Professional Documents

Culture Documents

Group Acceptance Sampling Plan For Truncated Life Test Using Generalized Exponential-Poisson Distribution

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Group Acceptance Sampling Plan For Truncated Life Test Using Generalized Exponential-Poisson Distribution

Copyright:

Available Formats

Volume 7, Issue 4, April – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Group Acceptance Sampling Plan for Truncated

Life Test using Generalized

Exponential-Poisson Distribution

Dr. V. Kaviyarasu1and S. Sivasankari2

1

Assistant Professor and 2 Research scholar

Department of Statistics, Bharathiar University,

Coimbatore-641046,Tamilnadu

Abstract:- A Group Acceptance Sampling Plan (GASP) observing the lifetime of the products until it fails is not

is designedto study the truncated life testplan when the possible. The truncated life test is intentionally used to save

lifetime of an item follows a new compound distribution the time and cost of the experiment in such a way that life

called as Generalized Exponential-Poisson (GEP). In this test can be studied at the specified time period.

article the design parameters are developed for the

group size, its acceptance numbers, OC curve, minimum In an attribute single sampling planbased on the

number of groups are determined through the specified truncated life testa decision of acceptance or rejection of the

consumer’s confidence level and test termination ratio. lot is made based on the single sample which is the

Two points on the OC curve approach is incorporated to traditional procedure in sentencing the lot. Epstein. B (1954)

design the proposed plan. The OC values are calculated discussed truncated life test in the exponential case. Goode

when the ratio of specified average life and the actual H.P and Kao J.H.K (1961) have studied sampling plan based

average life is given. The minimum mean ratio for the on the weibull distribution. Balamuarali S. and Lee S.H

proposed plan are determined at the fixed producer’s (2006) discussed variable sampling plans for Weibull

risk. The obtained plan parameters are illustrated with distribution under sudden death testing. Kaviyarasu and

areal time example with the simulation study which are fawaz (2007) has studied reliability sampling plan to ensure

exhibited in the tables. percentiles through Weibull Poisson Distribution.

Kaviyarasu, V. and Sivasankari, S. (2020) studied the Single

Keywords:- Generalized Exponential-Poisson distribution, sampling plan for life testing under the Generalized

consumer’s confidence level, producer’s risk, operating Exponential-Poisson Distribution. Every single item in the

characteristic function, truncated life test. sampling units are required single tester however in practice

a tester may accommodate multiple number of items

I. INTRODUCTION simultaneously hence it saves more time and the cost of the

experiment. Here the items in a tester can be regarded as a

In the competitive global market, quality product group and the number of items in the group is called as

always seeks more attention and demand to meet the group size such as study is called as Group Acceptance

standards prescribed by the manufactures. In industry Sampling Plan (GASP). In this method many items can be

outgoing or incoming products are widely inspected to tested on the basis of few items are tested from the lot size

control the quality of the products which are essential of infinite. Hence this GASP elevate the ordinary plan to

activities in industries. Statistical quality control may inspect many items with multiple tester. Also it improves the

categorized into process control and product control. precision of the testing because various sampling units are

Product control plays a vital role when the product is in distributed to multiple testers. In a life test experiment, a

finished mode and helps to identify the reliable product and sample of size n is tested from a lot of products is put on the

eliminate the manufacturing errors.The statistical techniques test when the corresponding acceptance number is fixed

are usually employed to remove the defective products in with the test assigned time. Probability of rejecting a good

the production process as an offline product control lot is called the producer’s risk and probability of accepting

techniques at any stage of the manufacturing process as an a bad lot is called the consumer’s risk. Here the confidence

incoming raw materials, semi-finished products or a finished level is p* then the consumer risk will be 1-p*. The main

products can be tested.Product control is equally important objective of any acceptance sampling plan procedure is to

techniques however sampling plans for attributes and reduce both the risk simultaneously.

variables are widely studied, however sampling plan by

attributes is easy to perform in industrial shop floor Therefore many researchers prefers the GASP than any

conditions. Acceptance sampling plan is one of the other plans and have done their researchwith various

important techniques adopted in quality control towards distributions such as Aslam and Jun (2009)designed the

inspection and testing the sampling units in which decision group acceptance sampling plans based on the truncated life

about the lot can be made. In the acceptance sampling test when the life time of products follows an Gamma

procedure the life test plan is carried out when the quality Distribution and Weibull distributions. Rao (2011)

characteristics of the product is defined by its lifetime. In introduced a hybrid group acceptance sampling plans for

particular, truncated life test is adopted at which the test will lifetimes based on generalized exponential distribution and

terminated at a certain point of time in the sense that log logistic distributions. Aslam et al.(2010) introduced an

IJISRT22APR238 www.ijisrt.com 999

Volume 7, Issue 4, April – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

improved group sampling plan based on time truncated life increasing and also upside-down bathtub shaped model.

tests. Kaviyarasu and Suresh (2011)proposed a new plan and These applications of the proposed distribution can be seen

designated as quick switching multiple repetitive group the toys and crafts manufacturing sectors are widely used.

sampling plan of type QSMRGSP-1 in which disposition of

lot is determined on the basis of normal and tightened GEP distribution characterized by the parameter α (>0)

sampling schemes. Sudamani Ramaswamy and and the random sample 𝑌1 . . . . . . . 𝑌∝ from the EP distribution.

