer Growers who attended the Australian Table Grape Association’s first event in the “AgTech Sessions” series in July would have seen a recycling/ recirculating sprayer in action. “The main purpose of a recycling sprayer is to capture and recover what

28 VINE MAGAZINE

wasn’t deposited on canes (early in the season) or on canopy later in the season, and then filter it and return it to tank for re-use,” said Cam Clifford.

extension team member, about the

Cam is the managing director of AME Group, who manufacture recycling sprayers available for use on Australian table grape vineyards.

growers.

“The ‘revolving vortex’ of air produced by the FMR recycling sprayer creates an air curtain at the front and back of the recovery shroud, which not only strongly assists the recapture, but also reduces off-target drift,” Cam said.

a conventional sprayer,” she said.

“At the start of the season, this means huge chemical savings. Recycling rates can be up to 70 per cent early season. As foliage density increases, recovery rates obviously diminish, to below 10 per cent, as expected. You can still expect an average of 30 per cent chemical savings across the season.” “In a wide table grape trellis the shrouds are obviously quite widely spaced, which does impact on the potential recapture efficiency,” weighed in Alison MacGregor, ATGA

impact of a recirculating unit. Alison has had a career-long interest in optimising spray applications for “Any spray that doesn’t land on the canopy is wasted. In spring it is hard to avoid a lot of wastage using “Recirculating units can reduce that wastage significantly.” Both Alison and Cam agree the benefits are substantial. The advantages go beyond minimising drift and chemical waste – recapturing overspray means that you get across more rows before you empty the tank, saving on not only chemical product, but re-fill time, tractor operation and labour costs. “The recycling sprayer also enables enhanced spray window opportunity due to the ability to continue spraying in wind conditions, when conventional sprayers would need to stop due to drift,” Cam said.

TECHNOLOGY

Alison said that current recirculating

“But a controller doesn’t tell you

sprayer service agents in New Zealand

vineyard sprayers had shrouds that

whether individual nozzles are blocked

and would be great to see in Australia.”

hang over the row, which was suitable

or damaged, or are appropriately

for most table grape trellises. An

oriented to hit the target.

over-row design would not be suited to linked trellises common in Western Australia, however.

Using the tools in your toolbox Whether you have the latest model sprayer or an old traditional sprayer,

added that it was important to check

“So, assessing nozzle outputs still remains an important part of sprayer and spray coverage optimisation.”

pressures in different sections of the

six or eight nozzles per side, used to be

sprayer,” he said. “Another way to check

a relatively quick and easy process.

output of different boom sections is

nozzles are under-performing, and

any sprayer.

calculate total output per hectare,”

tractor cab? ” with “No need! My sprayer tells me how much I applied!” So why do sprayer and nozzle manufacturers still recommend that

output from each boom separately. “Differences of more than 5 per cent in output or pressure between

modern sprayer can involve testing

sections indicate a plumbing fault or

more than 90 nozzles”.

obstruction that you should identify

David Manktelow, a spraying expert

and fix.

based in New Zealand, insists that

“Once you have checked nozzle outputs

“spray nozzles are precision parts”.

and checked for differences between

sprayer?

servicing and occasional replacement

the total output per distance travelled

in manual mode while you measure

approach now, because calibrating a

David said spray nozzles required

Alison. “A spray controller regulates

to operate the electronic controller

she said. “It’s much harder to use that

you check nozzles and calibrate your “Their reason is simple,” according to

adaptor that fits onto the nozzle body to test for differences in operating

coverage and operational efficiency of

if the sprayer has a controller in the

“Use a simple pressure gauge with an

traditional airblast sprayer, with only

“You could quickly identify if any

“Do I still need to calibrate nozzles

pressure in the booms or manifolds.

Alison said that calibrating a

there is a lot you can do to optimise the

Growers might respond to the question

As well as checking nozzles, David

and it was sensible to remove and clean

boom sections you can trust your rate controller or monitor to reliably deliver your target application volume.” v

all nozzles on a sprayer at least once per season.

– brilliant for maintaining output if

“While nozzles are off the sprayer, you

your travel speed varies. It also keeps

have an ideal opportunity to also check

track of total amounts applied, for your

nozzle outputs on a simple test rig,”

spray diary.

David said. “This service is offered by

HERE IS A PRE-SEASON OR WET-DAY MAINTENANCE JOB TO MAKE THE SEASON RUN SMOOTHLY STEPS

TIME-SAVER TIPS Remove and soak all nozzles and filters in tank cleaner

1

or detergent.

A portable ultrasonic cleaner (available for $100-

Remove gunk gently with a soft brush or with

cleaning nozzles

compressed air.

2

$400, designed to wash jewellery) is ideal for

Test flow (L/min) of each nozzle to make sure there are

Ask your local sprayer dealer to set up a benchtop flow

no blockages or nozzle wear. Output should be within

metre to test all your nozzles before you

10% of the specs.

reinstall them.

Operate the electronic controller in manual mode, at 3

Check outputs of different boom sections.

a constant pressure, and run each boom separately to find differences in output (L/min) between sections.

