Professional Documents

Culture Documents

Green Quality Improvement Using Six Sigma Method

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Green Quality Improvement Using Six Sigma Method

Copyright:

Available Formats

Volume 5, Issue 8, August – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Green Quality Improvement Using Six Sigma Method

Sutrisno Harianto Ellysa Nursanti

Master Degree Program in Industrial Engineering in Lecturer in Industrial Engineering Department, Postgraduate

National Institute Of Technology (ITN) Program National Institute of Technology (ITN)

Malang, Indonesia Malang, Indonesia

Abstract:- Traditional cast brass handicrafts Majapahit [2],[3]. Brass craft industry SMEs are required to pay

is one of the nation's cultural heritage which has a high attention to the surrounding environment in production

historical value. The uniqueness and quality become the process and produce products that are safe and consumeable

hallmark of this craft products. The results of by consumers.

handmade products such as sculptures, wall hangings,

souvenirs, ornaments doors and so on. To increase the II. DESCRIPTION SYSTEM

sales of traditional handicrafts of brass castings,

required Majapahit applicative technical efforts in The production process of making Majapahit brass cast

improving the quality of products which are eco- sculpture in Bejijong village is still traditional using simple

friendly. Quality improvement method such as Six equipment. The production system begins with the making

sigma. Six sigma focuses on decreasing flawed rate, by of the master mold and preparation of raw materials, then

reaching the standard 3, 4 flawed in a thousand the casting process is carried out, then the cooling process

possibility. Six sigma has 5 phases; define, measure, and removal of the cast sculpture from the mold, as well as

analyze, improvement, and control. In this research, six the finishing and coloring process.

sigma is applied in producing cast brass handicraft

starting from making the master mold, preparation of Green quality improvement or green quality

smelting raw materials, cooling process, releasing of the improvement is now very popular with consumers. This is

mold, and finishing. Purposefully to improve the quality shown by the greater awareness of consumers to get

by overcoming and decreasing the high of flawed products that are feasible, safe and environmentally friendly.

possibility and also applying marketing mixture in Consumers are willing to pay more for products that do not

improving the market segmentation of traditional cast damage the environment or are environmentally friendly.

brass of Majapahit market. The result is quality

improvement is shown by decreasing happen in number This change in consumer awareness results in large

of flawed product in total of mean for about 154, 8 and small industries indirectly having to pay attention to the

decreased to 59,5. While the calculation of the six sigma, environment and take responsibility not to damage the

flawed product of cast brass handicraft is for about environment. The product produced is not only feasible and

1,7625 sigma value or being in level 2 and increased to safe but in the production process it must be cleaner and

3,725 or being in level 4 with the flawed possibility in more environmentally friendly.

amount 235,000 for thousand times of production. The

ability of production for the requirement which is The biggest obstacle faced by craftsmen in an

wanted by the consumers and owning a good enough environmentally friendly production process is the absence

capability but still needed some correction to achieve of definitive work operating standards. To meet the quality

world class home industry of national and international standard products that are

environmentally friendly, it requires an applicable

Keywords:- Defect, Green Quality Improvement, Six Sigma, standardization of production processes so that quality

Traditional Brass Casting Craft. standards can be achieved.

I. INTRODUCTION III. METHODOLOGY

The craftsmen traditional Majapahit cast brass joined The production process of making Majapahit brass

in a ganesha cooperative formed in 2005. The quality of sculptures still using traditional equipment. The production

eco-friendly improvement or green quality improvement is system begins from making the master mold and preparation

now very popular for consumers [1],[2],[3]. It is shown by of raw materials, the casting process is performed, then

the greater awareness of consumers to obtain an adequate, cooling process and the release of sculptures cast from the

safe, and eco-friendly product. Consumers are willing to pay mold, as well as finishing and dyeing processes.

more for eco-friendly products [4].

The production process of making Majapahit brass cast

Changes in consumer awareness has led to large and is still traditional using simple equipment. The production

small industries indirectly must pay attention to the system begins with the making of the master mold and

environment and are responsible for not harming the preparation of raw materials, then the casting process is

environment. Resulting product is not only feasible and safe carried out, then the cooling process and removal of the cast

but in the production process must be clean and eco-friendly

IJISRT20AUG266 www.ijisrt.com 583

Volume 5, Issue 8, August – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

sculpture fromthe mold, as well as the finishing and coloring Factor causes of these defects are caused and are

process. directly related to humans, machines, methods, materials,

and environment [5]. Work shown in Figure 2 Fishbone

The brass cast craftsmen are incorporated in the diagram.

Ganesha cooperative that was formed since 2005.

Researchers are very interested in the traditional brass cast

of Majapahit because until now it is still survive in modern

era. From the results of preliminary observations obtained

the average sales data of brass cast craftsmen which came

from the members of the Ganesha cooperative for one year.

From the survey results in the field of data in general

the total production is 3,000 units to 1,239 units the number

of defective products. After doing research in the field of

product defects, can be broadly categorized types of defects

were found to be four types: defects or perforated holes

,disability rats, rough surface defects and disability cracks.

The research stages can be seen in Figure 1 below:

Fig 2:- Fishbone Diagram

Product defect repair process to define a process

improvement process model needs to be known to be used,

namely Suppliers - Inputs - Processes - Outputs - Customers

shown in Figure 3.

Fig 1:- Research Stage Fig 3:- Suppliers-Inputs-Processes-Outputs-Customers

IV. RESUTS AND DISCUSSIONS Suppliers - Inputs - Processes - Outputs - Customers

diagram illustrates the process becoming the focus of the

The results of several previous studies are still in the project. There are five elements of this diagram are:

form of normative suggestions, there are no clear operating Supplier of raw materials such as brass collectors or trashy

standards for work, there is no standardization of processes, brass scrap materials in the surrounding craftsmen’s area.

equipment, materials and supervision. The research only Input the process is brass which had been merged in the

discusses application theory, quality improvement and sales Smelting Process. Process, Consisting of Molding,

which have no consideration to eco-friendly factors. Smelting, Casting, Cooling, Inspecting and Finishing.