Sutharani(2012) designed Weighted Group Sampling Plan So that X = max{𝑌𝑖 }α𝑖=1 is GEP distributed. Hence this model

Based on Truncated Life Tests under various distribution can be applicable for the maximum lifetimes of EP random

using Minimum Angle Method. Muhammad Aslam et al. samples. GEP is more suitable distribution for the physical

(2013)proposed a multiple state Repetitive Group Sampling interpretation. If the n components are connected in a

plan by considering the processloss. Aslam et al. (2015) parallel system, the lifetimes of the components are

proposed two stage group acceptance sampling plan for half identically and independently GEP distributed random

normal percentiles. Rosaiah et al. (2016) developed a group variables. Also the whole system lifetime follows the GEP

acceptance sampling plan for truncated life tests when the law.The Probability density function of GEP is

lifetime of items follows the Type-II generalized log logistic 𝛼𝜆𝛽

distribution (TGLLD). f(x;𝜃) = {1 −

(1−𝑒 −𝜆 )𝛼

−𝜆+𝜆 exp(−𝛽𝑥) }𝛼−1 −𝜆−𝛽𝑥+𝜆 exp (−𝛽𝑥)

II. OPERATING PROCEDURE 𝑒 𝑒 -----(1)

Here our interest in determining the number of group’s The Cumulative Distribution Function of the GEP is

‘g’ with the various values of acceptance number c and the given as

test termination time t0 are assumed to be specified. The 𝛼

1−𝑒 −λ+λexp(−βx)

operating procedure of GASP is as follows, 𝐹(𝑥; 𝜃) = ( )

1−𝑒 −λ

Step 1: Select a random sample of size n from a lot of size -----(2)

N and assign r number of units to each of g groups, so that

n= r*g Where θ (>0) = (α, β, λ), α is the shape parameter, β is

Step 2: Fix the acceptance number c and the experiment the scale parameter of the Exponential distribution and λ is

time t0. the Poisson parameter. When α = 1, Generalized

Step 3: Perform the experiment for the g groups Exponential Poisson reduces to Exponential Poisson

simultaneously and record the number of failures for each distribution. When α = 1 and λ→ 0, Exponential Poisson

group till the specified time t0 𝑡

reduces Exponential distribution with parameter β. Let x =β2

Step 4: Accept the lot if the number of failures from all the

groups together is smaller than or equal to c. , Then consider the CDF of the mean life product quality of

GEP distribution becomes,

Step 5: Reject the lot whenever number of failures more

than c as well as terminate the test before time t0. 𝑡

−λ+λexp(− )

𝛼

1−𝑒 β

The quality of the product is tested with GASP on the 𝐹(𝑥; 𝜃) = ( 1−𝑒 −λ

)

basis of the above procedure when few items are taken from t, λ,α, β > 0 -----(3)

an infinite lot is tested. Here, Group Acceptance Sampling

Plan (GASP) is studied under the proposed probability IV. TWO POINT ON THE OPERATING

distribution on the truncated life test under percentile as a CHARACTERISTIC CURVE

quality parameter when the life time of a product assumed to

follow the Generalized Exponential-Poisson distribution. The two important risks involved in the acceptance

sampling procedure is well known as producer’s risk and the

III. GENERALIZED EXPONENTIAL-POISSON consumer’s risk. The risk happening in the inspection

DISTRIBUTION procedures which exclusively depends with making of

Most of the probabilistic models are studied to describe wrong decision such as rejecting the good lot and accepting

the life time of data follows a certain life time distribution. the bad lot. Hence rejecting the good lot due to inherent

Here the failure time of an inspecting product may follows a nature of random sampling is the producer’s risk and

life time distribution is modelled using a statistical accepting the bad quality lot due to inherent nature of the

distribution. Kus(2007) introduced a two parameter random sample is known as consumer’s risk. Both the risk

distribution called Exponential-Poisson distribution. Later, have to be kept minimum for producing the reliable product.

Wagner Barreto-Souza and Francisco Cribari-Neto (2009) Hence it is considering the two levels Acceptable Reliability

derived a new distribution with three parameters known as Level (ARL) and Limiting Reliability Level (LRL) to

Generalized Exponential-Poisson (GEP) Distribution. This minimize the risks, which are obtained through Producer’

new distribution is a compounding of an exponential and a confidence level (1-α) and the consumer’s level β. The

Poisson distribution. In reality the failure item of a reliability sampling plan is an efficient one when both the

manufacturing product may not follow a particular risks are under control. Here, α ≤ 0.05 and β ≤ 0.10. Thus

distribution which may vary on the design parameters the probability of acceptance can be obtained for the

regardless on the underlying statistical distribution. The incoming quality using the following inequality,

failure rate of the distribution can be decreasing or 𝐿(𝑝1 ) ≥ 1 − 𝛼and𝐿(𝑝2 ) ≤ 𝛽

IJISRT22APR238 www.ijisrt.com 1000

Volume 7, Issue 4, April – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

distribution function of GEP in terms of incoming quality of

Where 𝑝1 is the ARL and 𝑝2 is the LRL. The value of 𝑡⁄ and𝛽⁄ Such that

𝑝1 and 𝑝2 obtained through 𝑝 = 𝐹 (𝑡⁄𝛽 ∗ 1⁄𝑑 ) When 𝛽0 𝛽0

0

𝛽 𝛽 𝛽

𝑑1 = ⁄𝛽 >1 and𝑑2 = ⁄𝛽 =1 respectively. When the 𝑝 = 𝐹 (𝑡⁄𝛽 ∗ 1⁄𝑑 ) Where 𝑑= ⁄𝛽

0 0 0 0

actual mean lifetime of the product is similar to the specified ……………(6)

mean lifetime, i.e., the lot quality is good enough to accept

𝛽 Probability of rejecting a lot even if the lot quality is

at ⁄𝛽 = 1 there is no chance of arising the risk. The

0 good ie.,𝛽≥ 𝛽0 , the actual mean lifetime is greater than the

proposed approach of finding the design parameters is to specified mean lifetime is mentioned as producer’s risk.

satisfy the above two inequalities for the operating Hence to reduce the producer’s risk, one must be interested

characteristic function L (p)simultaneously. 𝛽

in finding the value of ⁄𝛽 in designing the GASP (rg,

0

V. DESIGNING OPTIMAL PLAN PARAMETERS c,𝑡⁄𝛽 )corresponding to P*. This smallest value of the ratio

0

The sampling plan of Group Acceptance Sampling 𝛽

⁄𝛽 can be determined under the condition that producer’s

Plan is exemplified by (rg, c, 𝑡⁄𝛽 ).For the practical use of 0

risk which is kept under 0.05. Thus the proposed life testing

0

the sampling plancan be obtaining with the smallest positive sampling plan is studied under

integer n =(r*g). The group acceptance sampling plan is

reduced to single sampling plan when the group size r = 1. L(p) ≥ 1-α ----------(7)

