Professional Documents

Culture Documents

Investigating The Reliability of Selected

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Investigating The Reliability of Selected

Copyright:

Available Formats

Volume 5, Issue 3, March – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Investigating the Reliability of Selected

Mix Design Methods for the Production of

Super-Workable Concrete

Kemejika I. Amadi-Oparaeli1, Ichebadu G. Amadi2 and Enwuso A. Igwe3

1,2,3

Department of Civil Engineering

Rivers State University, Port Harcourt, Nigeria

Abstract:- In order to proffer solution to the difficulties Irrespective of the attractive qualities of SCC, one

experienced in achieving a super-workable concrete major drawback of super-workable concrete is its cost of

commonly known as Self Compacting Concrete, four production which relates to the use of high quantity of

mixture design methods were carefully selected and Portland cement. An option to bring down the production

investigated. Three mixes were designed for each cost of super-workable concrete is to bring in mineral

method considered in accordance with their admixtures like fly ash as partial replacement for cement

specifications. The methods considered are: the (Uysal and Sumer 2011). Secondly, it is considered

American Concrete Institute, EFNARC, European challenging to design because of the need to balance the

Project Group and the Optimal Mixture Design (Yu et characteristics of its fresh properties (Sedran and de Larrard

al) methods. The results disclosed that the EFNARC 1999). Numerous efforts have been made to develop an

method is the most reliable method in the production of optimized mixture design method for super-workable

super-workable concrete as it significantly satisfies the concrete, however, no specific mixture design method has

fresh properties of the concrete. been successfully developed to meet all fresh concrete

criteria (Grdic, Despotovic and Toplicic-Curcic, 2008;

Keywords:- Mix Design Methods, Super-Workable BIBM et al. 2005). This study will seek to investigate the

Concrete and Fresh Properties. reliability of different mix design methods to produce SCC.

I. INTRODUCTION II. EXPERIMENTAL PROGRAM

Super-workable concrete commonly called Self- Materials

Compacting Concrete (SCC) was first discovered in Japan Cement: Hanson Heidelberg Portland cement product

since 1988. Its discovery was a landmark achievement in (CEM I 52,5N) with density of 3029 kg/m3 and in

concrete construction which helped to solve the problem of conforming to BS EN 197-1 was used.

inadequate compaction leading to durability issues of

concrete structures. Also, SCC was a solution to the Aggregate: Fine aggregate obtained within Coventry,

diminishing number of skilled workers which was quite United Kingdom with grain size not greater than 4.75 mm

expensive too (Okamura and Ouchi 2003; Goodier, 2003). and having density of 2670 kg/m3 was used. The coarse

aggregate has grain size not greater than 19 mm and a

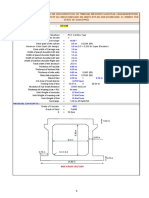

SCC also referred to as Self-Consolidating, Self- density of 2525 kg/m3. The particle size distribution graphs

Placing or Self-Leveling Concrete (ACI 2007) is a special can be seen in figure 1.

type of concrete which can flow into form-work corners

and reinforcement gaps only by its self-weight without the Fly ash: Pulverized fuel ash produced in Scotland and

need for external compaction or mechanical vibration, conforming to BS EN ISO 9002:1994, with a density of

whilst recording minimal bleeding and segregation (Umar 2090 kg/m3 was used.

and Al-Tamimi 2011; Su, Hsu and Chai, 2001).

Super-plasticizer: A poly-carboxylate polymer based

The most appealing attributes of Super-workable super-plasticizer (ADVA flow 411) from Grace

concrete are those of its fresh properties, which has to do Construction and in conformity with EN 934-2 and having

with the passing and filling abilities, and the resistance to a recommended dosage of 600 ml- 1200 ml/ 100 kg of

segregation, which leads to health, economic, technological cement was used.

and aesthetic advantages in terms of noise reduction, cost

of labour and smooth finishes (ACI 2007). Methods

The experiment consists of preparing mixture designs

in line with the standards considered in this study as shown

in Table 1. About 30 litres of concrete was mixed in

accordance with the selected methods to accommodate all

relevant tests.