Output after all stages of the process is done it will produce

Thus, this research is important to be carried out to cast brass handicraft products. Customer, Is the process of

improve the quality and sales of Majapahit's traditional brass the finished product to the customer.

cast products which are eco-friendly. By increasing human

resources, standardizing processes, equipment, materials and A. Counting Defect Per Unit and Defect Per Million

supervision, eco-friendly production efficiency can be Objects

achieved. Before calculating process capability, first calculate the

value of Defect Per Unit [6]-[7]. Defect Per Unit calculation

Based on observations and interviews with cast brass is to give a general idea of the number of defects that occur

craftsmen joined in cooperative direct Ganesha, the most every unit. In this study, the unit is categorized brass casting

dominant cause of the product defect occurs in: the process product, so that the meaning Defect Per Unit is the number

of making a master mold, raw material melting process, the of defects that occur in every cast brass products. Defect Per

process casting. Unit value calculation is generally obtained from a simple

IJISRT20AUG266 www.ijisrt.com 584

Volume 5, Issue 8, August – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

calculation, the number of defects divided by the total The following is a comparison of the number of

number craft production of cast brass. defects that occur in every cast brass products shown in

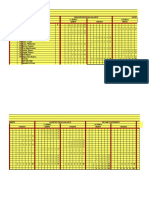

Table 1.

No. Total Production Total Disability Defect Per Unit Defect Per Million Objects Sigma value

1 250 106 0.424 424 000 1.65

2 250 97 0,388 388 000 1.75

3 500 234 0.468 468 000 1.55

4 500 229 0.458 458000 1.65

5 500 244 0,488 488 000 1.55

6 250 75 0.3 300000 2.05

7 250 69 0,276 276000 2.05

8 500 185 0.37 370000 1.85

mean 375 154.875 0.3965 396 500 1.7625

a.The results of Author’s research

Table 1:- Detect Per unit and detect er million objects.

From the calculation of Table 1, it can be seen that the Development of metal-chemical coating techniques

defects of brass handicraft products reach the sigma level of brass metal coloring is still done by craftsmen of Majapahit

1.7625 or are at the level 2 sigma condition with a possible brass cast. So that the resulting colors are not evenly

damage of 396,500 for a million times the production distributed in certain parts. By using metal-chemical coating

process or 39.65% Defect Per Million Objects. techniques in addition to coating the metal it is also able to

resist corrosion of the metal. The resulting color is more

This certainly becomes a loss for craftsmen if there is no flexible and varied so that it can meet customer desires.

improvement in the production process. To reduce the level

of product damage or defects produced, it is necessary to The application of green productivity in eco-friendly

increase the level of sigma in each production process. quality improvement is laid out Waste Reduction. By

applying 3R; reduce, reuse, and recycle as an effort to

B. Improve Phase improve the quality which is eco-friendly [8],[2],[3].

The aim of the improve phase is to find and implement Suggestions of 3R’s application in cast brass handicraft in

solutions that will eliminate the cause of the problem, home industry; Reducing the using of firewood or charcoal

reduce variety process and also prevent the same mistakes in burning process changed by using gas. Reuse the remains

happen. There some ways to reach those aims for instance. of sand mold is able to be smelted and reused for the mold

of the next production. Recycle is using raw material from

Generate Creative Ideas trash which made from brass recycled in smelted raw

This creative idea aims to develop the Majapahit material.

traditional brass cast industry, especially in the production

process. The creative ideas that are possible to do are: From the shorter time in the combustion process, the less

pollutants produced, let alone using electricity, and the

Design development and mold making this mold design environmentally friendly production process can be

is made manually, it is possible to use computer numerically achieved [9],[10],[11],[12],[13]. Development of metal-

controlled. In addition to good accuracy, the speed can also chemical coating techniques. Brass metal coloring is still

be measured so that it can save production time. done by craftsmen of Majapahit brass cast. So that the

resulting colors are not evenly distributed in certain parts.

Development of furnaces traditional burning stoves used

to use firewood as fuel. This process requires a long time in By using metal-chemical coating techniques in

heating and the heating results are also uneven. The addition to coating the metal it is also able to resist corrosion

resulting temperature cannot be stable in the heating of the metal. The resulting color is more flexible and varied

chamber often causes one of the factors causing failure in so that it can meet customer desires.

the production process. By using modern furnace commonly

used in the ceramic industry, the heat produced is stable and Material Management

can be measured so that the perfection of the results can be Material here is the pure brass or wreckage of brass

achieved. Besides that the shorter time in the combustion which has been processed before. The function of material

process, the less pollutants produced, let alone using management is responsible in planning, sourcing,

electricity, and the environmentally friendly production purchasing, storing, and controlling [14].

process can be achieved.

IJISRT20AUG266 www.ijisrt.com 585

Volume 5, Issue 8, August – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Suggestions of material management’s application in Cast brass handicraft products offered must be able to

home industry of cast brass handicraft; planning an accurate meet consumers desires and needs. Especially in the

plan in the application of raw material depends on guarantee of product quality, and timeliness in accordance

consumers’ request. Sourcing having cooperation with brass with the order.

wreckage wholesaler for being supplier of brass. Purchasing

of raw material can be cooperating with Ganesha The price of brass craft products must be able to

cooperation as colleague of craftsman in case of fund. compete with other products on the market. By following

Storing by the limit of the land. the standard market prices both domestically and abroad.

