Professional Documents

Culture Documents

Mixed Mode Solar Dryer

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mixed Mode Solar Dryer

Copyright:

Available Formats

Volume 7, Issue 5, May – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Mixed Mode Solar Dryer

SHUBHAM MHATRE, ATULKUMAR VAGHELA, JITESH MAHESHWARI, PRATHAMESH SURYAWANSHI

guided by Prof. PRAMOD SURYAVANSHI

(Department of Mechanical, Bharati Vidyapeeth College of Engineering, Navi Mumbai)

Abstract:- Mixed mode solar dryer composed of solar chamber and a blower. For dryer to more drying rate, they

collector and a drying chamber. The flat plate collector carried out tests in different conditions.

is the most extensively used solar collector for domestical

and business motive because it is easy and portable III. CONSTRUCTION

format and required lots much less maintenance. The

drying device uses most effective solar energy. The air Solar Air Collector: The Solar Air Collector consists of

allowed in through air inlet is heated up inside the solar components aluminum absorber plate, black glass and for

collector channeled through the drying chamber wherein insulation black paint is applied which helps in decreasing

it is implemented in drying and removing the moisture the heat loss. For absorbing solar energy 1mm thick

content from the agriculture product. This paper gives a aluminum plate is used. The important material that is

format of mixed mode dryer for drying products records used in the dryer is 5mm thick black tinted glass. The

were obtained from the results. casing is made up of sheet metal, which surrounds the

forging components and keeps them free from dust and

I. INTRODUCTION moisture.

Drying Chamber: The drying chamber is constructed of

Solar dryers are devices used to remove moisture in sheet metal with aluminum frame body. It consists of flat

agricultural products or foods by means of heat produced tray with holes for drying the product. To increase heat

from solar energy. Solar dryers are classified as direct, absorption, black coating is applied on the drying

indirect and mixed mode solar dryers. Direct solar dryer chamber. The roof of drying chamber is covered with

uses direct sunlight for drying the food. It consists of a black tinted glass with 5 mm thickness. To control the

drying chamber with transparent roof cover, food tray and convection flow of air an outlet vent is provided to the

air inlet and outlet vents. In an indirect solar dryer, a solar upper end of drying chamber. A door is also provided at

collector is air heated and then passes through the food tray the back of the drying chamber to access tray.

for drying the food. Blower: A blower of 600V with motor speed of 15000rpm

and blowing speed of 80mph is used to pass the hot air

Mixed mode solar is basically a combination of direct

from the solar collector to the drying chamber.

and indirect solar dryers. In mixed mode solar dryer, the

food is dried by the heat generated from direct sunlight and

the heated air from the solar collector. In comparison with

direct and indirect dryers, it is best and significantly gives

better results.

II. LITERATURE REVIEW

Vigneshwaran.T: They proposed the design of the mixed-

mode solar dryer, which consists of a solar collector and a

drying chamber. From its construction, it is concluded that

solar radiation can be used effectively and efficiently to

dry various agricultural products. Also, with the little

region of the dryer, the entire arrangement can be

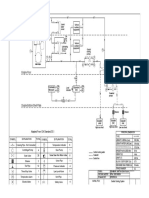

conveyed anyplace without any problem. Fig.1: Working Model of Mixed Mode Solar Dryer

Bukola O. Bolaji: This paper gives the design,

construction and overall performance assessment of a solar

dryer which is used to preserve food. When they were

testing the dryer, they noticed that during most hours of

sunlight, the temperature inside the solar collector and

chamber were much higher than ambient temperature.

Emmanuel Ayua: In this study, from a Horticultural

Innovation Laboratory design they have made a mixed

mode solar dryer. And compared it to a direct solar dryer,

where mixed mode solar dryer had high drying rate. They

made it at low cost and suitable for drying small scale

agricultural products.