The designing plan parameters of the proposed sampling

𝛽

plan, minimum number of groups are determined with the Therefore the minimum mean ratio ⁄𝛽 of truncated

0

assumption that the lot size is large enough to use the life test plan can be evaluated by satisfying the following

binomial distribution. The quality of the item is usually inequality,

represented by its true life time such as mean life, median 𝑐

life and percentile life. It is obtained for the given values of 𝑟𝑔 𝑖

∑( ) 𝑝 (1 − 𝑝)𝑟𝑔−𝑖

test termination ratio 𝑡⁄𝛽 andthe acceptance number c at the 𝑖=0

𝑖

0

specified consumer’s confidence level by using the ≥ 0.95 … … … … … … (8)

following non-linear constraint under the percentile life is

𝛽0

studied, wherep = F (𝑡⁄𝛽 . ⁄𝛽 )

0

𝑟𝑔

𝐿(𝑝1 ) = ∑𝑐𝑖=0 ( ) 𝑝1𝑖 (1 − 𝑝1 )𝑟𝑔−𝑖 ≤ 1 − VI. DESCRIPTION OF TABLE VALUES

𝑖

𝑃∗ … … … … . (4)

Step 1: Fix the parameters of GEP distribution α = 2, λ=2

Where 𝑝1 = 𝐹(𝑥; 𝜃) is the and the test termination ratio

𝑡⁄ = 0.5, 0.6, 0.7, 0.8, 0.9,1.0

𝑡 𝛼 𝛽 0

−λ+λexp(− )

𝐹(𝑥; 𝜃) = (

1−𝑒 β

) t, λ,α, β > 0 Step 2: Obtain 𝑝values in terms of the given

1−𝑒 −λ 𝑡⁄ mentioned in (3)

𝛽 0

Step 3: Determine the smallest positive integer g by

Where𝑝1 is the probability of failure of an item at time

applying the condition that

t.𝑝1 depends only on𝑡⁄𝛽 Therefore the minimum group size 𝑐

0 𝑟𝑔

determined using the search procedure for the various given 𝐿(𝑝) = ∑ ( ) 𝑝1𝑖 (1 − 𝑝1 )𝑟𝑔−𝑖 ≤ 1 − 𝑃∗

𝑖

values of 𝑃∗ , c and 𝑡⁄𝛽 and tabulated. The minimum 𝑖=0

0

group size is determined while satisfying both the consumer Specify the appropriate consumer’s confidence levels

and the producer by fixing the risk at certain level such as 0.75, 0.90, 0.95, 0.99 and the acceptance number 0 to 4.

𝑃∗ = 0.75, 0.90, 0.95, 0.99. With the assumption of lot size is large enough to the need

of binomial distribution in finding the success or failure item

𝐿(𝑝) in the truncated life test plan and using the search procedure,

𝑐

𝑟𝑔 the minimum group size is obtained for r =2 and exhibited in

= ∑ ( ) 𝑝𝑖 (1 the Table-1

𝑖

𝑖=0

Step 4: The OC values for the given incoming product

− 𝑝)𝑟𝑔−𝑖 … … … … (5) quality d is evaluated as

𝑐

The probability of acceptance of the GASP can be 𝑟𝑔

found out using (5) only when both the consumer’s and the 𝐿(𝑝) = ∑ ( ) 𝑝𝑖 (1 − 𝑝)𝑟𝑔−𝑖

𝑖

𝑖=0

producer’ risk are used in simulation process. The two

points on the operating characteristic curve are the deciding Where 𝑝 is the cumulative distribution function in

factors in sentencing the lot to meet the necessity of both the 𝛽

producer and the consumer. Where𝑝 is the cumulative terms of incoming quality of 𝑡⁄𝛽 and ⁄𝛽 Such that

0 0

IJISRT22APR238 www.ijisrt.com 1001

Volume 7, Issue 4, April – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

𝛽 confidence levels 0.75, 0.90, 0.95, 0.99 and exhibited in the

o 𝑝 = 𝐹 (𝑡⁄𝛽 ∗ 1⁄𝑑) Where 𝑑 = ⁄𝛽

0 0 Table-3.

Step 5: Fix the ratio 𝑡⁄𝛽 = 0.5, 0.6, 0.7, 0.8, 0.9, 1 and

0

𝛽 VII. OC CURVE

⁄𝛽 = 1.0, 1.5, 2.0, 2.5, 3.0, 3.5, 4.0 and 4.5 substitute in

0

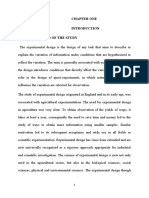

For the specified test termination ratio t/t 0with q = 0.8

(6) and find 𝑝 values. Through the value of incoming

and the acceptance number c =0 for the consumer’s

quality 𝑝, the probability of acceptance for each 𝑝 value

confidence level 0.99, the percentile lifetime plan is

can be obtained from (5) and presented in the Table-2

obtained from the Table-1, the minimum number of groups

Step 6: The minimum ratio is obtained by using the

𝛽 g = 3. Hence the plan is executed as (3, 0 and 0.8) with the

inequality (7). For the given values of 𝑡⁄𝛽 , ⁄𝛽 , n = r * minimum percentile ratio is 7.3340 from Table-3. From this

0 0

g also the acceptance number c. obtained plan parameters one can arrive at the conclusion

that the product will have the percentile life of 7 times of the

Here one can obtain the minimum mean ratio which specified percentile life of 1000 hours with the lot

can assures that the producer’s risk will not be more than acceptance 0.99.The OC curve of the proposed plan (n= 4*3

0.05 for the proposed truncated life test plan. The minimum = 12, c= 0and 𝒕⁄𝜷 = 0.8)is shown in the following figure.

