Bioabsorbable Stents: Are Newest Innovations In the Field of Medical Technology

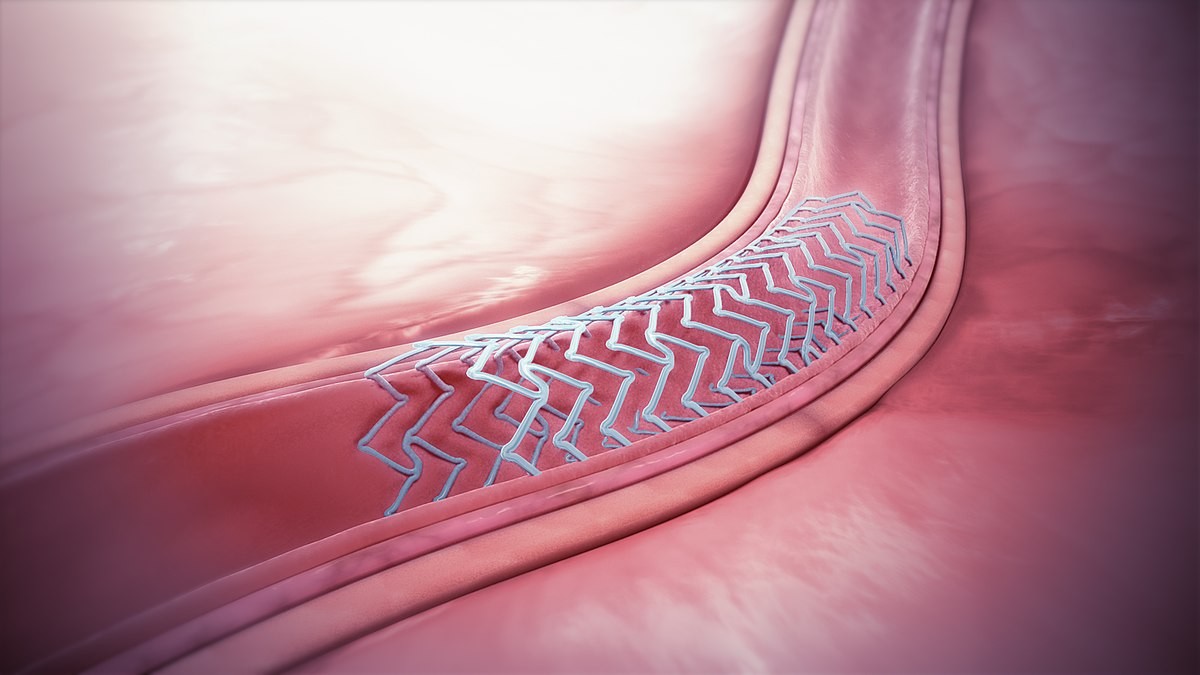

A stent is a metal object that's either inserted into an artery or other internal urinary duct to expand it to stop a blockage or facilitate passage of a fluid. Traditionally, they are constructed with flexible metal mesh and stay within the body until removed via subsequent surgical intervention or through recovery. With the utilization of bioabsorbable polymers, a new class of stents called Bioabsorbable Stents have now been developed. This class of stents doesn't use metal mesh but has a firm core full of a liquid to counteract urinary stream pressures and thus is suited to external applications.

An important benefit of this sort of stent when compared with traditional metal or glass-based stents is its use of easily available materials. In traditional stents, metal and glass are generally required. Other metals such as for example tin, copper, and even asbestos are also used. Another major benefit of Bioabsorbable Stents is that the material could be changed and reused over time. The recyclability of PVB-stented polymeric membranes is one step more than that of conventional materials like polyurethane or magnesium-based scaffolds.

The key disadvantage of those polymeric scaffolds, compared to materials such as for example metal and glass-based ones, is that the scaffold's core is a liquid and is subject to wear and tear consequently of experience of air and moisture. This makes the dissolving process slower with a better possibility of structural failures. Another disadvantage is that the scaffold must have its inner surface manufactured from a specific polymer. Polymer-based scaffolds are easier molded into different shapes while maintaining their core function. This causes it to be easier to obtain a regular thickness through the entire material.

In contrast to conventional metal and glass-based scaffolds, Bioabsorbable Stents are not subject to wear and tear and corrosion. They are manufactured from materials that can't be degraded by air and water. This means that once installed, the scaffold can stay as-is for an extended amount of time. Also, unlike conventional drug-eluting stents, the outer surface of this sort of scaffold doesn't need to be manufactured from a specific polymer. This feature is another contributing aspect in its easy application and versatility. It can be used to cover wounds in addition to prevent blood clots.

In addition to being flexible and durable, Bioabsorbable Stents also have another advantage that sets them besides conventional scaffolds: they've a low-cost effect. Unlike conventional metal and glass-based scaffolds, which cost roughly 3 x a lot more than cellulose-based scaffolds, and which require significant investment before installation, the application of a these stent requires almost no upfront preparation or investment. All that's needed is its application on the wound site. After the scaffold has already been installed, all that remains is maintenance, including occasional replacement of magnesium-based scaffolds. Since it does not degrade with experience of air and water, the scaffold can also be maintenance-free.

Since the introduction of bioresorbable scaffolds, manufacturers have now been able to lessen the costs of scaffolding installations. For example, unlike drug-eluting and polyethylene-based (PE) scaffolds, which are heavier and more expensive, bioresorbable scaffolds weigh about half of a pound, making them easy to transport and less costly for manufacturers to produce. In addition they offer patients a chance to experience their products before undergoing an important medical procedure or surgery, and to use different applications, too. Thus, bioabsorbable stents have now been found to be beneficial in several medical circumstances.