IJISRT20MAR658 www.ijisrt.com 1245

Volume 5, Issue 3, March – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

MIX CEMENT ADMIXTURE WATER FINE COARSE HRWRA w/p REMARK

DESIGN AGGRE. AGGR.

METHODS

EFNARC 160-240 ltrs (400 - 600 Max. Rest of mix volume 28 – 0.8 – Self-compatibility

(2002) kg/m3) 200kg/m3 35% by 1.1 by is achieved by trial

vol. vol. mixes

YU et al 30 – 40% of powder - Sand ≤ 33% of ˃0.5% ≤ 0.4 -

(2005) mortar ≤ mix vol. of

0.44 by cement

vol. s/a =

45-50%

BIBM et al 380 – 600 kg/m3 150 – 48 – 55% 750 – - 0.85 – Self-compatibility

(2005) 210 of total 1000kg/m3 1.1 is achievd by trial

kg/m3 aggr. wgt. mixes

ACI (2007) Powder =386 – 457kg/m3; Mortar = 68 – 72% of mix; 28 – 32% - 0.32 – Self-compatibility

Paste =34 – 40% of mix of mix 0.45 by is achieved by trial

vol. mass mix

Table 1:- Mix design methods considered

Fig 1:- Sieve analysis of aggregates

Concrete mix proportions

The mix ratios for the concrete are shown in Table 2. All concrete mix were prepared in accordance with the specifications

of the mix design methods considered.

MIX DESIGN CEMENT PFA POWDER FINE COARSE WATER SP(k W/P w/p

ID (kg) (kg) (kg) (kg) (kg) (kg) g) (mass) (vol.)

EFNARC (2002)

EFN-M1-40P 330 220 550 850 750 175 7.8 0.32 0.82

EFN-M2-40P 340 240 600 760 750 200 4.6 0.33 0.85

EFN-M3-40P 300 200 500 840 820 158 6.8 0.32 0.81

YU et al (2005)

YU-M1-40P 330 220 580 785 785 165 6.4 0.3

YU-M2-40P 300 200 500 780 790 180 4.4 0.36

YU-M3-40P 300 200 500 790 820 175 5.2 0.35

EUROPEAN PROJECT GROUP (BIBM et al 2005)

BIB-M1-40P 330 220 550 764 788 190 5 0.89

BIB-M2-40P 348 232 520 790 775 175 7.2 0.87

BIB-M3-40P 270 180 450 870 800 172 7.2 0.98

AMERICAN CONCRETE INSTITUTE (ACI 2007)

ACI-M1-40P 280 187 467 890 740 155 9.2 0.33

ACI-M2-40P 285 190 475 840 745 185 7.2 0.31

ACI-M3-40P 276 184 460 895 780 161 8.4 0.35

EFN-M1-40P represents 1st mix for EFNARC method with 40% PFA, YU-M2-40P represents 2nd mix for Yu et al method

with 40% PFA, BIB-M3-40P represents 3rd mix for BIBM et al method with 40% PFA and similar to all other mix identities

Table 2:- Concrete mixture proportions for various methods

IJISRT20MAR658 www.ijisrt.com 1246

Volume 5, Issue 3, March – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Tests

The tests carried out are only those relating to the fresh properties which include: Visual Stability Index (VSI), Slump-flow

and T500, V-funnel and L-box tests. These tests were conducted in quick pace as soon as the concrete mixture was ready. The

slump-flow and T500 tests were conducted together, then the V-funnel test preceded the L-box test (Testing SCC 2005). The VSI

test was carried out immediately after the slump flow test using the eye to observe the presence of mortar halos and patty. This is

intended to physically confirm the extent of stability of the concrete mixture. The rating for this test is as shown in Table 3.

Table 3:- Visual Stability Index (VSI) rating for SCC (PCI 2003:30)

T500 and slump flow tests measures the flow rate and flow ability of super-workable concrete in the absence of obstacles.

The tests were conducted in compliance with the EFNARC specification, which is in agreement with BS EN 12350-8:2010. The

recommended ranges for a good filling ability are: 2-5secs for T500 and 650mm-800mm for slump flow. The pictorial view of the

test is shown in Plate 1.