Syed Mohammed Shamiq: In this study, they have Fig. 2: Solidworks model of mixed mode solar dryer

developed a solar dryer with a solar collector, a drying

IJISRT22MAY1303 www.ijisrt.com 699

Volume 7, Issue 5, May – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

IV. METHODOLOGY REFERENCES

The procedure of dehydration includes elimination of [1.] Shobhana Singh and Subodh Kumar; Comparative

moisture from the product by heat generated from direct Thermal Performance Study of Indirect and Mixed-

sunlight and heated air from collector. First the product to be mode Solar Dryers; International Journal of

dried is washed, peeled and prepared (if necessary), and Sustainable Energy Development, 2012.

placed on flat-bottomed trays of drying chamber. The direct [2.] Chandrakumar B Pardhi and Jiwanlal L Bhagoria;

sun rays on the solar air collector and drying chamber Development and performance evaluation of mixed-

elevate the drying chamber temperature and the heat mode solar dryer with forced convection; Pardhi and

produced is used to dry the product. The heated product Bhagoria; International Journal of Energy and

offers out water vapor and dries up. Gradually the moist air Environmental Engineering, 2013.

goes up and leaves the drying chamber through the air outlet [3.] Emmanuel Ayua, Violet Mugalavai, James Simon,

on the back of drying chamber. Stephen Weller, Pamela Obura and

NamanNyabinda;Comparison of a mixed modes solar

V. RESULT (GRAPH) dryer to a direct mode solar dryer for African

indigenous vegetable and chili processing: AYUA et

Time Temperature in Normal al, 2016.

(pm) dryer(0C) temperature(0C) [4.] Vigneshwaran.T, Aravindh.A, Jayaraj.R,

2.15 34.7 34.7 Balachandar.B and Arumugam.P;Design of Mixed

2.45 45.9 34.8 Mode Solar Dryer, 2015.

3.15 44.3 35 [5.] Bukola O. Bolaji and Ayoola P. Olalusi;

3.45 43.7 35.3 Performance Evaluation of a Mixed-Mode Solar Dryer,

4.15 44.8 35.2 2008.

4.45 45.9 35.3 [6.] Durga V. N. Lakshmi, PalanisamyMuthukumar,

5.15 44.2 34.6 Jasinta P. Ekka, Prakash K.Nayak and

5.45 41.6 33.3 ApurbaLayek: Performance comparison of mixed

Table1: Reading without blower mode and indirect mode parallel flow forced

convection solar driers for drying Curcuma zedoaria,

Time Temperature in Normal 2019.

(pm) dryer(0C) temperature(0C)

2.15 37 34.2

2.45 41.8 34.4

3.15 43.7 34.7

3.45 46.7 35

4.15 46.9 35.2

4.45 49.3 35.1

5.15 48.6 34.9

5.45 46.9 34.1

Table 2: Reading with blower

From the table 1 and 2readings, it concludes that by

using blower, we get more temperature in the drying

chamber.

By using blower, it gives more efficiency in sunny

days as well as cloudy weather.

VI. CONCLUSION

The portable Mixed Mode Solar Dryer is used to dry

the produce by using the blower and direct sunlight.

By using the blower there is increase in the

temperature inside the drying chamber and product is dried

faster than any regular drying process.

Without blower the temperature doesn’t increases that

much as compared to using blower.

IJISRT22MAY1303 www.ijisrt.com 700

You might also like

- Cummins - ISC8.3 CM2250 (2010-12)Document14 pagesCummins - ISC8.3 CM2250 (2010-12)Diego Lira100% (2)

- Solar D DryerDocument50 pagesSolar D DryerRamnarayan MeenaNo ratings yet

- Cummins KTA19 QSK19 Engine Overhaul PartsDocument10 pagesCummins KTA19 QSK19 Engine Overhaul PartsChen Caroline100% (1)

- Project On Construction of Solar DryerDocument31 pagesProject On Construction of Solar DryerK-Tech SystemsNo ratings yet

- 05 Passion Pro Bsvi Fi Reckoner PDFDocument4 pages05 Passion Pro Bsvi Fi Reckoner PDFZuber SheikhNo ratings yet

- Daftar Harga Eceran Disarankan Yamaha Genuine Parts Efektif 1 November 2022Document1,755 pagesDaftar Harga Eceran Disarankan Yamaha Genuine Parts Efektif 1 November 2022Ronnie LiemNo ratings yet