Craftsman should have a warehouse to save the raw Place in (marketing mix) commonly referred to as

material coordinated by the cooperation. Controlling the use distribution channels, in this case from brass cast craftsmen

of raw material through the cooperation hopefully the to the hands of customers. Special delivery or express

availability of raw material is guaranteed. Preventing the package makes it easy to send or distribute products with

crisis of raw material which causes rising price of material additional shipping costs adjusted for distance.

as balancer of material price in market.

Promotion of marketing spread both directly (direct

Marketing Mix Brass Craft Product marketing) and by using technological advances, especially

The marketing of brass cast crafts has only relied on the internet. To reach marketing to international level, you

orders from customers, especially customers who have art can use internet access or social media, for example

shops in the cities of Bali and Yogyakarta. To increase (Facebook).

sales, a system that is used in marketing (marketing mix)

[15],[16],[17] is needed, which includes: Standardization of Brass Craft Process Acording to

MMSE

Based on a survey of good product results in SMEs

cast brass craftsmen who are members of the Ganesha

cooperative. Then it can be concluded in a standard table

[18] of production processes that can produce good products

shown in Table 2.

No Stages of production Tools or materials Process

Making master Giving oil for every five times in making

1 Cement and Silicone

mold wax molds

Sifting materials from a mixture of other

materials to produce pure metal brass for

2 Smelting raw materials Smelting furnaces and brass metal

raw materials is obtained from brass

wraps

The casting process is carried out at a

3 Casting Metal thermometer (Thermocouple) temperature of 90000 Celsius -1.0500 0

Celsius

Brass cast results are placed in an open

4 Cooling Fan (Air Cooler)

space with free air circulation

Every connecting welding process uses

5 Welding Clamping tools (Vise) clamps so the results can be precise and

even

Giving a polished green stone every time

6 Refining Grinding and Green stone

is used for five brass craft units

Stainless steel container, material for Mix all ingredients in a stainless steel

antique green color (BTC MS 040 T container and heat it to a temperature of

7 Staining

250 gram and BTC 047T 250 gram 700 0 Celsius then dip brass metal for one

for every 5 liters of water minute

b. The results of Author’s research

Table 2:- Standart Cast Brass Production Process.

Final expectation of the value of sigma after improvement for four months there was a change in the

improvement. value of sigma.

From the results of improvement, it is expected that the The following is a comparison of the sigma values of

change in the value of Sixma is better than before [28],[29]. the production process before and after improvements are

This means an increase in the value of sixma in accordance made as shown in Table 3.

with the desired expectations. After an experiment of

IJISRT20AUG266 www.ijisrt.com 586

Volume 5, Issue 8, August – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Total Defect Defect

Total Disability Sigma Value

No Product Per Unit Per Million Objects

before After before After before After before After

1 250 106 52 0.424 0.208 424 000 208 000 1.65 3.55

2 250 97 43 0,388 0.172 388 000 172 000 1.75 3.65

3 500 234 80 0.468 0.36 468 000 360000 1.55 3.65

4 500 229 67 0,458 0.35 458000 350000 1.65 3.8

5 500 244 93 0,488 0.38 488 000 380000 1.55 3.5

6 250 75 21 0.3 0.84 300000 84000 2.05 4.25

7 250 69 15 0,276 0.06 276000 60000 2.05 4.4

8 500 185 74 0.37 0.262 370000 262 000 1.85 3.8

mean 375 154.8 59.5 0.3965 0.235 396 500 235000 17.625 3.725

The results of Author’s research

c.

Table 3:- Standart Cast Brass Production Process.

C. Expectations final sigma value after repair V. CONCLUSION

From the result of the expected improvement to

changes sixma better than ever. This means that an increase Application of a good standard production process

in the value of sixma according to the desired expectations. based on standard SMEs cast brass crafts men. So as to

After a four-month experiment in no change in the value of reduce the number of defective products with calculation of

sigma. the value of the rate sigma 1,7625 or are in levels 2 sigma

before the repair, with possible damage to 396,500 to one

Comparison of the sigma value of the production million times the production process. Increased to levels

process before and after improvement as shown in Table 1 sigma with the 3,725 level with possible damage to 235,500

and 2 diagram is shown by the reduction in the number of to one million times the production process after repair. so

defects of cast brass handicraft products of the mean value the statisfaction of customers can be met with the assurance

of 154,8 was reduced to 59,5. of product quality, and timeliness in accordance with the

order.

While the results of the calculation of the value of

sigma defects cast brass handicraft products from 1.7625 SUGGESTION

sigma level or set of conditions becomes 3.725 sigma level

2 or level 4 in a state with the possibility of damage by Expansion of Majapahit's brass craft market

235,000 to a million times the production process. segmentation through Ganesha cooperatives both locally

and abroad using internet technology. The Ganesha

Comparison of sigma and the mean value in the form Cooperative should actively participate in and conduct

of a diagram is shown in Figure 4 Comparison Sigma And training or workshops in collaboration with government

Mean Value [19],[20]. agencies (Disperindag) and competent private sector.

The Ganesha Cooperative should actively participate

in exhibitions at home and abroad held by government or

private agencies. Cooperative Ganesha to be active in

marketing Majapahit cast brass handicraft products in

collaboration with Artshop or star hotels

REFERENCES

[1]. B. Devipriyaand M. Nandhini,“A Study on Consumer

Attitude towards Eco-Friendly Products in

Coimbatore City”,International Journal of

Management and Development Studies, vol. 5, pp. 1-

5, https://www.ijmds.in/journalfile, 2016.

