Faster and more convenient charging with Osprey’s new electron-juggling Kempower chargers.

As we’ve emerged from the COVID lockdown, more and more of us have been driving our electric vehicles (EVs) long distances and looking for places to obtain a fast and convenient charge. Like other charging networks, Osprey is busy expanding its charging sites – both in terms of number of locations and number of chargers at each site – in response to increased demand. However, unlike other charging networks, Osprey is about to launch several new sites that feature some seriously impressive new charger tech, promising speed and convenience for EV drivers.

Getting the balance right

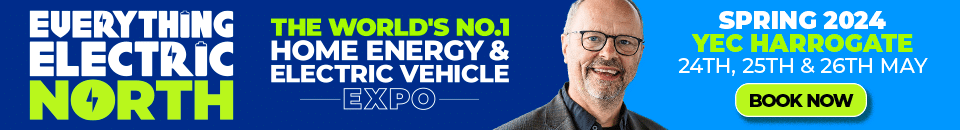

To build a rapid charging hub, you need to secure a big enough grid supply. With conventional rapid chargers, the total maximum power of all of the chargers installed must not exceed the agreed maximum power supply of the grid connection. Let’s say that we had a grid supply that can provide 400 kW of power. Now let’s try to build a rapid charging hub, first using conventional rapid chargers, then using Osprey’s clever new electron-juggling chargers:

Conventional rapid chargers

For our site, let’s use conventional rapid chargers with 100 kW of power output each: this means that our proposed rapid charging hub could accommodate (400 ÷ 100 = ) four of these rapid chargers without exceeding the site’s grid supply.

Now let’s say that four electric vehicles plugged into our hub. These vehicles are:

- An Audi e-tron 50 quattro with a maximum charge power of 125 kW

- A Volkswagen ID.4 Pro Performance with a maximum charge power of 125 kW

- An Kia e-Niro 64 kWh with a maximum charge power of 77 kW

- A Nissan LEAF 40 kWh with a maximum charge power of 50 kW

Each of our rapid chargers can output 100 kW. This means that the vehicles receive the following charging power each, as shown in Table 1:

So, the e-tron and the ID.4 are denied their full charging power, despite the e-Niro and LEAF both not fully utilising the power available to them from their chargers. In fact, looking at the power surplus from the e-Niro and LEAF, there is enough spare power to theoretically charge both the e-tron and the ID.4 at their full charging power of 125 kW. Unfortunately, conventional rapid chargers cannot usually share power between other units, and if they can, they tend to split their power in half between the two vehicles, even if one requires a lot more charging power than the other. This problem is exacerbated as the vehicles’ batteries fill up, and their charging power tapers off. If the LEAF’s charging power reduces to 25 kW, there would now be 75 kW of wasted power on that charger.

Whilst conventional rapid chargers continue to serve us well, it’s clear that there’s room to be more clever with our available power.

Kempower’s electron-juggling chargers

Osprey is about to launch its latest High-Power Chargers, from a Finnish company called Kempower. These have a number of useful features, the first of which you’ll see as soon as you arrive at the charging hub. Firstly, the cables are six-metres-long and spring-loaded, so they’re easy to lift and should reach the far corner of your car no matter which way you park – no more awkward U-turns having realised that the cable doesn’t reach! The “dispensers” are very compact, so they can be installed in more locations than some conventional chargers, and the cables’ temperature management negates the need for liquid cooling, reducing maintenance requirements and improving reliability.

Osprey have opted for a one-charger-per-bay set up with contactless and both CCS and CHAdeMO on each dispenser. In the near future, things could be even more convenient – Kempower’s chargers are configured for Plug and Charge, so you could simply drive up, plug in and the charging and billing sorts itself out, bringing everyone a level of convenience that so far is largely confined to Teslas.

So far, so convenient, but how are they potentially capable of charging your EV faster than conventional chargers?