- Mechanical Design of Smart Solar Tunnel DryerDocument5 pagesMechanical Design of Smart Solar Tunnel DryerashisbhuniyaNo ratings yet

- Application of Solar in Food Dryer-A Literature ReviewDocument5 pagesApplication of Solar in Food Dryer-A Literature ReviewInternational Journal of Innovations in Engineering and ScienceNo ratings yet

- Design, Construction and Evaluation of A Small Scale Solar DryerDocument15 pagesDesign, Construction and Evaluation of A Small Scale Solar DryerDinesh PoudelNo ratings yet

- Self-Cleaning Materials and Surfaces: A Nanotechnology ApproachFrom EverandSelf-Cleaning Materials and Surfaces: A Nanotechnology ApproachWalid A. DaoudRating: 5 out of 5 stars5/5 (1)

- Design and Fabrication of Solar DryerDocument10 pagesDesign and Fabrication of Solar DryerAdeela Umar100% (1)

- Solar Dryer Final ThesisDocument61 pagesSolar Dryer Final ThesisAdeela Umar100% (4)

- Solar Drying Techniques and Performance Analysis: A ReviewDocument5 pagesSolar Drying Techniques and Performance Analysis: A ReviewTekaNo ratings yet

- 6 Ijmperdfeb20196Document8 pages6 Ijmperdfeb20196TJPRC PublicationsNo ratings yet

- Review On Direct, Indirect and Mixed Mode Solar DryerDocument7 pagesReview On Direct, Indirect and Mixed Mode Solar DryerAVES HUSAINYNo ratings yet

- A Comparative Study On Solar Dryer Using External Re - 2022 - Materials Today PDocument8 pagesA Comparative Study On Solar Dryer Using External Re - 2022 - Materials Today PFattah Maulana AlanNo ratings yet

- Performance EnhancementDocument8 pagesPerformance EnhancementPavan BarhateNo ratings yet

- Irjet V5i1241 PDFDocument7 pagesIrjet V5i1241 PDF11751175No ratings yet

- Tunel Solar CocoDocument5 pagesTunel Solar CocoVanNo ratings yet

- Development of Solar Dryer Incorporated With Evacuated Tube CollectorDocument4 pagesDevelopment of Solar Dryer Incorporated With Evacuated Tube Collectormailsk123No ratings yet

- Chilly Tunnel DryingDocument3 pagesChilly Tunnel Dryingdeepakmehta2812No ratings yet

- RETDocument7 pagesRETprathameshdabade15No ratings yet

- Experimental Studies of Drying of Potato Chips With A New Design of Solar DryerDocument5 pagesExperimental Studies of Drying of Potato Chips With A New Design of Solar DryerFrozen ElsaNo ratings yet

- Design and Fabrication of An Indirect Passive Solar Dryer For Drying Tomato SlicesDocument39 pagesDesign and Fabrication of An Indirect Passive Solar Dryer For Drying Tomato SlicesKEHINDE BABALOLANo ratings yet

- Design and Development of Solar Crop Dryer Integrated With Oil BathDocument12 pagesDesign and Development of Solar Crop Dryer Integrated With Oil BathTJPRC PublicationsNo ratings yet

- Performance Analysis of A Solar DryerDocument11 pagesPerformance Analysis of A Solar DryerSerge KewouNo ratings yet

- Performance of A Forced Convection Solar Dryer Integrated With Latent Heat Storage UnitDocument7 pagesPerformance of A Forced Convection Solar Dryer Integrated With Latent Heat Storage UnitVishvesh T SNo ratings yet

- IEEE Technical Paper Assign - A1Document6 pagesIEEE Technical Paper Assign - A1MEA517MIHIR BORANo ratings yet

- A Review Paper On Solar Dryer: 1 Umeshtoshniwal and 2 S.R KaraleDocument7 pagesA Review Paper On Solar Dryer: 1 Umeshtoshniwal and 2 S.R KaraleSams CarigaNo ratings yet

- Performance Evaluation of A Developed Multipurpose Solar DryerDocument8 pagesPerformance Evaluation of A Developed Multipurpose Solar DryerEditor IJTSRDNo ratings yet