Fig 4:- Comparison Sigma And Mean [2]. F. Handoko, E. Nursanti dan S. Sutriyono, “Aplikasi

Pendekatan Perbaikan Terus Menerus guna Mencapai

Green Industrial System yang Berkelanjutan”,

Prosiding SENATEK,1 (A), pp. 866-870, www.

ejournal.itn.ac.id, 2015. [in bahasa]

IJISRT20AUG266 www.ijisrt.com 587

Volume 5, Issue 8, August – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

[3]. F. Handoko, E. Nursanti, G. Gatot, L. Mulyadi, J. [13]. I. Mouludi, K. Rukun, N. Syah, S. Hafridana, M. I.

Hutabarat dan Kustamar, “Green Industrial System in Senjawati, B. H. Hayadi, “Expert System Design As

Indonesia”, Journal of Telecomunication, Electronic A Quality Control Efforts In The Packaging Process

and Computer Engineering, https://www.matec- Tea Rgb 220 Ml Package Bottle In Pt. Sinar Sosro

conferences.org/articles/matecconf, 2018. Kpb Deli Serdang”, International Journal of Scientific

[4]. L. Agnieszka, “Current Trends In The Consumer & Technology Research, vol. 8, no. 6, pp. 82-

Behaviour Towards Eco-Friendly Products”, 87,//www.ijstr.org, 2019.

Economic and Environmental Studies (E&ES), [14]. Z. Manalu, and Y. D. Lestari,“Project Effectiveness

vol.152,no.2,pp.115- Improvement: A Case Study in PT.X,” Journal of

129,http://www.econstor.eu/handle/10419/178880, Bussiness and Management, vol. 4, pp. 587-593,

2015. https://journal.sbm.itb.ac.id, 2015.

[5]. D. Optimasi, H. Wahyono and F. Akurat, “Analysis [15]. Chockalingam, SN., and Isreal, DJ,.Redesigning, “The

Quality Control Of Batik Products”, International Marketing Mix For Eco-Friendly Product

Journal of Scientific & Technology Research, vol. 7, Consumption Among Non-Purchasers In India”,

no. 7, pp. 22-27,//www.ijstr.org, 2018. Management & Marketing: Challenges For The

[6]. A. Kholil and A. A. Jumhur.,“Waste Management Knowledge Society, vol. 11, no. 1, pp. 355-370,

Based on 3R in Mutiara Waste Banks Bekasi City https://doi.org/10.1515/mmcks, 2016.

Indonesia”, International Journal of Scientific & [16]. B. Hermawan, S. Basalamah, A. Djamereng, A.

Technology Research, vol. 8, no. 3, pp. 71– Plyriadi,“Effect of Service Quality and Price

76,//www.ijstr.org, 2018. Perception on Corporate Image, Customer Satisfaction

[7]. Firmansyah“Meningkatkan Mutu Kain Tenun Ikat and Customer Loyalty among Mobile

Tradisional Di Desa/Kelurahan Roworena Secara Telecommunication Services Provider”, IRA-

Berkesinambungan Di Kabupaten Ende Dengan International Journal of Management & Social

Pendekatan TQM, ”Institute of Technology National Sciences, Vol.8, Issue 01 pp. 62-73,

(ITN), Malang, vol. 3 issue 1, pp. 26-27, www. https://www.semanticscholar.org, 2017.

ejournal.itn.ac.id, 2017. [in bahasa] [17]. Makmur and Saprijal, ”Strategi Pemasaran Dalam

[8]. E. Nursanti, R.I. ,Purnama dan I.B. Suardika, MeningkatkanVolume Penjualan (Studi Pada S-Mart

“Optimasi Kapasitas Produksi untuk Mendapatkan Swalayan Pasir Pangairan)”, Jurnal Ilmiah Cano

Keuntungan Maksimum dengan Linier Programin”, Ekonomos, Vol.3, No.1, pp. 82-93,

Performa : Media Ilmiah Teknik Idustri 14 (1), pp. 22- https://www.neliti.com/publications/58203/strategi-

23, www. ejournal.itn.ac.id, 2015. [in bahasa] pemasaran-dalam-meningkatkan-volume-penjualan-

[9]. R.M.S. Avie dan E. Nursanti, “Aplikasi Continuos studi-pada-s-mart-swalaya, 2015. [in bahasa]

Improvement Terhadap Pemeliharaan Overhoul [18]. S. Handayani, E. Nursanti dan F . Handoko,

Pesawat Tempur Hawk Mk-209 TNI AU”, Prosiding “Perencanaan Perbaikan Berkelanutan (CI-PDCA)

SENIATI, C. 108-C. 115, www. ejournal.itn.ac.id Untuk Mewujudkan Efesiensi Energi Pada Sistem

2016. [in bahasa] Perkantoran”, Prosiding SENIATI, C. 139-C,

[10]. Mudit, Saxena, KVN. S. Rao “Quality Management, https://www.semanticscholar.org, 2016. [in bahasa]

Total Quality Management And Six Sigma”, [19]. Brian, J. Galli, M. A. Kaviani,”The impacts of Risk on

International Journal of Scientific & Technology deploying and sustaining Lean Six sigma initiatives”,

Research, vol. 8, issue 12, pp. 32-47,www.ijstr.org, International Journal of Risk and Contingency

2019. Management, Volume 7, Issue 1, pp. 162-173,,

[11]. S. Sahoo, and S. Yadav, "Effectiveness of Lean https://www.researchgate.net/publication/320740856_

Manufacturing Technologies for Improving Business The_Impacts_of_Risk_on_Deploying_and_Sustaining

Performance: A studyof Indian Manufacturing _Lean_Six_Sigma_Initiatives, 2018.