V-funnel test measures viscosity and filling ability of super-workable concrete. It was conducted in compliance with BS EN

12350-8:2010. Plate 2 shows the pictorial view of the test.

L-box text measures the passing ability of super-workable concrete. It was conducted in conformity with BS EN 12350-

8:2010. The ratio of the difference in height of the vertical section (H1) and that of the horizontal section (H2) was taken as the L-

box reading (see Plate 3).

Plate 1: Slump-flow test.

Plate 2: V-funnel test

IJISRT20MAR658 www.ijisrt.com 1247

Volume 5, Issue 3, March – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Plate 3: L-box test

III. RESULTS

Table 4 shows the results of tests carried out to investigate the fresh properties of super-workable concrete for the mixture

design methods considered. The results are graphically displayed in Figures 2, 3, 4, and 5.

Mix design ID Slump flow (mm) t500 (s) V-funnel (s) L-box (H1/H2) VSI

EFNARC (2002)

EFN-M1-40P 690 2.3 6.6 0.82 0

EFN-M2-40P 720 1.82 5.4 0.92 2

EFN-M3-40P 660 4.65 10.3 0.83 0

Yu et al (2005)

YU-M1-40P 668 2.4 6 0.81 0

YU-M2-40P 635 1.9 5.89 0.71 1

YU-M3-40P 656 3.9 6.11 0.68 0

European Project Group (BIBM et al 2005)

BIB-M1-40P 727.5 2 6.83 0.9 1

BIB-M2-40P 668 2.3 6.89 0.82 0

BIB-M3-40P 574 2.9 5.92 0.66 0

American Concrete Institute (2007)

ACI-M1-40P 612 3.7 9.9 0.68 1

ACI-M2-40P 540 3.3 7.6 0.57 0

ACI-M3-40P 615 2.6 6.8 0.76 1

Table 4:- Test results on fresh properties of super-workable concrete.

Fig 2:- Slump-flow results for the different methods

IJISRT20MAR658 www.ijisrt.com 1248

Volume 5, Issue 3, March – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Fig 3:- T500 results for the different methods

Fig 4:- V-funnel results for the different methods

Fig 5:- L-box results for the different methods

IJISRT20MAR658 www.ijisrt.com 1249

Volume 5, Issue 3, March – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

IV. DISCUSSIONS workable concrete produced with this method is more of

the VMA type.

EFNARC (2002)

Figure 2 shows that all concrete mixtures produced A careful observation of Tables 1 and 4 shows that the

using the EFNARC method achieved a slump-flow within entire mixes designed with powder content less than 480

the standard range; this simply tells that the concrete has a kg/m3 resulted in low slump value.

good filling ability. Also, the V-funnel and T500 results

showed in Figures 3 and 4, falls within the specified range V. CONCLUSIONS

except for mix EFN-M2-40P which reveals slight

segregation, which may be as a result of no VMA in the The following are the conclusions drawn from this

mixture. Figure 5 shows that the L-box results are within study:

the target range, thus indicating a satisfactory passing The EFNARC mixture design method satisfies all fresh

ability. From Table 4, the VSI rating shows 0 and 1, which properties of Super-workable concrete, and it is flexible

is an indication of good stability, except for mix EFN-M2- and adequate for SCC production.

40P which had slight segregation. Generally, it can be The mixture design method proposed by BIBM et al

inferred that the EFNARC method is adequate for the satisfies all fresh properties of super-workable concrete,

design of super-workable concrete. but is more convenient for the production of the

combined type concrete, depending on the material

Optimal mixture design (Yu et al. 2005) properties.

Figures 2, 3 and 4 showed that all concrete mixtures To achieve a good passing ability of a super-workable

produced with this method are within the target range for concrete using the Yu et al mixture design method, it is

slump-flow, T500 and V-funnel, apart from the mixture advisable to adopt equal percentage of fine and coarse

tagged YU-M2-40P which had a low slump-flow, T500 and aggregates in the mix.