- IOT Based Solar Dryer and Irrigation SystemDocument8 pagesIOT Based Solar Dryer and Irrigation SystemIJRASETPublicationsNo ratings yet

- Summary On Solar Greenhouse DryingDocument4 pagesSummary On Solar Greenhouse DryingAnonymous YzKSdaNmskNo ratings yet

- Solar Dryer _VJTI ConferenceDocument10 pagesSolar Dryer _VJTI ConferenceAnil DubeNo ratings yet

- 103 Ijmperdjun2019103Document12 pages103 Ijmperdjun2019103TJPRC PublicationsNo ratings yet

- Prototipe Pengering Tenaga Surya Ditinjau Dari Penggunaan Kolektor Termal Ganda Dan Sistem FotovoltaikDocument8 pagesPrototipe Pengering Tenaga Surya Ditinjau Dari Penggunaan Kolektor Termal Ganda Dan Sistem FotovoltaikIstin SuryaniNo ratings yet

- 10 1016@j Matpr 2020 08 354Document5 pages10 1016@j Matpr 2020 08 354umair ahmadNo ratings yet

- Study of Solar Dryer and Role of Convex Lens in Solar DryerDocument5 pagesStudy of Solar Dryer and Role of Convex Lens in Solar Dryermukesh poundekarNo ratings yet

- Consruction of A Direct Solar Dryer For Perishable Farm ProductsDocument9 pagesConsruction of A Direct Solar Dryer For Perishable Farm ProductsijsretNo ratings yet

- Experimental Studies On Drying Characteristics of Tomato in A Solar Tunnel Greenhouse DryerDocument6 pagesExperimental Studies On Drying Characteristics of Tomato in A Solar Tunnel Greenhouse DryerYared AssefaNo ratings yet

- Comparison of Drying Performance using Sun Dryer, Solar Dryer and Hybrid Solar Dryer for Cassava StarchDocument18 pagesComparison of Drying Performance using Sun Dryer, Solar Dryer and Hybrid Solar Dryer for Cassava Starchdzaki ramadhanNo ratings yet

- Esteem 131Document5 pagesEsteem 131PremSagarJasujaNo ratings yet

- Design Construction and Evaluation of A Small Scale Solar DryerDocument15 pagesDesign Construction and Evaluation of A Small Scale Solar DryerDashaddNo ratings yet

- Drying of Chilli Pepper Using A Solar Dryer With A Back-Up Incinerator Under Makurdi Humid ClimateDocument6 pagesDrying of Chilli Pepper Using A Solar Dryer With A Back-Up Incinerator Under Makurdi Humid ClimateAJER JOURNALNo ratings yet

- DRYERDocument22 pagesDRYERExotic PrasadNo ratings yet

- Journal Pak FarelDocument9 pagesJournal Pak FarelHimsar AmbaritaNo ratings yet

- Development of A Solar Collector For Agricultural Products DryingDocument13 pagesDevelopment of A Solar Collector For Agricultural Products DryingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Review of Hybrid Solar DryersDocument7 pagesReview of Hybrid Solar Dryerssufrotun kimiaNo ratings yet

- Design and Fabrication of a Solar DryerDocument20 pagesDesign and Fabrication of a Solar Dryeryogesh waranNo ratings yet

- Design_and_Analysis_of_a_Solar_Dryer_forDocument7 pagesDesign_and_Analysis_of_a_Solar_Dryer_forYousup AliNo ratings yet

- Design and Development of Solar Air Dryers For RaisinDocument3 pagesDesign and Development of Solar Air Dryers For RaisinMABELNo ratings yet

- 1 PDFDocument8 pages1 PDFmohsin razaNo ratings yet

- Thin Layer Modeling of Corn Grains Using A Hybrid Solar Dryer With LPGDocument6 pagesThin Layer Modeling of Corn Grains Using A Hybrid Solar Dryer With LPGInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design and Development of A Retractable Solar DryerDocument4 pagesDesign and Development of A Retractable Solar DryerAadhil SharifNo ratings yet