Industries", World Academy of Science, Engineering [20]. S. Elapanda, U.V.A. Rao, M. Manideep “Review On

and Technology : International Journal of Social, Effects Of Critical Social Factors In Application Of

Behavioral, Educational, Economic, Business and Lean Six Sigma For Manufacturing Industries”,

Industrial Engineering, vol. 11, no.2, pp. 318- International Journal of Scientific & Technology

325,https://publications.waset.org/10006349/effective Research, ISSN 2277-8616,vol. 8, issue 11, pp. 72-83,

ness-of-lean-manufacturing-technologies-on- //www.ijstr.org, 2019.

improving-business-performance-a-study-of-indian-

manufacturing-industries, 2017.

[12]. H. S. Al-Dhaafri, A. K. Al-Swidi, and R. Z. B.

Yusoff, "The mediating role of total quality

management between the entrepreneurial orientation

and the organizational performance", The TQM

Journal, vol. 28, no. 1, pp. 1754-2731,

https://www.semanticscholar.org, 2016.

IJISRT20AUG266 www.ijisrt.com 588

You might also like

- Lean Process Management Implementation in Ceramic Industry: K. Anuj Babu, A. Thirugnanam and S. P. Sundar Singh SivamDocument16 pagesLean Process Management Implementation in Ceramic Industry: K. Anuj Babu, A. Thirugnanam and S. P. Sundar Singh SivamAdat Ya MuhabbatNo ratings yet

- Application of Lean Kaizen in Productivity Improvement and Safety Measures in A Manufacturing IndustryDocument6 pagesApplication of Lean Kaizen in Productivity Improvement and Safety Measures in A Manufacturing IndustryGizachew ZelekeNo ratings yet

- 4 - The Application of Six Sigma To Improve The Yield of Plastic Injection MoldingDocument19 pages4 - The Application of Six Sigma To Improve The Yield of Plastic Injection Moldingleylagale27No ratings yet

- Procesos de Manufactura: Dr. Ing. Jaime Salazar MontenegroDocument35 pagesProcesos de Manufactura: Dr. Ing. Jaime Salazar MontenegroUrsula alca floresNo ratings yet

- Study of Implementing 5S Techniques inDocument4 pagesStudy of Implementing 5S Techniques inعزالدين الحسينيNo ratings yet

- Mansur 2016 IOP Conf. Ser. - Mater. Sci. Eng. 105 012006Document11 pagesMansur 2016 IOP Conf. Ser. - Mater. Sci. Eng. 105 012006PhucNo ratings yet

- Applying Lean Concepts to Reduce Waste in a Plastic Pipe Manufacturing IndustryDocument18 pagesApplying Lean Concepts to Reduce Waste in a Plastic Pipe Manufacturing IndustryAntonius PrakosaNo ratings yet

- Application of Lean Manufacturing in The Painting Plant Manufacturing Process by Reducing Waste Waiting A Case Study at PT - Koba Multi IndonesiaDocument10 pagesApplication of Lean Manufacturing in The Painting Plant Manufacturing Process by Reducing Waste Waiting A Case Study at PT - Koba Multi IndonesiaTJPRC PublicationsNo ratings yet

- Reduction of Post-Kiln Rejections For Improving SuDocument7 pagesReduction of Post-Kiln Rejections For Improving Sujose manuel gomez jimenezNo ratings yet

- E Catelogue 2020Document8 pagesE Catelogue 2020Chetan SharmaNo ratings yet

- TLS PDFDocument36 pagesTLS PDFAmrita KhatriNo ratings yet

- System Implementation Traffic LightDocument36 pagesSystem Implementation Traffic LightDurbar DasguptaNo ratings yet

- JARIE Volume5 Issue4 Pages306-323Document19 pagesJARIE Volume5 Issue4 Pages306-323dzdvzdvcsNo ratings yet

- Environmental Management System: Group MembersDocument20 pagesEnvironmental Management System: Group MembersZubarya KianiNo ratings yet

- Different Departments of Glass and Fertilizer Industries (CH-18028)Document10 pagesDifferent Departments of Glass and Fertilizer Industries (CH-18028)Maya's InsightNo ratings yet

- Cipet Project WorkDocument44 pagesCipet Project WorkFarooq Naregal100% (2)

- Design ToolDocument7 pagesDesign ToolViola AtienoNo ratings yet

- Defects Reduction in A Pump Manufacturing Industry Using Six Sigma MethodologiesDocument7 pagesDefects Reduction in A Pump Manufacturing Industry Using Six Sigma MethodologiesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Ramie Decortication Waste Bio-Briquette Business Model CanvasDocument9 pagesRamie Decortication Waste Bio-Briquette Business Model CanvasanasbunyaminNo ratings yet

- Manufacturing Continuous Improvement Using Lean Six Sigma: An Iron Ores Industry Case ApplicationDocument8 pagesManufacturing Continuous Improvement Using Lean Six Sigma: An Iron Ores Industry Case Applicationesuarezc_atlNo ratings yet

- Q1 - 5S - Articulo MejoraDocument6 pagesQ1 - 5S - Articulo Mejoraelioglp1No ratings yet

- Critical Study On Vital Factors Influencing Productivity ImprovementDocument8 pagesCritical Study On Vital Factors Influencing Productivity ImprovementIJRASETPublicationsNo ratings yet

- A Lean Six Sigma Project To Reduce Waste and Variability in A Confectionery ManufacturingDocument11 pagesA Lean Six Sigma Project To Reduce Waste and Variability in A Confectionery ManufacturingVishvas SutharNo ratings yet

- Sine International Institute of Technology: Green ManufacturingDocument16 pagesSine International Institute of Technology: Green ManufacturingAmit KainturaNo ratings yet

- Green ManufacturingDocument21 pagesGreen Manufacturingpankaj kumar100% (1)