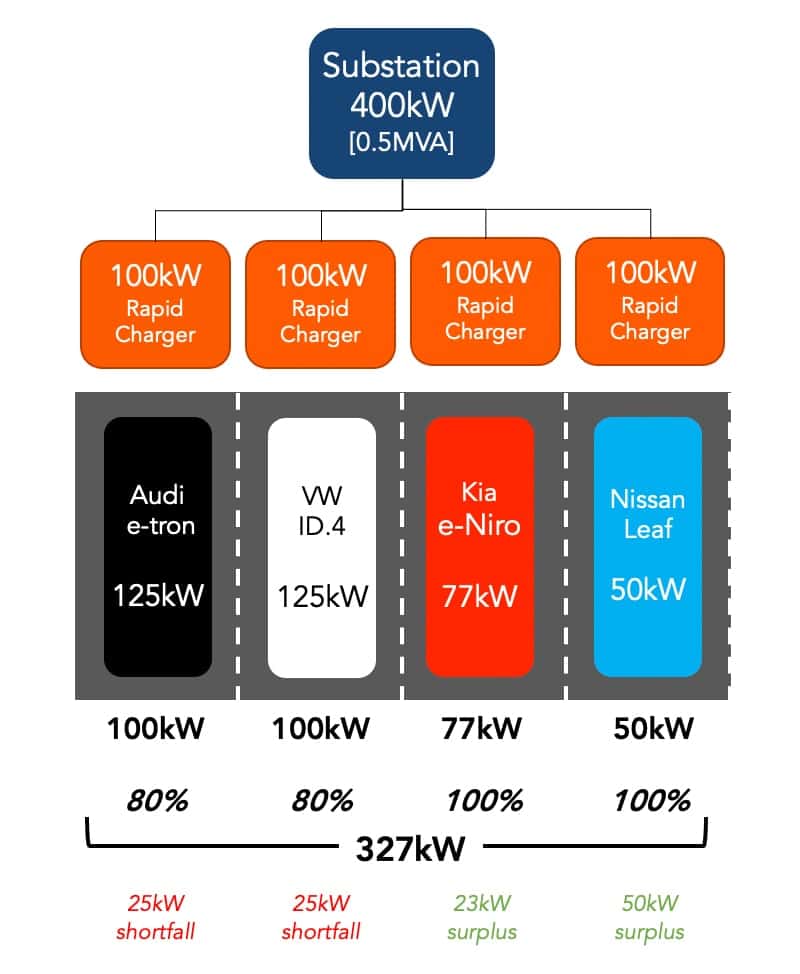

The Kempower solution consists of several dispensers, each typically capable of providing up to 125 kW to an EV, all of which are connected to a central power bank. The power bank consists of several 25 kW power modules – in the case of our proposed site, we could have (400 ÷ 25 = ) sixteen of these power modules. The power modules can be assigned to any dispenser as the power bank sees fit, and several modules can be linked up to one dispenser to provide the charging power requested by the EV.

The Kempower system constantly monitors the charging power of each EV, and automatically reassigns power modules throughout charging sessions from EVs whose charging power is tapering off, to those that are capable of accepting an extra boost in charging power.

Say our site had four Kempower dispensers. With normal charging infrastructure, installing 4x 125 kW rapid chargers on a 400 kW substation wouldn’t be possible. However, the chances of all four cars pulling 125 kW at the same time are slim – many EVs have a maximum charge power of 100 kW or less, and EVs reduce their charging power as their battery fills up. The Kempower solution takes advantage of this, with some clever electron-juggling in the form of “dynamic load management,” to make the most of its available grid supply without exceeding it, whilst allowing any dispenser to provide more power modules to faster-charging vehicles that need them.

Now let’s say that the same four cars as before plugged into these dispensers. The e-tron and ID.4 would each request 125 kW of charging power, so the Kempower system would allocate five 25 kW power modules to each. The LEAF would request 50 kW of charging power, so the Kempower system would allocate two 25 kW power modules to it. The e-Niro would request 77 kW of charging power, so four power modules would be allocated to it. All sixteen power modules would be in use, providing the maximum possible charge power to each vehicle.