- Design and Development of Solar Dryer Cabinet with Thermal Energy StorageDocument5 pagesDesign and Development of Solar Dryer Cabinet with Thermal Energy Storage11751175No ratings yet

- 13 Ijasrdec201813Document6 pages13 Ijasrdec201813TJPRC PublicationsNo ratings yet

- Desain FurnaceDocument15 pagesDesain FurnaceWiwin LatifahNo ratings yet

- Design Development and Performance Evaluation of Indirect Forced Convection Solar Dryer For GrapesDocument4 pagesDesign Development and Performance Evaluation of Indirect Forced Convection Solar Dryer For GrapesAVESAHEMADNo ratings yet

- Design Construction and Evaluation of A Small Scale Solar DryerDocument15 pagesDesign Construction and Evaluation of A Small Scale Solar DryerzahreldinelaliNo ratings yet

- A Review On Solar Drying Techniques and Solar Greenhouse DryerDocument8 pagesA Review On Solar Drying Techniques and Solar Greenhouse DryerYared AssefaNo ratings yet

- Đây-Evaluation of operational parameters for drying shrimps in a cabinetDocument9 pagesĐây-Evaluation of operational parameters for drying shrimps in a cabinettranvothanhkhai2003No ratings yet

- Experimental study of regenerative desiccant integrated solar dryer with and without reflective mirrorDocument9 pagesExperimental study of regenerative desiccant integrated solar dryer with and without reflective mirrorjoanamb96No ratings yet

- Design and Development of Solar Air Dryer For Drying of Apricot For Ladhak RegionDocument10 pagesDesign and Development of Solar Air Dryer For Drying of Apricot For Ladhak RegionkolkNo ratings yet

- Sustainability 14 05558 v2Document13 pagesSustainability 14 05558 v2Ahamed Saleel CNo ratings yet

- Cold Inflow-Free Solar Chimney: Design and ApplicationsFrom EverandCold Inflow-Free Solar Chimney: Design and ApplicationsMd. Mizanur RahmanNo ratings yet

- An Analysis on Mental Health Issues among IndividualsDocument6 pagesAn Analysis on Mental Health Issues among IndividualsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Harnessing Open Innovation for Translating Global Languages into Indian LanuagesDocument7 pagesHarnessing Open Innovation for Translating Global Languages into Indian LanuagesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Diabetic Retinopathy Stage Detection Using CNN and Inception V3Document9 pagesDiabetic Retinopathy Stage Detection Using CNN and Inception V3International Journal of Innovative Science and Research TechnologyNo ratings yet