- Teknologi Manufaktur IDocument21 pagesTeknologi Manufaktur IRaka-theredsdevilslovers CinthaCeiwectia Dont'likeplaygirlsNo ratings yet

- Selection of Materials and Manufacturing Processes Towards Achieving Green Engineering M. M. Haque, Tuti Y. Alias and Ahmad F. IsmailDocument10 pagesSelection of Materials and Manufacturing Processes Towards Achieving Green Engineering M. M. Haque, Tuti Y. Alias and Ahmad F. IsmailAndyNo ratings yet

- Analysis Problem and Improvement of Appearance Aesthetics Product Model HC C5 / XT With Method of Plan-Do-Check-Action (PDCA) in Pt. XXXXDocument8 pagesAnalysis Problem and Improvement of Appearance Aesthetics Product Model HC C5 / XT With Method of Plan-Do-Check-Action (PDCA) in Pt. XXXXAnonymous lAfk9gNPNo ratings yet

- CSTNGDocument5 pagesCSTNGAbate TolinaNo ratings yet

- Green PLM Framework for Sustainable Product LifecycleDocument3 pagesGreen PLM Framework for Sustainable Product LifecycleKulkarni Prathmesh PrakashNo ratings yet

- Makalah 122130082Document12 pagesMakalah 122130082Annisa Bintang AyuNo ratings yet

- ANU Final ReportDocument84 pagesANU Final ReportRanjith Kumar DNo ratings yet

- Approach of Green and Lean Manufacturing Study of The Small Industries in BangladeshDocument4 pagesApproach of Green and Lean Manufacturing Study of The Small Industries in BangladeshMunem ShahriarNo ratings yet

- Fiberline Screenroom Improvements and The Benefits in Pulp QualityDocument5 pagesFiberline Screenroom Improvements and The Benefits in Pulp QualityBastian Richard SitohangNo ratings yet

- Final Exam PDFDocument11 pagesFinal Exam PDFwaqasNo ratings yet

- Case Study On Lean Manufacturing System Implementation in Batch Type Manufacturing IndustryDocument18 pagesCase Study On Lean Manufacturing System Implementation in Batch Type Manufacturing IndustryCool BuddyNo ratings yet

- Part B CompleteDocument81 pagesPart B CompleteRanjith Kumar DNo ratings yet

- The Development of Design Dry Cake Packaging at The SME-Scale Industry Using Kansei EngineeringDocument5 pagesThe Development of Design Dry Cake Packaging at The SME-Scale Industry Using Kansei EngineeringInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Materials Today: Proceedings: Pravin Jadhav, Nachiket EkboteDocument7 pagesMaterials Today: Proceedings: Pravin Jadhav, Nachiket EkboteDimitris PlotasNo ratings yet

- An Application of Six Sigma MethadologyDocument26 pagesAn Application of Six Sigma MethadologyBrijesh PandeyNo ratings yet

- Optimization of Process Parameters in Extrusion of PVC Pipes Using Taguchi Method IJERTV8IS0100291Document4 pagesOptimization of Process Parameters in Extrusion of PVC Pipes Using Taguchi Method IJERTV8IS0100291Marcos RamisNo ratings yet

- IJPMB070301MAITYDocument29 pagesIJPMB070301MAITYpwunipaNo ratings yet

- Lolyka Molding - JPKMDocument7 pagesLolyka Molding - JPKMlolyka dewiNo ratings yet

- Green Supply Chain ManagementDocument30 pagesGreen Supply Chain ManagementSoorya HaridasanNo ratings yet

- Material Science: Prof. Satish V. KailasDocument4 pagesMaterial Science: Prof. Satish V. KailasHagere EthiopiaNo ratings yet

- Kalpakjian 6e iCARE Ch00 OnlineDocument47 pagesKalpakjian 6e iCARE Ch00 OnlineAnas TubailNo ratings yet

- Improving The Productivity of Sheet Metal StampingDocument6 pagesImproving The Productivity of Sheet Metal Stampingkarla caaroNo ratings yet

- 1 s2.0 S2351978915000918 Main PDFDocument6 pages1 s2.0 S2351978915000918 Main PDFMiguel HerreraNo ratings yet

- Green Supply ChainDocument75 pagesGreen Supply ChainApoorv SharmaNo ratings yet

- Hit 301 Internship Report 2016Document91 pagesHit 301 Internship Report 2016BLESSWARD MUTSOTSONo ratings yet

- Implementation of Lean Six Sigma PDFDocument8 pagesImplementation of Lean Six Sigma PDFRenato MayorgaNo ratings yet

- A Case Study AmboDocument7 pagesA Case Study Ambokene malakuNo ratings yet

- Productivity Improvement Through Lean ManufacturingDocument30 pagesProductivity Improvement Through Lean ManufacturingmanikandaprabuNo ratings yet

- Jurnal SENOPATI: Implementasi Dan Green Manufacturing Guna MeningkatkanDocument12 pagesJurnal SENOPATI: Implementasi Dan Green Manufacturing Guna Meningkatkansaiful FNNo ratings yet

- Analysis of Lean Manufacturing Waste Factors in The Brewing Industry of Ensenada, Baja California, MexicoDocument9 pagesAnalysis of Lean Manufacturing Waste Factors in The Brewing Industry of Ensenada, Baja California, MexicoIJAR JOURNALNo ratings yet

- Prasad 2016Document8 pagesPrasad 2016kamalashrafhkNo ratings yet

- IOP Conf. Series: Materials Science and Engineering 308 (2018) 012004Document9 pagesIOP Conf. Series: Materials Science and Engineering 308 (2018) 012004Frank CordovaNo ratings yet