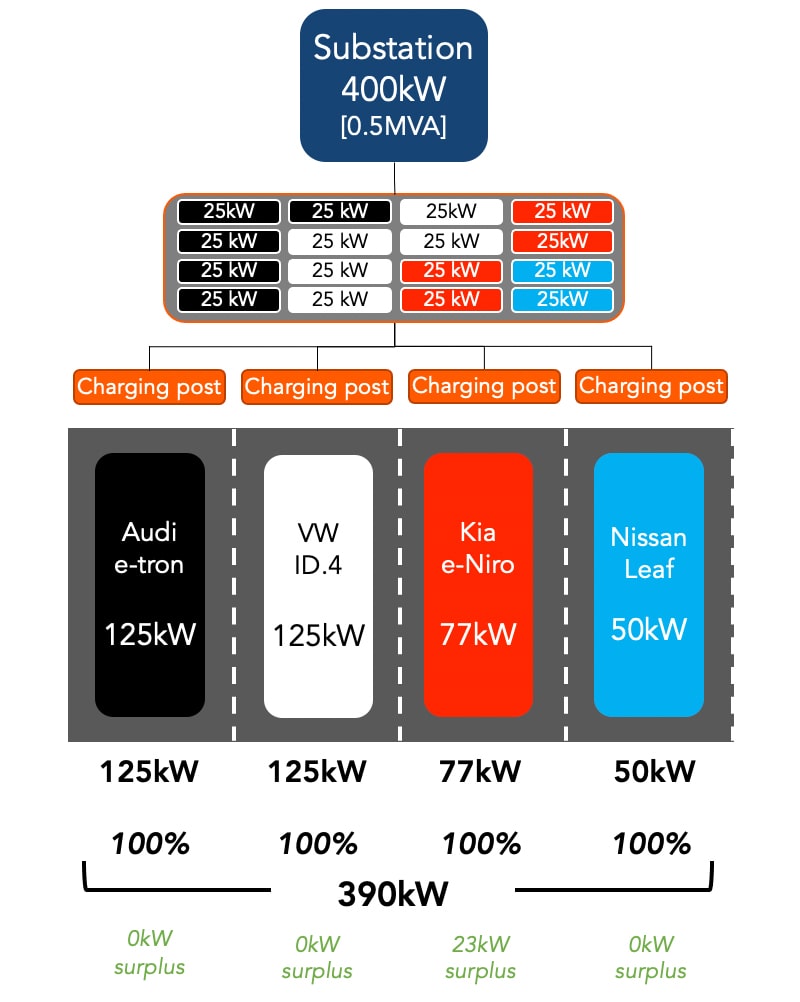

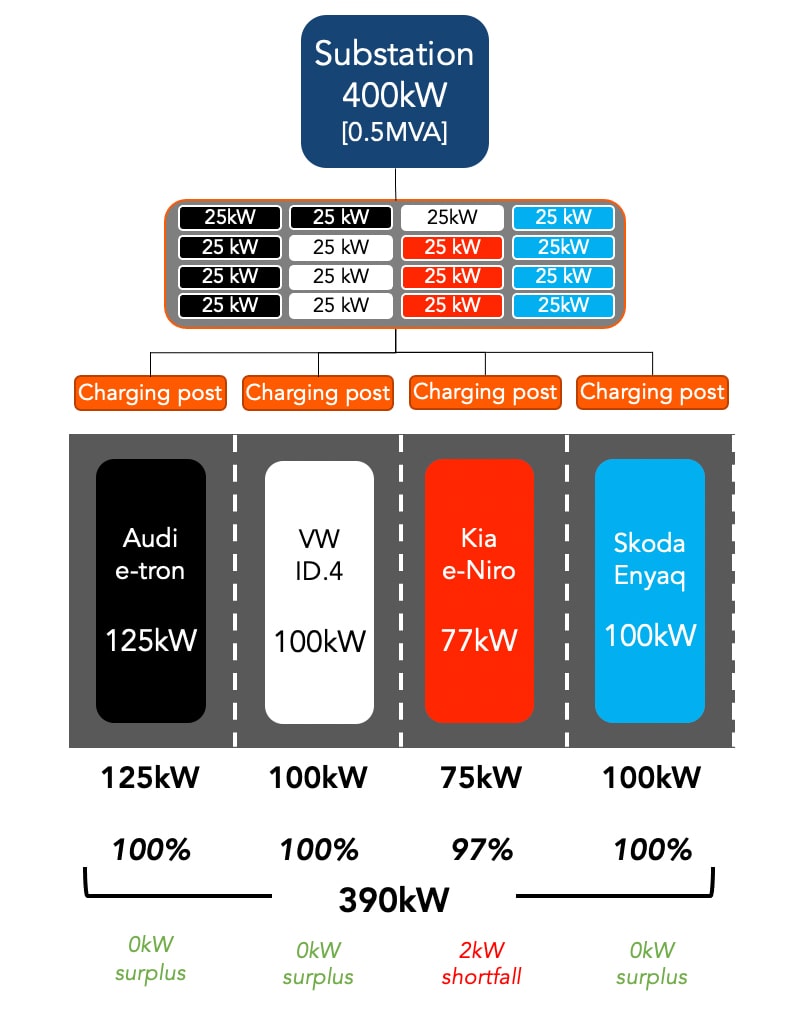

As mentioned previously, the Kempower solution intelligently diverts spare charging power from vehicles that no longer need it, to vehicles that do, via the reallocation of its power modules. This means that if the LEAF was replaced by a Skoda Enyaq iV 60 that can charge at 100 kW, the Kempower system would allocate the LEAF’s two power modules to it, plus the fourth power module from the e-Niro, since the Enyaq would make full use of it whilst the e-Niro is only using 2 kW from it.

Similarly, if the ID.4’s charging power starts to taper off as its battery charges up, and falls to 100 kW, the Kempower system will reassign one of the ID.4’s modules to the Enyaq to give it its full requested charging power and get them back on the road quicker.

What’s more, you can keep track of your charging session whilst you’re away from your car, without needing an app. The Kempower charger has a clear user interface on its screen, which includes a QR code which brings up details of your charging session on your phone. A summary page shows the State of Charge, charge power and total energy added, and if you really want to geek out, there’s a page with a graph that shows how your charge power and State of Charge have varied over time.

So, the Kempower solution allows a greater number of high-power chargers to be installed on a relatively small grid supply, and reacts to charging power tapering off on one vehicle by automatically reassigning it to another vehicle that needs it. Kempower’s hardware has been tried and tested in Norway, the country with the highest EV uptake per capita, which bodes well for it being able to withstand a constant stream of electric vehicles using the charging hub. It goes without say that, as electric vehicle numbers continue to grow, so will the number and size of charging hubs. Kempower’s electron-juggling could easily play out at sites with tens of dispensers and power modules, and vehicles coming and going constantly. Compared to a conventional charging hub, all of this would happen on a comparatively small grid supply and could potentially give you a faster charge too.