4

Check different sections of the sprayer for differences in operating pressures across the sprayer.

Use a simple pressure gauge with an adaptor that fits onto the nozzle body to check pressure in that section. Repeat on each manifold or boom.

VINE MAGAZINE 29

BIOSECURITY

Levy to protect dried grape industry Dried Fruits Australia continues to work with Plant Health Australia on several plant disease and pest threats which impact dried grapes, along with other horticultural industry sectors.

Australia’s dried grape industry, while

Additionally, because we are in an

estimated to be worth $40 million

inland temperate zone and an array

in farm gate value, is only a small

of horticultural produce is grown and

horticultural sector.

marketed from the region, there is

A pest or disease outbreak would have serious implications for

an increased risk of incursions from pests and diseases.

Australian dried grape production

For these reasons, the statutory levy

and every producer would be severely

of $1/tonne will be used specifically

affected.

for biosecurity purposes under the auspice of Plant Health Australia

DFA is immediately notified of any

Emergency pest responses involve

potential incursion as a signatory to

state and federal governments as well

the Emergency Plant Pest Response

as all the horticultural/agricultural

Deed (EPPRD).

industries that could be impacted by

To date, the levy has raised $11,000.

the pest or disease issue.

A protocol is in place with Plant

From the beginning of 2021, the new Dried Grape Biosecurity Levy of $1/

Costs involved in eradication are then

tonne came into effect.

shared between governments and

This statutory levy was voted on

industry bodies.

and is collected by the Federal Department of Agriculture.

Health Australia so that this funding can be used for expenditure incurred by the dried grape industry in relation to emergency plant pest response

by growers in 2019 and assists in

Unfortunately, the threat of

costs.

contributing to timely and effective

emergency pest and disease

responses in emergency plant pest

outbreaks grows exponentially

If there are any questions on the levy,

situations.

each year.

It can also be used for education and

This is evidenced by incursions at

training on biosecurity measures for

Australian ports and across growing

all involved in dried grape production.

regions.

30 VINE MAGAZINE

please contact the DFA office on (03) 5023 5174. v Below: A late instar of a brown marmorated stick bug with characteristic white bands on the antennae, legs and the outer edge of the abdomen. Image courtesy bugwood.org

BIOSECURITY

Spot the difference MEDI T E RRA N E A N F RUI T F LY V S Q U EEN S L A N D F R U I T F LY

Report anything unusual in your

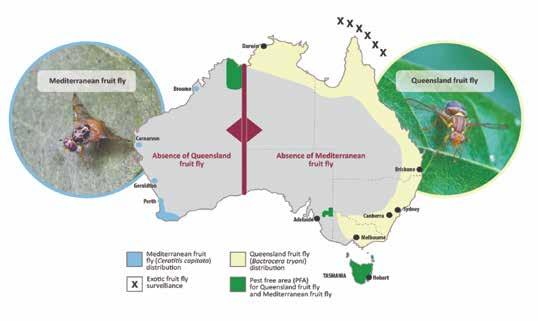

There are two main species of fruit flies threatening Australia's $13 billion horticultural industry: the Queensland fruit fly (Bactrocera tryoni) and the Mediterranean fruit fly (Ceratitis capitata).

backyard or on your farm by calling

feeding and jump out from produce,

the Exotic Plant Pest Hotline on 1800

burrowing into the ground and

084 881.

changing into brown, barrel-shaped

Breaking the life cycle of Qfly or Medfly

pupae.

- Both Qfly and Medfly can lay hundreds of eggs during their lifespan.

Queensland fruit fly (Qfly) occurs in

- When fully grown, larvae stop

- Adult Qfly and Medfly will develop inside the pupae and emerge from the ground, ready to breed. - I nfested fruit or vegetables that fall to the ground allow the life cycle to

- Multiple generations can occur in a

the Northern Territory, Queensland, New South Wales and Victoria and is

year, when temperature and humidity

endemic to Australia. Mediterranean

conditions are ideal.

fruit fly (Medfly) is an introduced

- The female of both pierces (stings)

pest and is only present in Western

maturing fruit and lays eggs just

Australia, mostly in the south-west of

below the surface.

the state.

continue. v Sources: National Fruit Fly Council; Plant Health Australia; Department of Agriculture, Fisheries and Forestry

- Eggs hatch after two to three

However, growers must remain vigilant

days and the creamy-white larvae

for any incursions of Medfly from west

(maggots) start developing.

to east, or Qfly from east to west.

Q F LY - Distinct yellow markings on the sideas and back

DISTRIBUTION OF FRUIT FLY IN AUSTRALIA

- Larvae (maggots) are creamy white and about 5-10mm long - Adults are up to 8mm long - Elongated redish brown body - Transparent wings

M E D F LY - Adults are 3-5mm long - Light brown body with numerous black areas in a characteristic pattern. - Mottled transparent wings with distinctive brown bands - Larvae (maggots) are creamy white and about 7-8mm long

VINE MAGAZINE 31

BIOSECURITY