𝟎

mean ratio is obtained for the specified consumer’s

OC curve for GASP

1

0.9

0.8

0.7

0.6

L(p)

0.5

0.4

0.3

0.2

0.1

0

1 1.5 2 2.5 3 3.5 4 4.5 5

dq

Fig. 1: OC curve of the (n= 4*3 = 12, c= 0and 𝒕⁄𝜷 = 0.8)

𝟎

The probability of acceptance can be regarded as a function of the deviation for the specified values are given to test the

percentile life. The function is called the Operating Characteristics curve of the proposed sampling plan is given. From this one

can obtain the minimum sample size and interested to find the probability of lot acceptance when the quality of the item is

sufficiently good under the study.

VIII. EXAMPLE

Consider an electronic toys manufacturing company Thus the proposed plan is performed as the testing with

wants to adopt the proposed sampling plan for life testing 6 tester (group) with 2 items in each group simultaneously at

the electronic toys. Suppose that the quality testing engineer the exact consumer’s risk 𝛽 = 0.0096. Accept the lot if no

wants to study the lifetime of a product which may follows more than 1 failure in each of all the groups occur or else

the Generalized Exponential-Poisson distribution, it is reject the lot. For this proposed electronic toy testing a

desired to design the GASP to test the actual lifetime is sample size of 12 items are tested with g=6 and r=2 (2*6, 1,

greater than 1000 hours when the test terminated at 800 0.8) with 12 items are tested and one may interested in

hours and 2 items on each tester with allowed number of finding the probability of acceptance for the method from

failures for each group is 2. It leads the ratio 𝑡⁄𝛽 = 0.8 with the Table-4 when the true lifetime of the product is greater

0 𝛽

c=1. From the Table-1theminimum number of groups for the than the specified mean lifetime 𝛽 ≥ β0 𝑜𝑟 β can be

0

consumer’s risk 0.01 is obtained. obtained.

IJISRT22APR238 www.ijisrt.com 1002

Volume 7, Issue 4, April – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

β/β0 1 1.5 2 2.5 3 3.5 4 4.5

L(p) 0.1847 0.3435 0.7221 0.8493 0.9165 0.9522 0.9717 0.9826

Table 4: OC values of (n= 2*6 = 12, c= 1and 𝒕⁄𝜷 = 0.8)under GEP for p*=0.99

𝟎

The minimum mean ratio for this proposed plan efficient plan for studying the percentile life as a quality

referred from the Table-3 is 5.3226 reveals that the product parameter over the other sampling plans. Here the quality

will have an average life of 5 times of the specified average engineer can adopt the proposed sampling plan in the

life of 1000 hours with acceptable probability 0.99. manufacturing sector to reach a decision regarding either to

accept or not to accept the incoming / outgoing quality lots.

IX. CONCLUSIONS To ensure the life quality of the products the pattern of

failure can be occurred using the sampling distribution

This article provides a new statistical probability which protects both the producer and the consumer with

distribution named as Generalized Exponential-Poisson more precision than the specified average life. Suitable

distribution to test the quality of products when acceptance illustrations under electronic toy manufacturing are given

sampling for life test is studied. Numerical table are for ready made reference for the industrial shop floor

developed to obtain the minimum sample size, OC values conditions which provides better discrimination of accepting

and the minimum ratio values are given when producer’s good lots among minimum number of groups.

risk is fixed. The proposed plan was found to be a more

p* c r 𝑡⁄

𝛽0

0.5 0.6 0.7 0.8 0.9 1

0.75 0 2 2 2 1 1 1 1

0.75 1 2 3 3 2 2 2 1

0.75 2 2 5 4 4 3 3 2

0.75 3 2 6 6 5 4 4 3

0.75 4 2 8 7 5 5 5 4

0.90 0 2 3 3 2 2 2 1

0.90 1 2 4 4 3 3 3 2

0.90 2 2 6 5 4 4 4 3

0.90 3 2 8 6 5 5 4 4

0.90 4 2 9 8 7 6 5 5

0.95 0 2 3 3 2 2 2 2

0.95 1 2 5 4 4 3 3 3

0.95 2 2 7 6 5 4 4 4

0.95 3 2 9 7 6 6 5 5

0.95 4 2 11 9 8 7 6 6

0.99 0 2 5 4 3 3 2 2

0.99 1 2 7 6 5 4 4 4

0.99 2 2 9 8 6 6 6 5

0.99 3 2 11 9 8 7 7 6

0.99 4 2 13 11 9 8 7 7

Table 1: minimum number of groups (g) for mean life under GEP Distribution for GASP