Osprey’s first Kempower sites will open in Wolverhampton in mid-September and Banbury in mid-October. Looking at what this tech can do with the grid supply it’s given, I reckon that these sites could easily stake their claim for the title of the smartest high power charging hubs in the UK today.

About the author

Plug Life Consulting was founded by Dr. Euan McTurk, a battery electrochemist who has been working with battery tech and driving electric vehicles since 2009. During that time, Euan has worked with leading battery research groups in Oxford and WMG on projects involving next-generation cell chemistries and the instrumentation of commercial Li-ion cells, and built up a state-of-the-art battery test facility in Edinburgh. He has also launched a YouTube channel, Plug Life Television, which explains complex battery electrochemistry in a way that anyone can understand; demonstrates how it is entirely feasible for entire nations to electrify their transport, and busts several myths about batteries and EVs. In parallel to this, Euan is heavily involved in the electric vehicle sector across the UK, and has regularly been invited to write articles on EVs and battery tech, discuss charging infrastructure roll-out strategies with local authorities and businesses, and present at national conferences and government workshops, resulting in a holistic understanding of electromobility. Plug Life Consulting’s plethora of projects so far include a broad range of technical, strategic and public outreach work within the fields of battery research, energy storage, electric vehicles, transport decarbonisation, charging infrastructure, the battery supply chain and battery recycling.