- Project Report On Current Market Share Market Potential PaintsDocument75 pagesProject Report On Current Market Share Market Potential PaintsRoyal Projects100% (1)

- Bottles, Preforms and Closures: A Design Guide for PET PackagingFrom EverandBottles, Preforms and Closures: A Design Guide for PET PackagingRating: 4.5 out of 5 stars4.5/5 (3)

- Formulation and Evaluation of Poly Herbal Body ScrubDocument6 pagesFormulation and Evaluation of Poly Herbal Body ScrubInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Comparatively Design and Analyze Elevated Rectangular Water Reservoir with and without Bracing for Different Stagging HeightDocument4 pagesComparatively Design and Analyze Elevated Rectangular Water Reservoir with and without Bracing for Different Stagging HeightInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Explorning the Role of Machine Learning in Enhancing Cloud SecurityDocument5 pagesExplorning the Role of Machine Learning in Enhancing Cloud SecurityInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Review: Pink Eye Outbreak in IndiaDocument3 pagesA Review: Pink Eye Outbreak in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design, Development and Evaluation of Methi-Shikakai Herbal ShampooDocument8 pagesDesign, Development and Evaluation of Methi-Shikakai Herbal ShampooInternational Journal of Innovative Science and Research Technology100% (2)

- Studying the Situation and Proposing Some Basic Solutions to Improve Psychological Harmony Between Managerial Staff and Students of Medical Universities in Hanoi AreaDocument5 pagesStudying the Situation and Proposing Some Basic Solutions to Improve Psychological Harmony Between Managerial Staff and Students of Medical Universities in Hanoi AreaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Survey of the Plastic Waste used in Paving BlocksDocument4 pagesA Survey of the Plastic Waste used in Paving BlocksInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Electro-Optics Properties of Intact Cocoa Beans based on Near Infrared TechnologyDocument7 pagesElectro-Optics Properties of Intact Cocoa Beans based on Near Infrared TechnologyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Auto Encoder Driven Hybrid Pipelines for Image Deblurring using NAFNETDocument6 pagesAuto Encoder Driven Hybrid Pipelines for Image Deblurring using NAFNETInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Cyberbullying: Legal and Ethical Implications, Challenges and Opportunities for Policy DevelopmentDocument7 pagesCyberbullying: Legal and Ethical Implications, Challenges and Opportunities for Policy DevelopmentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Navigating Digitalization: AHP Insights for SMEs' Strategic TransformationDocument11 pagesNavigating Digitalization: AHP Insights for SMEs' Strategic TransformationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Hepatic Portovenous Gas in a Young MaleDocument2 pagesHepatic Portovenous Gas in a Young MaleInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Review of Biomechanics in Footwear Design and Development: An Exploration of Key Concepts and InnovationsDocument5 pagesReview of Biomechanics in Footwear Design and Development: An Exploration of Key Concepts and InnovationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Automatic Power Factor ControllerDocument4 pagesAutomatic Power Factor ControllerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Formation of New Technology in Automated Highway System in Peripheral HighwayDocument6 pagesFormation of New Technology in Automated Highway System in Peripheral HighwayInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Drug Dosage Control System Using Reinforcement LearningDocument8 pagesDrug Dosage Control System Using Reinforcement LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Effect of Time Variables as Predictors of Senior Secondary School Students' Mathematical Performance Department of Mathematics Education Freetown PolytechnicDocument7 pagesThe Effect of Time Variables as Predictors of Senior Secondary School Students' Mathematical Performance Department of Mathematics Education Freetown PolytechnicInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mobile Distractions among Adolescents: Impact on Learning in the Aftermath of COVID-19 in IndiaDocument2 pagesMobile Distractions among Adolescents: Impact on Learning in the Aftermath of COVID-19 in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Securing Document Exchange with Blockchain Technology: A New Paradigm for Information SharingDocument4 pagesSecuring Document Exchange with Blockchain Technology: A New Paradigm for Information SharingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Perceived Impact of Active Pedagogy in Medical Students' Learning at the Faculty of Medicine and Pharmacy of CasablancaDocument5 pagesPerceived Impact of Active Pedagogy in Medical Students' Learning at the Faculty of Medicine and Pharmacy of CasablancaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Intelligent Engines: Revolutionizing Manufacturing and Supply Chains with AIDocument14 pagesIntelligent Engines: Revolutionizing Manufacturing and Supply Chains with AIInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Enhancing the Strength of Concrete by Using Human Hairs as a FiberDocument3 pagesEnhancing the Strength of Concrete by Using Human Hairs as a FiberInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Exploring the Clinical Characteristics, Chromosomal Analysis, and Emotional and Social Considerations in Parents of Children with Down SyndromeDocument8 pagesExploring the Clinical Characteristics, Chromosomal Analysis, and Emotional and Social Considerations in Parents of Children with Down SyndromeInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Supply Chain 5.0: A Comprehensive Literature Review on Implications, Applications and ChallengesDocument11 pagesSupply Chain 5.0: A Comprehensive Literature Review on Implications, Applications and ChallengesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Teachers' Perceptions about Distributed Leadership Practices in South Asia: A Case Study on Academic Activities in Government Colleges of BangladeshDocument7 pagesTeachers' Perceptions about Distributed Leadership Practices in South Asia: A Case Study on Academic Activities in Government Colleges of BangladeshInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Advancing Opthalmic Diagnostics: U-Net for Retinal Blood Vessel SegmentationDocument8 pagesAdvancing Opthalmic Diagnostics: U-Net for Retinal Blood Vessel SegmentationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Making of Self-Disposing Contactless Motion-Activated Trash Bin Using Ultrasonic SensorsDocument7 pagesThe Making of Self-Disposing Contactless Motion-Activated Trash Bin Using Ultrasonic SensorsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Natural Peel-Off Mask Formulation and EvaluationDocument6 pagesNatural Peel-Off Mask Formulation and EvaluationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Beyond Shelters: A Gendered Approach to Disaster Preparedness and Resilience in Urban CentersDocument6 pagesBeyond Shelters: A Gendered Approach to Disaster Preparedness and Resilience in Urban CentersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Handling Disruptive Behaviors of Students in San Jose National High SchoolDocument5 pagesHandling Disruptive Behaviors of Students in San Jose National High SchoolInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Pranayam Resident Welfare Association (Regd.) : Cam Cum Utility InvoiceDocument1 pagePranayam Resident Welfare Association (Regd.) : Cam Cum Utility InvoiceDeepak VermaNo ratings yet

