5 tips for piecing your quilt backing fabric

We all LOVE backing fabrics that are 108” wide or more. They are especially easy to use on a longarm machine and eliminate many headaches, but sometimes you just have to have that special fabric that will need to be pieced together so it is big enough to use for the back of your quilt.

There are five things to keep in mind when piecing your backing fabric. These five things will prevent unwanted puckers, pleats and other nasty problems from invading your quilt back. The tips apply to both sit-down and stand-up machines but are especially helpful for a longarm machine like our APQS family of machines.

Prep the edge of the fabric

It is important to load fabric to a longarm frame so it is square. When the fabric is loaded along its grain line, it will prevent a saggy back from trapping fullness as you work which results in pleats in the back of your quilt. To be sure you are piecing your backing fabric square, you’ll snip and rip along the fabric to reveal the true grain of the fabric.

Once you have ripped the fabric along the true grain, you’ll use that ripped edge to align the pieces of backing fabric together. By lining up the two ripped edges of the fabric together, you’ll be sure your new seam for your backing fabric is straight and true, which will result in a square quilt at the end!

Consider the size of the seam and the stitch

Increase the size of the seam you use to piece your back. Normally I love a quarter inch seam for most everything, but for a backing fabric, I’ll use about a 3/4” seam. Don’t forget that the seam for your backing fabric is quite long, and you’ll be putting it under a great deal of stress as you pull on one end of your quilt (and that seam) to snuggle with it on the couch. It is important to give a bit more fabric for the seam to anchor in when piecing your backing fabric.

When I am piecing a seam, I like to use about a 2.5 stich length on my domestic sewing machine. However, for a backing fabric that is too loose. Lower your stitch length down to about 1.5. This will strengthen the seam so it will put up with being pulled along that long seam line over time.

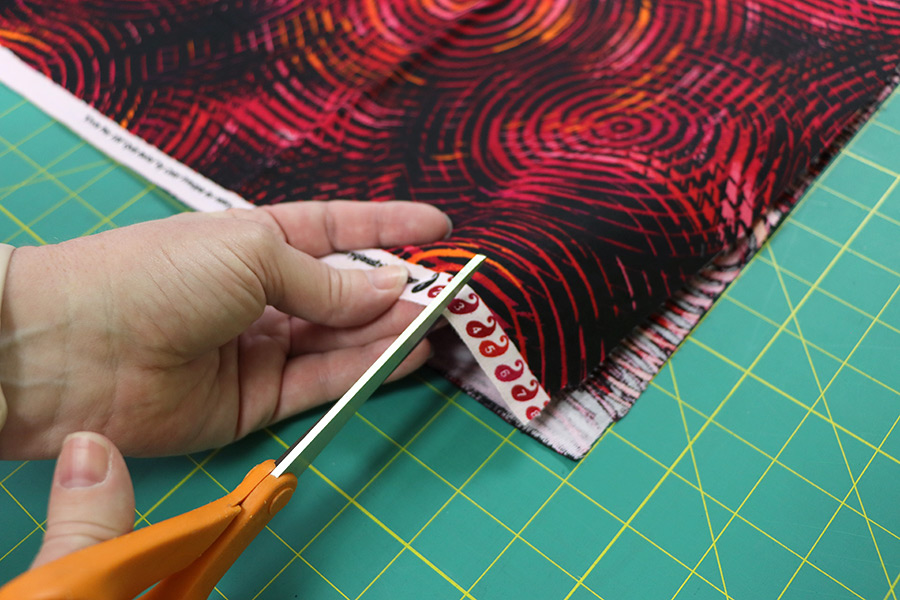

Remove the selvedges

The selvages of fabric are the end pieces where you’ll find the name of the fabric printed along with the designer and, generally, the color dots showing all the colors used to make the fabric. The downside is that these selvedges are more tightly woven than the rest of the cotton, so it will shrink at a different rate.

Remove the selvages when piecing your back and you’ll prevent the seam from looking puckered after that first wash. If you are given a back to use with the selvedges intact, a small relief cut along the selvage every three inches or so will help prevent as many puckers as possible during that first wash as your cotton shrinks up a bit.

Pressing the seam

When piecing a quilt top, you’ll generally press to one side. This will give strength to the seam and some dimensionality to your quilt top. However, when piecing a backing fabric, it is best to press the seam open. In this way you’ll spread the bulk of the seam out along the pole that it gets wrapped up within. Our goal is to prevent pleats and puckers. By pressing the seam open, you can better spread out the layers so they don’t have as much of an opportunity to stack upon each other as your load your backing fabric. This will go a long way towards eliminating pleats and puckers along the backing fabric.

Orient the seam along the poles

When loading a quilt to a longarm machine you’ll be pinning two edges of the fabric to two different canvas covered poles. Your backing will be wound up on these poles tightly and evenly. To ensure the fabric rolls up onto the poles in the same way across the pole, orient any seam in the backing fabric so it runs parallel to the bars on your table frame.

If you orient the seam so it run perpendicular to the roller, you will be stacking the seam on top of itself with each roll of the pole as you load the backing fabric. As each rotation stacks yet another thickness of the fabric and seams, you’ll find it creates a bit of a mountain on the pole with little valleys to each side. This can introduce pleats into your backing fabric because the fabric is wound up evenly.

By loading a pieced backing with the seam oriented parallel to the bars, it will allow all of the bulk of the seam to get spread out along the length of the pole. This will greatly reduce bulk and the potential for pleats along the seam as you work.