V-funnel values. This can be linked to the low dosage of The ACI mixture design is difficult to achieve because

super-plasticizer recommended by this method. The of the low paste content recommend by the method.

mixtures within the target ranges signify good filling Hence, it is deemed not suitable for massive concrete

ability. From Figure 5, the second and third mixtures fall work.

outside the specified range, indicating poor passing ability;

this can be ascribed to the high coarse to total aggregate In summary, it can therefore be concluded that the

ratio proposed by this method. From Table 4, VSI test was EFNARC mixture design method is the most suitable in the

satisfied for all mixes. production of super-workable concrete.

European Project Group (BIBM et al. 2005). REFERENCES

From Figure 2, 3, 4 and 5, the first two mixtures fall

within the target ranges as they show good filling and [1]. ACI 237R-07 (American Concrete Institute) (2007)

passing abilities. The third mix (BIB-M3-40P) only Self-Consolidating Concrete, Farmingthon Hills,

satisfied the T500 test, implying a good viscosity however [online] available from

the filling and passing ability is poor. This could be a <http://www.scribd.com/doc/59020140/ACI-237R-

consequence of low powder content or insufficient 07-Self-Consolidating-Concrete-1> [2 July 2011], 15-

proportioning of super-plasticizer and VMA dosages in the 18.

mix. From Table 4, VSI test was satisfied for all mixes. The [2]. ASTM D422 – 63 (2007) “Standard Test Method for

results also reveal that this method can be suitable for both Particle-Size Analysis of Soils”.

the powder and combined types of super-workable [3]. BIBM., CEMBUREAU., EFCA., EFNARC.,

concrete, but not too suitable for the VMA type. Although, ERMCO. (Self-Compacting Concrete European

the reduced range for water-powder ratio proposed by this Project Group) (2005) The European Guidelines for

method, compared to that of EFNARC method, makes it a Self-Compacting Concrete Specification, Production

little stressful to develop a mix design for the powder type and Use [online] available from

super-workable concrete which requires very low water- <http://www.efnarc.org> [1 June 2011]

powder ratio. [4]. BS EN 12350-8: 2010 ‘Testing fresh concrete’. Part

8: self-compacting concrete – slump-flow test.

American Concrete Institute (2007) [5]. EFNARC (European Federation of Specialist

Figures 2, 3 and 4 reveals an unsatisfactory slump- Construction Chemicals and Concrete Systems)

flow but high T500 and V-funnel values. This indicates poor (2002) Specification & Guidelines for Self-

filling ability, but a highly viscous SCC mixture. This could Compacting Concrete [online] available from <

be due to insufficient super-plasticizer dosage. From Figure http://www.efnarc.org > [30 May 2011]

5, it is seen that all mixes are below the target range, which [6]. EFNARC (2006) 'Guidelines for viscosity modifying

is indicative of poor passing ability. This may also be admixtures for concrete' [online] available from

attributed to an insufficient super-plasticizer dosage. Table <http://www.efca.info/dowmloads/GuidelinesforVMA

4 reveals a satisfactory VSI results for this method. The (document 180).pdf> [24 July 2011]

range of powder content proposed by this method, when [7]. Goodier, C.I. (2003) 'Development of self-compacting

compared to EFNARC‟s classifications shows that super- concrete'. Structures and Buildings 156, 405-414

IJISRT20MAR658 www.ijisrt.com 1250

Volume 5, Issue 3, March – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

[8]. Grace Construction Product (n.d) Concrete Product

Guide, Products for Improving Concrete

Performances [online] available from

<http://www.uk.graceconstruction.com> [29 June

2019]

[9]. Grdic, Z., Despotovic, I. and Toplicic-Curcic, G.

(2008) ‘Properties of self-compacting concrete with

different types of additives’, Facta universitatis -

series: Architecture and Civil Engineering. National

Library of Serbia, 6(2), 173–177

[10]. Su, N., Hsu, K. C. and Chai, H. W. (2001) ‘A simple

mix design method for self-compacting concrete’,

Cement and Concrete Research. Pergamon, 31(12),

1799–1807

[11]. Okamura, H. and Ouchi, M. (2003) 'Self-Compacting

Concrete'. Journal of Advanced Concrete Technology,

Japan Concrete Institute 1, 5-15

[12]. Sedran, T. and de Larrard, F. (1999) 'Optimization of

self-compacting concrete thanks to packing model' in

PRO 42: 1st International RILEM symposium on self-

compacting concrete ed. by Skarendahl, A. and

Peterson, O.