- Bidding DocumentsDocument82 pagesBidding DocumentsPalwasha GulNo ratings yet

- Advanced Process Control - Sustaining Benefits and CostsDocument20 pagesAdvanced Process Control - Sustaining Benefits and CostsHarshit SharmaNo ratings yet

- Decision TheoryDocument14 pagesDecision TheoryBless TettehNo ratings yet

- SAP S - 4HANA Cloud, Public Edition, 3-System Landscape - Upgrade & Maintenance ScheduleDocument9 pagesSAP S - 4HANA Cloud, Public Edition, 3-System Landscape - Upgrade & Maintenance ScheduleAnti VitaNo ratings yet

- Sec. 24. Election of Directors or Trustees.Document7 pagesSec. 24. Election of Directors or Trustees.Lean Rain SandiNo ratings yet

- Effectiveness of The Public Financial Management Assessment Tool or (PFMAT) in Strengthening The Financial Capability of Local Government Unit in Talavera, Nueva EcijaDocument10 pagesEffectiveness of The Public Financial Management Assessment Tool or (PFMAT) in Strengthening The Financial Capability of Local Government Unit in Talavera, Nueva EcijaKomal sharmaNo ratings yet

- Article Topic 1 PDFDocument16 pagesArticle Topic 1 PDFAli CollierNo ratings yet

- ProblemDocument2 pagesProblemchandra K. SapkotaNo ratings yet

- Financial ratios reveal SBI's strong performance compared to PNB and ICICI BankDocument16 pagesFinancial ratios reveal SBI's strong performance compared to PNB and ICICI BankGautmi Deepali PathakNo ratings yet

- Ejercicios ContabilidadDocument3 pagesEjercicios ContabilidadCarolina RvNo ratings yet

- A Detail Study On Implementation of Green Technology and Reverse Manufacturing Methods in Plastic Molding IndustryDocument7 pagesA Detail Study On Implementation of Green Technology and Reverse Manufacturing Methods in Plastic Molding IndustryInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- CASE STUDY ANALYSIS REPORT Eng Rev 2Document24 pagesCASE STUDY ANALYSIS REPORT Eng Rev 2Faishal Dzaky AffiantoNo ratings yet

- How Does Harrah's Integrate The Various Elements of Its Marketing Strategy To Deliver More Than The Results of Data Base Marketing?Document1 pageHow Does Harrah's Integrate The Various Elements of Its Marketing Strategy To Deliver More Than The Results of Data Base Marketing?Harshad SachaniNo ratings yet

- Bustax Compilation ExamsDocument194 pagesBustax Compilation ExamsRialeeNo ratings yet

- AS9100D Quality ManualDocument22 pagesAS9100D Quality ManualHoang TanNo ratings yet

- T MedicalDocument223 pagesT MedicalAssam JobNo ratings yet

- 9 - BSBPEF501 Appendix D - Work Goals, Plans and Activities Template Assessment 2cDocument2 pages9 - BSBPEF501 Appendix D - Work Goals, Plans and Activities Template Assessment 2cP APARNANo ratings yet

- IFRS 11 and 12 CPD September 2013Document64 pagesIFRS 11 and 12 CPD September 2013Nicolaus CopernicusNo ratings yet

- CrosbyDocument19 pagesCrosbyDr. Sanjay Mahalingam, Asst. Professor, Management & Commerce, SSSIHLNo ratings yet

- Capitalist Crew Corp JFC StramaDocument56 pagesCapitalist Crew Corp JFC StramaAkako MatsumotoNo ratings yet

- Architectural Record 2024-01Document124 pagesArchitectural Record 2024-01ricardoNo ratings yet

- Chapter 7 Problems: Problem #14 P. 7-57 Problem #15 P. 7-58Document3 pagesChapter 7 Problems: Problem #14 P. 7-57 Problem #15 P. 7-58Zyrene Kei ReyesNo ratings yet

- Business DirectoryDocument4 pagesBusiness DirectoryRegunathan PadmanathanNo ratings yet

- Chapter 6 Applications of Macroeconomics Theory As A Basis For Understanding The Key Economic Variables Affecting The BusinessDocument52 pagesChapter 6 Applications of Macroeconomics Theory As A Basis For Understanding The Key Economic Variables Affecting The Businessaladdin oidacraNo ratings yet

- Bank of Jamaica Brief HistoryDocument5 pagesBank of Jamaica Brief HistoryTechnicianccnaNo ratings yet

- Joint Cost - by ProductDocument15 pagesJoint Cost - by ProductRessa LarasatiNo ratings yet

- Strategy and Tactics of Integrative NegotiationDocument17 pagesStrategy and Tactics of Integrative NegotiationcristianaNo ratings yet

- COPC Inc Overview PresentationDocument43 pagesCOPC Inc Overview Presentationpradip_sinha86% (7)

- C. Castro Company-Cdc 2018Document42 pagesC. Castro Company-Cdc 2018Gennelyn Lairise Rivera100% (1)