IJISRT22APR238 www.ijisrt.com 1003

Volume 7, Issue 4, April – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

𝛽

⁄𝛽

𝑡⁄ 0

p* 𝛽0 g 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5

0.75 0.5 5 0.6878 0.896 0.9619 0.9844 0.9929 0.9965 0.9982 0.999

0.75 0.6 4 0.7275 0.8424 0.9649 0.9852 0.9931 0.9965 0.9981 0.9989

0.75 0.7 4 0.6273 0.7672 0.9396 0.9729 0.9868 0.9931 0.9962 0.9978

0.75 0.8 3 0.7882 0.8749 0.9696 0.9865 0.9935 0.9966 0.9981 0.9989

0.75 0.9 3 0.7308 0.8329 0.9550 0.9791 0.9895 0.9944 0.9968 0.9981

0.75 1 2 * * * * * * *

0.9 0.5 6 0.5507 0.8298 0.9335 0.9717 0.9868 0.9934 0.9965 0.998

0.9 0.6 5 0.5513 0.7154 0.9265 0.9675 0.9844 0.992 0.9956 0.9975

0.9 0.7 4 0.6273 0.7672 0.9396 0.9729 0.9868 0.9931 0.9962 0.9978

0.9 0.8 4 0.5316 0.6873 0.9071 0.9558 0.9775 0.9879 0.9931 0.9959

0.9 0.9 4 0.4446 0.6077 0.8682 0.9337 0.965 0.9805 0.9887 0.9931

0.9 1 3 0.6734 0.7882 0.9374 0.9697 0.9843 0.9914 0.995 0.997

0.95 0.5 7 0.4266 0.7554 0.8981 0.9549 0.9786 0.9891 0.9941 0.9966

0.95 0.6 6 0.3965 0.5844 0.8766 0.9427 0.9717 0.9851 0.9918 0.9952

0.95 0.7 5 0.4277 0.6051 0.878 0.9423 0.9709 0.9844 0.9912 0.9948

0.95 0.8 4 0.5316 0.6873 0.9071 0.9558 0.9775 0.9879 0.9931 0.9959

0.95 0.9 4 0.4446 0.6077 0.8682 0.9337 0.965 0.9805 0.9887 0.9931

0.95 1 4 0.3684 0.5316 0.8243 0.9071 0.949 0.9708 0.9826 0.9892

0.99 0.5 9 0.2376 0.5994 0.8115 0.9104 0.9554 0.9765 0.987 0.9925

0.99 0.6 8 0.1835 0.3571 0.7540 0.8749 0.9344 0.9642 0.9795 0.9879

0.99 0.7 6 0.2743 0.4548 0.8043 0.9015 0.9484 0.9717 0.9838 0.9903

0.99 0.8 6 0.1847 0.3435 0.7221 0.8493 0.9165 0.9522 0.9717 0.9826

0.99 0.9 6 0.1221 0.2539 0.6359 0.7885 0.8766 0.9265 0.9554 0.9717

0.99 1 5 0.1784 0.3242 0.6878 0.821 0.8969 0.9386 0.9625 0.9761

Table 2: OC values for mean life under GEP distribution when c = 2 and r=2 for GASP

p* c 0.5 0.6 0.7 0.8 0.9 1

0.75 0 9.4413 9.6929 9.0878 10.318 11.678 12.936

0.75 1 3.8297 4.0666 4.0701 4.6574 5.248 4.6967

0.75 2 3.1326 3.2184 3.4026 3.4534 3.3427 2.356

0.75 3 2.5081 2.8247 3.0599 2.9279 2.9306 2.7986

0.75 4 2.2781 2.4534 2.3022 2.6307 2.6887 2.6636

0.90 0 11.743 12.738 13.169 15.136 16.944 12.946

0.90 1 4.5896 5.0762 5.3648 5.4389 6.124 5.8175

0.90 2 3.5241 3.7584 3.7553 3.891 4.3589 4.3077

0.90 3 2.9306 3.0048 3.059 3.228 3.2957 3.6514

0.90 4 2.5983 2.7364 3.0256 2.8573 2.9604 2.9891

0.95 0 11.73 12.813 13.259 12.852 17.039 16.226

0.95 1 4.9347 5.4847 5.9173 6.1259 6.1173 6.8047

0.95 2 3.8861 4.0066 4.3795 4.2895 4.3758 4.8652

0.95 3 3.3158 3.3596 3.5127 3.7602 3.9303 4.0357

0.95 4 2.8943 2.9972 3.1883 3.2664 3.4422 3.5721

0.99 0 14.517 16.415 16.457 17.055 17.037 18.834

0.99 1 6.3684 6.6767 6.9081 7.334 7.5843 8.4529

0.99 2 4.5596 5.0792 4.9443 5.3236 6.0006 5.8261

0.99 3 3.7727 3.9763 4.105 4.245 4.7809 4.7092

Table 3: Minimum mean ratio values for the producer’s risk 0.05 under GEP distribution for GASP

IJISRT22APR238 www.ijisrt.com 1004

Volume 7, Issue 4, April – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

REFERENCES

[1.] Aslam, M., Jun, C. H., & Ahmad, M. (2009), A group

sampling plan based on truncated life test for gamma

distributed items. Pak. J. Statist, 25(3), 333-340.

[2.] Aslam, M., & Jun, C. H. (2009). A group acceptance

sampling plan for truncated life test having Weibull

distribution. Journal of Applied Statistics, 36(9), 1021-

1027

[3.] Barreto-Souza, W., &Cribari-Neto, F. (2009). A

generalization of the exponential-Poisson

distribution. Statistics & Probability Letters, 79(24),

2493-2500.

[4.] Epstein, B. (1954): Truncated life tests in the

exponential case. Annals of Mathematical

[5.] Statistics, 25, 555-564.

[6.] Francisco Cribari-Neto (2009) A Generalized

Exponential-Poisson (GEP) Distribution, Statistics and

Probability letters, Vol.79 (24), 1-14.

[7.] Goode, H.P. and Kao, J.H.K. Sampling Plans Based on

the WeibullDistribution. Proceedings of Seventh

National Symposium on Reliability and Quality

Control, Philadelphia, 24-40, 1961.

[8.] Jun, C.H., Balamuarli, S. and Lee, S.H (2006),

Variable sampling plans for Weibull distribution

lifetimes under sudden death testing, IEEE Transaction

on Reliability 55, 53-58.

[9.] Kaviyarasu, V., & Suresh, K. K. (2011). Certain

Results and Tables Relating to QSS-1 with Multiple

RGS Plan as Reference Plan. Journal of Mathematics

Research, 3(4), 158.

[10.] Kaviyarasu, V. and Fawaz, P. (2017), A reliability

sampling plan to ensure percentiles through Weibull

Poisson distributions, International Journal of Pure and

Applied Mathematics, Vol.117(13), 155-163.

[11.] Kaviyarasu, V. and Sivasankari, S. (2020), Acceptance

sampling for life testing under Generalized

Exponential-Poisson Distribution, International Journal

of Mathematics trends and Technology, Vol.66 (12),

148-156.

[12.] Kuş, C. (2007). A new lifetime

distribution. Computational Statistics & Data

Analysis, 51(9), 4497-4509.

[13.] Muhammad Aslam, Muhammad Khalid Pervaiz, Chi-

Hyuck Jun(2010), “AnImproved Group Sampling Plan

Based on Time-Truncated Life Tests”, Communication

of the Korean Statistical Society,2010, Vol 17, No.3,

319-326.