[13]. Testing SCC (2005) 'Guidelines for testing fresh self-

compacting concrete'. European research project:

measurement of properties of fresh self-compacting

concrete.

[14]. Umar, A. and Al Tamimi, A. (2011) 'Influence of

Viscosity Modifying Admixture (VMA) on the

Properties of SCC Produced Using Locally Supplied

Materials in Bahrain'. Jordan Journal of Civil

Engineering 5, 32-49

[15]. Uysal, M. and Sumer, M. (2011) 'Performance of self-

compacting concrete containing different mineral

admixtures'. Construction and building materials 25,

4112-4120

[16]. Yu, Z., Pan, Z., Liu, X. and Liu, Z. (2005) 'Optimal

Mixture Design of High Performance Seslf-

Compacting Concrete'. In PRO 42: 1st International

Symposium on Design, Performance and use of Self-

Consolidating concrete 26-28 May 2005 ed. by Yu,

Z., Shi, C. and Khayat, K.H. Changsha, Husan, China

181-190

IJISRT20MAR658 www.ijisrt.com 1251

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Lake Dunlap Dam 2018 InspectionDocument30 pagesLake Dunlap Dam 2018 InspectionAnonymous ys3YM79m8100% (2)

- Udoeyo Structural AnalysisDocument391 pagesUdoeyo Structural Analysisjucar fernandez100% (4)

- Pressure Vessel Handbook - 10th Edition by E Megyesy-4 PDFDocument53 pagesPressure Vessel Handbook - 10th Edition by E Megyesy-4 PDFVanderson RezendeNo ratings yet

- Formulation and Evaluation of Poly Herbal Body ScrubDocument6 pagesFormulation and Evaluation of Poly Herbal Body ScrubInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Comparatively Design and Analyze Elevated Rectangular Water Reservoir with and without Bracing for Different Stagging HeightDocument4 pagesComparatively Design and Analyze Elevated Rectangular Water Reservoir with and without Bracing for Different Stagging HeightInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Explorning the Role of Machine Learning in Enhancing Cloud SecurityDocument5 pagesExplorning the Role of Machine Learning in Enhancing Cloud SecurityInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Review: Pink Eye Outbreak in IndiaDocument3 pagesA Review: Pink Eye Outbreak in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design, Development and Evaluation of Methi-Shikakai Herbal ShampooDocument8 pagesDesign, Development and Evaluation of Methi-Shikakai Herbal ShampooInternational Journal of Innovative Science and Research Technology100% (3)