- Investigating Factors Influencing Employee Absenteeism: A Case Study of Secondary Schools in MuscatDocument16 pagesInvestigating Factors Influencing Employee Absenteeism: A Case Study of Secondary Schools in MuscatInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Exploring the Molecular Docking Interactions between the Polyherbal Formulation Ibadhychooranam and Human Aldose Reductase Enzyme as a Novel Approach for Investigating its Potential Efficacy in Management of CataractDocument7 pagesExploring the Molecular Docking Interactions between the Polyherbal Formulation Ibadhychooranam and Human Aldose Reductase Enzyme as a Novel Approach for Investigating its Potential Efficacy in Management of CataractInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Making of Object Recognition Eyeglasses for the Visually Impaired using Image AIDocument6 pagesThe Making of Object Recognition Eyeglasses for the Visually Impaired using Image AIInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Relationship between Teacher Reflective Practice and Students Engagement in the Public Elementary SchoolDocument31 pagesThe Relationship between Teacher Reflective Practice and Students Engagement in the Public Elementary SchoolInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Dense Wavelength Division Multiplexing (DWDM) in IT Networks: A Leap Beyond Synchronous Digital Hierarchy (SDH)Document2 pagesDense Wavelength Division Multiplexing (DWDM) in IT Networks: A Leap Beyond Synchronous Digital Hierarchy (SDH)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Comparatively Design and Analyze Elevated Rectangular Water Reservoir with and without Bracing for Different Stagging HeightDocument4 pagesComparatively Design and Analyze Elevated Rectangular Water Reservoir with and without Bracing for Different Stagging HeightInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Impact of Digital Marketing Dimensions on Customer SatisfactionDocument6 pagesThe Impact of Digital Marketing Dimensions on Customer SatisfactionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Electro-Optics Properties of Intact Cocoa Beans based on Near Infrared TechnologyDocument7 pagesElectro-Optics Properties of Intact Cocoa Beans based on Near Infrared TechnologyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Formulation and Evaluation of Poly Herbal Body ScrubDocument6 pagesFormulation and Evaluation of Poly Herbal Body ScrubInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Advancing Healthcare Predictions: Harnessing Machine Learning for Accurate Health Index PrognosisDocument8 pagesAdvancing Healthcare Predictions: Harnessing Machine Learning for Accurate Health Index PrognosisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Utilization of Date Palm (Phoenix dactylifera) Leaf Fiber as a Main Component in Making an Improvised Water FilterDocument11 pagesThe Utilization of Date Palm (Phoenix dactylifera) Leaf Fiber as a Main Component in Making an Improvised Water FilterInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Cyberbullying: Legal and Ethical Implications, Challenges and Opportunities for Policy DevelopmentDocument7 pagesCyberbullying: Legal and Ethical Implications, Challenges and Opportunities for Policy DevelopmentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Auto Encoder Driven Hybrid Pipelines for Image Deblurring using NAFNETDocument6 pagesAuto Encoder Driven Hybrid Pipelines for Image Deblurring using NAFNETInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Terracing as an Old-Style Scheme of Soil Water Preservation in Djingliya-Mandara Mountains- CameroonDocument14 pagesTerracing as an Old-Style Scheme of Soil Water Preservation in Djingliya-Mandara Mountains- CameroonInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Survey of the Plastic Waste used in Paving BlocksDocument4 pagesA Survey of the Plastic Waste used in Paving BlocksInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Hepatic Portovenous Gas in a Young MaleDocument2 pagesHepatic Portovenous Gas in a Young MaleInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design, Development and Evaluation of Methi-Shikakai Herbal ShampooDocument8 pagesDesign, Development and Evaluation of Methi-Shikakai Herbal ShampooInternational Journal of Innovative Science and Research Technology100% (3)

- Explorning the Role of Machine Learning in Enhancing Cloud SecurityDocument5 pagesExplorning the Role of Machine Learning in Enhancing Cloud SecurityInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Review: Pink Eye Outbreak in IndiaDocument3 pagesA Review: Pink Eye Outbreak in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Automatic Power Factor ControllerDocument4 pagesAutomatic Power Factor ControllerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Review of Biomechanics in Footwear Design and Development: An Exploration of Key Concepts and InnovationsDocument5 pagesReview of Biomechanics in Footwear Design and Development: An Exploration of Key Concepts and InnovationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mobile Distractions among Adolescents: Impact on Learning in the Aftermath of COVID-19 in IndiaDocument2 pagesMobile Distractions among Adolescents: Impact on Learning in the Aftermath of COVID-19 in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Studying the Situation and Proposing Some Basic Solutions to Improve Psychological Harmony Between Managerial Staff and Students of Medical Universities in Hanoi AreaDocument5 pagesStudying the Situation and Proposing Some Basic Solutions to Improve Psychological Harmony Between Managerial Staff and Students of Medical Universities in Hanoi AreaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Navigating Digitalization: AHP Insights for SMEs' Strategic TransformationDocument11 pagesNavigating Digitalization: AHP Insights for SMEs' Strategic TransformationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Drug Dosage Control System Using Reinforcement LearningDocument8 pagesDrug Dosage Control System Using Reinforcement LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Effect of Time Variables as Predictors of Senior Secondary School Students' Mathematical Performance Department of Mathematics Education Freetown PolytechnicDocument7 pagesThe Effect of Time Variables as Predictors of Senior Secondary School Students' Mathematical Performance Department of Mathematics Education Freetown PolytechnicInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Formation of New Technology in Automated Highway System in Peripheral HighwayDocument6 pagesFormation of New Technology in Automated Highway System in Peripheral HighwayInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 20 Years Power Plant GATE, IES & IAS Questions with AnswersDocument48 pages20 Years Power Plant GATE, IES & IAS Questions with Answerselajchet senniNo ratings yet