[14.] Rao, G. S. (2009). A group acceptance sampling plans

based on truncated life tests for Marshall-Olkin

extended Lomax distribution. Electronic Journal of

Applied Statistical Analysis, 3(1), 18-27.

[15.] Rosaiah, K., Rao, G. S., & Prasad, S. V. S. V. S. V.

(2016). A group acceptance sampling plans based on

truncated life tests for Type-II generalized log-logistic

distribution. In Prob Stat Forum, Vol. 9, pp. 88-94.

[16.] Sudamani Ramaswamy A.R &Sutharani S(2012),

“Designing Weighted Group Sampling Plan Based on

Truncated Life Tests under various Distribution using

Minimum Angle Method”, International J of

Math.Sci&Engg. Appls. (IJMSEA) Vol.8 (11) 171-

185.

IJISRT22APR238 www.ijisrt.com 1005

You might also like

- 4190 FullTextArticle 16844 1 10 20221206Document20 pages4190 FullTextArticle 16844 1 10 20221206vidyayNo ratings yet

- Ajams 6 5 2Document5 pagesAjams 6 5 2Krzyszto FPNo ratings yet

- Woklf - Bi D R VK ¡Um Umof Dog Rolb JD) W D I Wi DDocument17 pagesWoklf - Bi D R VK ¡Um Umof Dog Rolb JD) W D I Wi Delyes elyesNo ratings yet

- Analyzing Test Case Selection & Prioritization Using ACO: ACM SIGSOFT Software Engineering Notes September 2011Document6 pagesAnalyzing Test Case Selection & Prioritization Using ACO: ACM SIGSOFT Software Engineering Notes September 2011Preet SinghNo ratings yet

- Research DesignDocument46 pagesResearch DesignLemony Snickett100% (1)

- SGI Test Offprint (Amelunxen Et Al)Document11 pagesSGI Test Offprint (Amelunxen Et Al)cesar_a_gonzalez_lNo ratings yet

- Amelunxen2014 PDFDocument10 pagesAmelunxen2014 PDFDiegoAlvarezHuguezNo ratings yet

- PH.D Thesis M. UshaDocument185 pagesPH.D Thesis M. UshaAdrian Serban100% (1)

- Design and Analysis of Efficacy Evaluation Trials: Specific Scope Specific Approval and AmendmentDocument15 pagesDesign and Analysis of Efficacy Evaluation Trials: Specific Scope Specific Approval and AmendmentIgor CañapatañaNo ratings yet

- DSAASTAT - by Andrea OnofriDocument10 pagesDSAASTAT - by Andrea OnofridunnavijayNo ratings yet

- Cristea 2018 IOP Conf. Ser. Mater. Sci. Eng. 444 072007Document8 pagesCristea 2018 IOP Conf. Ser. Mater. Sci. Eng. 444 072007Jay PanchalNo ratings yet

- Wang 2014Document22 pagesWang 2014Jesico IdNo ratings yet

- The Taguchi Methodology As A Statistical PDFDocument14 pagesThe Taguchi Methodology As A Statistical PDFana bawukeNo ratings yet

- Research DesignDocument84 pagesResearch DesignOm PrakashNo ratings yet

- Statistics As A Catalyst To Learning by Scientific Method Part I-An ExampleDocument15 pagesStatistics As A Catalyst To Learning by Scientific Method Part I-An ExampleBhishm DewanganNo ratings yet

- Ipqc PDFDocument11 pagesIpqc PDFAshraf Farhoud100% (2)

- Pilot Study MethodologyDocument5 pagesPilot Study MethodologyThierry UhawenimanaNo ratings yet

- Stability Shelf Life Working Group: Presented by Michelle Quinlan On Behalf of The Working GroupDocument36 pagesStability Shelf Life Working Group: Presented by Michelle Quinlan On Behalf of The Working GroupIbad MuhammedNo ratings yet

- Appendix D - Guidelines For Collaborative Study Procedures To Validate Characteristics of A Method of AnalysisDocument12 pagesAppendix D - Guidelines For Collaborative Study Procedures To Validate Characteristics of A Method of AnalysisFer RodriguezNo ratings yet

- 2011 Enciclopedia-Mine ASG PDFDocument5 pages2011 Enciclopedia-Mine ASG PDFAhmed OmarNo ratings yet

- A New Concept for Tuning Design Weights in Survey Sampling: Jackknifing in Theory and PracticeFrom EverandA New Concept for Tuning Design Weights in Survey Sampling: Jackknifing in Theory and PracticeNo ratings yet

- Adherence To Key Recommendations For Design and Analysis of Stepped-Wedge Cluster Randomized Trials - A Review of Trials Published 2016-2022Document12 pagesAdherence To Key Recommendations For Design and Analysis of Stepped-Wedge Cluster Randomized Trials - A Review of Trials Published 2016-2022charmyshkuNo ratings yet

- AOAC Appendeix D 2023Document26 pagesAOAC Appendeix D 2023Nana BiotayudaNo ratings yet

- TEXTO 10 - IFRGguidelinesIAI2014Document28 pagesTEXTO 10 - IFRGguidelinesIAI2014Cintia GrazielaNo ratings yet

- 07 - Production Planning and Scheduling of Parallel Continuous ProcessesDocument10 pages07 - Production Planning and Scheduling of Parallel Continuous ProcessesAzat SuleimenovNo ratings yet

- ilkay - saracoglu - paper جدول تصنيف PDFDocument15 pagesilkay - saracoglu - paper جدول تصنيف PDFď èNo ratings yet

- Design Experiments For MQL1Document15 pagesDesign Experiments For MQL1VishalDabhadeNo ratings yet

- GCE Biology Unit 6 TSM Final (Unit 6 Guide and Examples From Edexcel)Document76 pagesGCE Biology Unit 6 TSM Final (Unit 6 Guide and Examples From Edexcel)razoraz90% (10)