- Studying the Situation and Proposing Some Basic Solutions to Improve Psychological Harmony Between Managerial Staff and Students of Medical Universities in Hanoi AreaDocument5 pagesStudying the Situation and Proposing Some Basic Solutions to Improve Psychological Harmony Between Managerial Staff and Students of Medical Universities in Hanoi AreaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Survey of the Plastic Waste used in Paving BlocksDocument4 pagesA Survey of the Plastic Waste used in Paving BlocksInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Electro-Optics Properties of Intact Cocoa Beans based on Near Infrared TechnologyDocument7 pagesElectro-Optics Properties of Intact Cocoa Beans based on Near Infrared TechnologyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Auto Encoder Driven Hybrid Pipelines for Image Deblurring using NAFNETDocument6 pagesAuto Encoder Driven Hybrid Pipelines for Image Deblurring using NAFNETInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Cyberbullying: Legal and Ethical Implications, Challenges and Opportunities for Policy DevelopmentDocument7 pagesCyberbullying: Legal and Ethical Implications, Challenges and Opportunities for Policy DevelopmentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Navigating Digitalization: AHP Insights for SMEs' Strategic TransformationDocument11 pagesNavigating Digitalization: AHP Insights for SMEs' Strategic TransformationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Hepatic Portovenous Gas in a Young MaleDocument2 pagesHepatic Portovenous Gas in a Young MaleInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Review of Biomechanics in Footwear Design and Development: An Exploration of Key Concepts and InnovationsDocument5 pagesReview of Biomechanics in Footwear Design and Development: An Exploration of Key Concepts and InnovationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Automatic Power Factor ControllerDocument4 pagesAutomatic Power Factor ControllerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Formation of New Technology in Automated Highway System in Peripheral HighwayDocument6 pagesFormation of New Technology in Automated Highway System in Peripheral HighwayInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Drug Dosage Control System Using Reinforcement LearningDocument8 pagesDrug Dosage Control System Using Reinforcement LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Effect of Time Variables as Predictors of Senior Secondary School Students' Mathematical Performance Department of Mathematics Education Freetown PolytechnicDocument7 pagesThe Effect of Time Variables as Predictors of Senior Secondary School Students' Mathematical Performance Department of Mathematics Education Freetown PolytechnicInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mobile Distractions among Adolescents: Impact on Learning in the Aftermath of COVID-19 in IndiaDocument2 pagesMobile Distractions among Adolescents: Impact on Learning in the Aftermath of COVID-19 in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Securing Document Exchange with Blockchain Technology: A New Paradigm for Information SharingDocument4 pagesSecuring Document Exchange with Blockchain Technology: A New Paradigm for Information SharingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Perceived Impact of Active Pedagogy in Medical Students' Learning at the Faculty of Medicine and Pharmacy of CasablancaDocument5 pagesPerceived Impact of Active Pedagogy in Medical Students' Learning at the Faculty of Medicine and Pharmacy of CasablancaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Intelligent Engines: Revolutionizing Manufacturing and Supply Chains with AIDocument14 pagesIntelligent Engines: Revolutionizing Manufacturing and Supply Chains with AIInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Enhancing the Strength of Concrete by Using Human Hairs as a FiberDocument3 pagesEnhancing the Strength of Concrete by Using Human Hairs as a FiberInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Exploring the Clinical Characteristics, Chromosomal Analysis, and Emotional and Social Considerations in Parents of Children with Down SyndromeDocument8 pagesExploring the Clinical Characteristics, Chromosomal Analysis, and Emotional and Social Considerations in Parents of Children with Down SyndromeInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Supply Chain 5.0: A Comprehensive Literature Review on Implications, Applications and ChallengesDocument11 pagesSupply Chain 5.0: A Comprehensive Literature Review on Implications, Applications and ChallengesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Teachers' Perceptions about Distributed Leadership Practices in South Asia: A Case Study on Academic Activities in Government Colleges of BangladeshDocument7 pagesTeachers' Perceptions about Distributed Leadership Practices in South Asia: A Case Study on Academic Activities in Government Colleges of BangladeshInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Advancing Opthalmic Diagnostics: U-Net for Retinal Blood Vessel SegmentationDocument8 pagesAdvancing Opthalmic Diagnostics: U-Net for Retinal Blood Vessel SegmentationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Making of Self-Disposing Contactless Motion-Activated Trash Bin Using Ultrasonic SensorsDocument7 pagesThe Making of Self-Disposing Contactless Motion-Activated Trash Bin Using Ultrasonic SensorsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Natural Peel-Off Mask Formulation and EvaluationDocument6 pagesNatural Peel-Off Mask Formulation and EvaluationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Beyond Shelters: A Gendered Approach to Disaster Preparedness and Resilience in Urban CentersDocument6 pagesBeyond Shelters: A Gendered Approach to Disaster Preparedness and Resilience in Urban CentersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Handling Disruptive Behaviors of Students in San Jose National High SchoolDocument5 pagesHandling Disruptive Behaviors of Students in San Jose National High SchoolInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- MJCS Presentation RDocument32 pagesMJCS Presentation RenvironmentalhabitatNo ratings yet

- Chapter 6 BricksDocument56 pagesChapter 6 BricksDdeqz Elina Bueno I100% (1)

- HKU2023 4. Notable Tunnel Failure Case HistoriesDocument86 pagesHKU2023 4. Notable Tunnel Failure Case HistoriesYH NaismithNo ratings yet