- Solar Powered Intelligent Car Cabin Ventilation System - OkDocument16 pagesSolar Powered Intelligent Car Cabin Ventilation System - Okkrushna NikamNo ratings yet

- Aya 079 eDocument36 pagesAya 079 eWidjaja HarijaniNo ratings yet

- AC Resonant Test System: WRVG 1.5/680 GDocument4 pagesAC Resonant Test System: WRVG 1.5/680 GMauricio AgudeloNo ratings yet

- Mock Test No 7Document9 pagesMock Test No 7Phuong AnhNo ratings yet

- Miller Insulation Checker Operating Instructions (MAN420)Document3 pagesMiller Insulation Checker Operating Instructions (MAN420)uaiphonNo ratings yet

- Grundfos SOLOLIFT2 Sewage Lifting StationsDocument2 pagesGrundfos SOLOLIFT2 Sewage Lifting Stationsacodr83No ratings yet

- Kidde Engineered Fire Suppression System: 3-Way Directional Ball Valve Data SheetDocument10 pagesKidde Engineered Fire Suppression System: 3-Way Directional Ball Valve Data SheetEmad SalamaNo ratings yet

- Aero Thermodynamics Analysis and Design of A Rolling Piston EngineDocument59 pagesAero Thermodynamics Analysis and Design of A Rolling Piston EngineraviNo ratings yet

- Spec Sheet SES TLED Lamp PDFDocument3 pagesSpec Sheet SES TLED Lamp PDFEvan MerkelNo ratings yet

- Evopact SF Sf1000000x1fxDocument2 pagesEvopact SF Sf1000000x1fxEric Fabián Sánchez UmañaNo ratings yet

- Est Micro ProjectDocument15 pagesEst Micro ProjectDictator Aditya Acharya0% (1)

- OVP Test ProceduresDocument3 pagesOVP Test Proceduresحجت زارعNo ratings yet

- 6 Wheeler & Trucks Engine OhDocument12 pages6 Wheeler & Trucks Engine Ohhajj basitNo ratings yet

- D09 - Veshnyakov RussaDocument17 pagesD09 - Veshnyakov RussaLazarescu ElenaNo ratings yet

- Radioactivity Required LabDocument12 pagesRadioactivity Required LabKIANNA FLORESNo ratings yet

- Em-Vam - Gvju (Edus711116b) 01-04-2020Document32 pagesEm-Vam - Gvju (Edus711116b) 01-04-2020CharbelNo ratings yet

- Chromagen Installation Technical ManualDocument80 pagesChromagen Installation Technical ManualNana AkwaboahNo ratings yet

- Water Four GasDocument115 pagesWater Four GasnikNo ratings yet

- Miftah Dhia Falah - Cooling System PnIDDocument1 pageMiftah Dhia Falah - Cooling System PnIDRaja Fatah Satrio AbimanyuNo ratings yet

- Compact Pressure Switches: Series 9671X/9681X/9692X Series 9671X/9681X/9692XDocument3 pagesCompact Pressure Switches: Series 9671X/9681X/9692X Series 9671X/9681X/9692XsimunNo ratings yet

- VENDOR of TIAL Product - PT. Agung SentosaDocument23 pagesVENDOR of TIAL Product - PT. Agung Sentosahaykal azkaNo ratings yet

- PaintingsDocument8 pagesPaintingsKs SenthilKumarNo ratings yet

- 352 KW Doosan Generator D440 IvDocument5 pages352 KW Doosan Generator D440 IvRodolfoGarciaNo ratings yet

- Unit 9 - Week 7: Introduction To Gas Turbines: Assignment 07Document5 pagesUnit 9 - Week 7: Introduction To Gas Turbines: Assignment 07Saurabh ManralNo ratings yet

- Unit 1 AssignmentDocument2 pagesUnit 1 Assignmentprakul varshneyNo ratings yet