- Review of Experimental Design in Analytical ChemistryDocument16 pagesReview of Experimental Design in Analytical ChemistrybetelgueseNo ratings yet

- An Updated Review On IPQC Tests For Sterile and Non Sterile ProductsDocument12 pagesAn Updated Review On IPQC Tests For Sterile and Non Sterile ProductsJvnNo ratings yet

- 299 587 1 SMDocument7 pages299 587 1 SMAldi FebrianNo ratings yet

- Evaluating Time Series Forecasting Models: An Empirical Study On Performance Estimation MethodsDocument28 pagesEvaluating Time Series Forecasting Models: An Empirical Study On Performance Estimation MethodsmarvinNo ratings yet

- Experimental Planning Factorial A Brief ReviewDocument13 pagesExperimental Planning Factorial A Brief ReviewAnar HaciyevNo ratings yet

- Calculation of Measurement Uncertainty: HandbookDocument54 pagesCalculation of Measurement Uncertainty: Handbookghassan72 ghassanNo ratings yet

- Artur Manuel António Gildo Albano Luís TivanaDocument13 pagesArtur Manuel António Gildo Albano Luís TivanaGildo AlbanoNo ratings yet

- In Math and ResearchDocument3 pagesIn Math and Researchʚîɞ Ilasco YvonNo ratings yet

- Reliability & Theory ScopusDocument13 pagesReliability & Theory ScopusShaan Computer Jio BhaiNo ratings yet

- An Updated Review On IPQC Tests For Sterile and Non Sterile ProductsDocument12 pagesAn Updated Review On IPQC Tests For Sterile and Non Sterile ProductsJay RanaNo ratings yet

- BAYREUTHDocument15 pagesBAYREUTHAjitNo ratings yet

- Pag Activity Biology Testing For Biological Molecules Suggestion 1Document20 pagesPag Activity Biology Testing For Biological Molecules Suggestion 1ً SEONPREMACYNo ratings yet

- 1 s2.0 S0165178119306833 MainDocument7 pages1 s2.0 S0165178119306833 MainHindi ako goodsNo ratings yet

- Group 7 Experimental Research Design - 072543Document14 pagesGroup 7 Experimental Research Design - 072543Rengga GustiNo ratings yet

- Research Methods in Psychology 10Th Edition Shaughnessy Solutions Manual Full Chapter PDFDocument52 pagesResearch Methods in Psychology 10Th Edition Shaughnessy Solutions Manual Full Chapter PDFJeffreyWalkerfpqrm100% (9)

- Research Methods in Psychology 10th Edition Shaughnessy Solutions ManualDocument31 pagesResearch Methods in Psychology 10th Edition Shaughnessy Solutions Manualfarleykhucucc59v100% (28)

- Repeated Measure DesignDocument8 pagesRepeated Measure Designstudent0990No ratings yet

- Demand Forecasting and Inventory Control A Simulation Study On Automotive Spare Parts PDFDocument16 pagesDemand Forecasting and Inventory Control A Simulation Study On Automotive Spare Parts PDFRais HaqNo ratings yet

- A Comparison of Test Case Prioritization Criteria For Software Product LinesDocument11 pagesA Comparison of Test Case Prioritization Criteria For Software Product LinestomboNo ratings yet

- The Block Planning Approach For Continuous Time Based Dynamic Lot Sizing and SchedulingDocument26 pagesThe Block Planning Approach For Continuous Time Based Dynamic Lot Sizing and SchedulingFernando DlpNo ratings yet

- BIBDDocument109 pagesBIBDShikha Kashyap100% (1)

- Chapter One 1.1 Background of The Study The Experimental Design Is The Design of Any Task That Aims To Describe orDocument7 pagesChapter One 1.1 Background of The Study The Experimental Design Is The Design of Any Task That Aims To Describe orOmotayo AbayomiNo ratings yet

- Assessment of Blend and Content UniformityDocument14 pagesAssessment of Blend and Content Uniformityshah777100% (1)

- Rev LogDocument18 pagesRev LogSHRAYANSH AGARWALNo ratings yet

- Chapter 9Document11 pagesChapter 9Embassy and NGO jobsNo ratings yet

- Food Quality and Preference: C. Peltier, P.B. Brockhoff, M. Visalli, P. SchlichDocument4 pagesFood Quality and Preference: C. Peltier, P.B. Brockhoff, M. Visalli, P. SchlichVisal SasidharanNo ratings yet

- Moussaoui 2010Document12 pagesMoussaoui 2010OLENKANo ratings yet

- Research II Q1 M5Document15 pagesResearch II Q1 M5eikomedleyNo ratings yet

- A Protocol For The Validation of Qualitative Methods of AnalysisDocument27 pagesA Protocol For The Validation of Qualitative Methods of Analysisanim45No ratings yet

- Study Guide for Practical Statistics for EducatorsFrom EverandStudy Guide for Practical Statistics for EducatorsRating: 4 out of 5 stars4/5 (1)

- Applications of Hypothesis Testing for Environmental ScienceFrom EverandApplications of Hypothesis Testing for Environmental ScienceNo ratings yet