- Detailed Estimation Report - High Rise at GurgaonDocument15 pagesDetailed Estimation Report - High Rise at GurgaonJackson ChristianNo ratings yet

- RCC Box Culvert DesignDocument27 pagesRCC Box Culvert DesignPraveen Cyssan0% (1)

- Design of Spill Through Abutment FoundationDocument42 pagesDesign of Spill Through Abutment Foundationinfra120No ratings yet

- Prestressed Concrete - (Part 8) - 1Document12 pagesPrestressed Concrete - (Part 8) - 1Christopher NazarenoNo ratings yet

- Buckling and Ultimate Loads For Plate Girder Web Plates Under Edge Loading ... (Pdfdrive)Document100 pagesBuckling and Ultimate Loads For Plate Girder Web Plates Under Edge Loading ... (Pdfdrive)Dawid GabrysiakNo ratings yet

- Flow over rectangular sharp-crested weirsDocument7 pagesFlow over rectangular sharp-crested weirsmasteringmastering123No ratings yet

- Construction of A 3 Bedroom BungalowDocument13 pagesConstruction of A 3 Bedroom BungalowElujekwute Benjamin100% (1)

- Cavitation Analysis of Kaplan Series Propeller Effect of Pitch Ratio and Nprop Using CFDDocument11 pagesCavitation Analysis of Kaplan Series Propeller Effect of Pitch Ratio and Nprop Using CFDAgung BosqueNo ratings yet

- Intro To IRDocument14 pagesIntro To IRsukanya.vNo ratings yet

- Topographic Map Symbols GuideDocument1 pageTopographic Map Symbols GuideRonaldo Jr. DIAZ100% (1)

- 2020 - MIDAS - Lite VersionDocument1 page2020 - MIDAS - Lite VersionniteshNo ratings yet

- Equal Friction MethodDocument7 pagesEqual Friction MethodfghabboonNo ratings yet

- Advance Montessori Education Center of Isabela, Inc.: Tle 8 Learner'S Module 5 Second QuarterDocument11 pagesAdvance Montessori Education Center of Isabela, Inc.: Tle 8 Learner'S Module 5 Second QuarterPrincess Guiyab0% (1)

- Es Iso - 1452-3 - 2015 (E)Document41 pagesEs Iso - 1452-3 - 2015 (E)Chalew GebruNo ratings yet

- T11-Conveyance Structures (Inverted Syphon)Document7 pagesT11-Conveyance Structures (Inverted Syphon)hassan alzaidyNo ratings yet

- Finite Element Fatigue Analysis of Unsupported CraDocument9 pagesFinite Element Fatigue Analysis of Unsupported CraCarlos CarvNo ratings yet

- BlowerDocument7 pagesBlowerghanshyam29998987100% (2)

- Beam Tutorial 1 Worked SolutionDocument8 pagesBeam Tutorial 1 Worked SolutionMeyer EdouardNo ratings yet

- 3 Codified Requirements For MORE THAN 2 LPG CYLINDERDocument5 pages3 Codified Requirements For MORE THAN 2 LPG CYLINDERMrigank AggarwalNo ratings yet

- Lecture Notes-1 - Physical and Mechanical Properties of Materials-2020Document11 pagesLecture Notes-1 - Physical and Mechanical Properties of Materials-2020Jesh KeerawellaNo ratings yet

- Drip Legs Definition Purpose Configuration Selection Installation and Sizing PDFDocument4 pagesDrip Legs Definition Purpose Configuration Selection Installation and Sizing PDFFaizal KhanNo ratings yet

- Design of Concrete Structures - Lesson 1 IntroductionDocument11 pagesDesign of Concrete Structures - Lesson 1 IntroductionSHAHRIER NAZIM SHUVRONo ratings yet

- Introduction to Plain and Reinforced Concrete DesignDocument24 pagesIntroduction to Plain and Reinforced Concrete Designhira maqsood100% (1)

- Causes of Cracks in RCC SlabsDocument4 pagesCauses of Cracks in RCC SlabsNidDouNo ratings yet