- Designing Cost-Effective SMS based Irrigation System using GSM ModuleDocument8 pagesDesigning Cost-Effective SMS based Irrigation System using GSM ModuleInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Effect of Solid Waste Management on Socio-Economic Development of Urban Area: A Case of Kicukiro DistrictDocument13 pagesEffect of Solid Waste Management on Socio-Economic Development of Urban Area: A Case of Kicukiro DistrictInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Utilization of Waste Heat Emitted by the KilnDocument2 pagesUtilization of Waste Heat Emitted by the KilnInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Impact of Stress and Emotional Reactions due to the Covid-19 Pandemic in IndiaDocument6 pagesImpact of Stress and Emotional Reactions due to the Covid-19 Pandemic in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- An Overview of Lung CancerDocument6 pagesAn Overview of Lung CancerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Digital Finance-Fintech and it’s Impact on Financial Inclusion in IndiaDocument10 pagesDigital Finance-Fintech and it’s Impact on Financial Inclusion in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Auto Tix: Automated Bus Ticket SolutionDocument5 pagesAuto Tix: Automated Bus Ticket SolutionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Predictive Analytics for Motorcycle Theft Detection and RecoveryDocument5 pagesPredictive Analytics for Motorcycle Theft Detection and RecoveryInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Computer Vision Gestures Recognition System Using Centralized Cloud ServerDocument9 pagesComputer Vision Gestures Recognition System Using Centralized Cloud ServerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Ambulance Booking SystemDocument7 pagesAmbulance Booking SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Cyber Security Awareness and Educational Outcomes of Grade 4 LearnersDocument33 pagesCyber Security Awareness and Educational Outcomes of Grade 4 LearnersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Parastomal Hernia: A Case Report, Repaired by Modified Laparascopic Sugarbaker TechniqueDocument2 pagesParastomal Hernia: A Case Report, Repaired by Modified Laparascopic Sugarbaker TechniqueInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- An Industry That Capitalizes Off of Women's Insecurities?Document8 pagesAn Industry That Capitalizes Off of Women's Insecurities?International Journal of Innovative Science and Research TechnologyNo ratings yet

- Unmasking Phishing Threats Through Cutting-Edge Machine LearningDocument8 pagesUnmasking Phishing Threats Through Cutting-Edge Machine LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Factors Influencing The Use of Improved Maize Seed and Participation in The Seed Demonstration Program by Smallholder Farmers in Kwali Area Council Abuja, NigeriaDocument6 pagesFactors Influencing The Use of Improved Maize Seed and Participation in The Seed Demonstration Program by Smallholder Farmers in Kwali Area Council Abuja, NigeriaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Study Assessing Viability of Installing 20kw Solar Power For The Electrical & Electronic Engineering Department Rufus Giwa Polytechnic OwoDocument6 pagesStudy Assessing Viability of Installing 20kw Solar Power For The Electrical & Electronic Engineering Department Rufus Giwa Polytechnic OwoInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Forensic Advantages and Disadvantages of Raman Spectroscopy Methods in Various Banknotes Analysis and The Observed Discordant ResultsDocument12 pagesForensic Advantages and Disadvantages of Raman Spectroscopy Methods in Various Banknotes Analysis and The Observed Discordant ResultsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Smart Health Care SystemDocument8 pagesSmart Health Care SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Blockchain Based Decentralized ApplicationDocument7 pagesBlockchain Based Decentralized ApplicationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Smart Cities: Boosting Economic Growth Through Innovation and EfficiencyDocument19 pagesSmart Cities: Boosting Economic Growth Through Innovation and EfficiencyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Impact of Silver Nanoparticles Infused in Blood in A Stenosed Artery Under The Effect of Magnetic Field Imp. of Silver Nano. Inf. in Blood in A Sten. Art. Under The Eff. of Mag. FieldDocument6 pagesImpact of Silver Nanoparticles Infused in Blood in A Stenosed Artery Under The Effect of Magnetic Field Imp. of Silver Nano. Inf. in Blood in A Sten. Art. Under The Eff. of Mag. FieldInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Visual Water: An Integration of App and Web To Understand Chemical ElementsDocument5 pagesVisual Water: An Integration of App and Web To Understand Chemical ElementsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Insights Into Nipah Virus: A Review of Epidemiology, Pathogenesis, and Therapeutic AdvancesDocument8 pagesInsights Into Nipah Virus: A Review of Epidemiology, Pathogenesis, and Therapeutic AdvancesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Compact and Wearable Ventilator System For Enhanced Patient CareDocument4 pagesCompact and Wearable Ventilator System For Enhanced Patient CareInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Air Quality Index Prediction Using Bi-LSTMDocument8 pagesAir Quality Index Prediction Using Bi-LSTMInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Predict The Heart Attack Possibilities Using Machine LearningDocument2 pagesPredict The Heart Attack Possibilities Using Machine LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- An Analysis On Mental Health Issues Among IndividualsDocument6 pagesAn Analysis On Mental Health Issues Among IndividualsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Parkinson's Detection Using Voice Features and Spiral DrawingsDocument5 pagesParkinson's Detection Using Voice Features and Spiral DrawingsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Quantifying of Radioactive Elements in Soil, Water and Plant Samples Using Laser Induced Breakdown Spectroscopy (LIBS) TechniqueDocument6 pagesQuantifying of Radioactive Elements in Soil, Water and Plant Samples Using Laser Induced Breakdown Spectroscopy (LIBS) TechniqueInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Implications of Adnexal Invasions in Primary Extramammary Paget's Disease: A Systematic ReviewDocument6 pagesImplications of Adnexal Invasions in Primary Extramammary Paget's Disease: A Systematic ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Jicable19-19 Treeing Asset Management FinalDocument6 pagesJicable19-19 Treeing Asset Management FinalLucho RufoNo ratings yet

- Faizal Rahman Dr. Samsir, SE.,M.Si Iwan Nauli Daulay, ST.,MMDocument8 pagesFaizal Rahman Dr. Samsir, SE.,M.Si Iwan Nauli Daulay, ST.,MMZulfi AkhmadNo ratings yet

- Chapter (3) Three (B)Document65 pagesChapter (3) Three (B)Hussen MohammedNo ratings yet

- 5 Diagnostics As Basis For Condition Based MaintenanceDocument16 pages5 Diagnostics As Basis For Condition Based Maintenanceured cizminNo ratings yet

- XB320 BrochureDocument6 pagesXB320 Brochurehiren maruNo ratings yet

- Parle GDocument27 pagesParle GSoham Naik50% (2)

- AMCO - James QuillickDocument8 pagesAMCO - James QuillickOwais MalikNo ratings yet

- 18F46-DOMI of Pumps Level 2Document2 pages18F46-DOMI of Pumps Level 2ehabwardaNo ratings yet

- Maintenance Excellence MatrixDocument214 pagesMaintenance Excellence MatrixRadivojJovanov100% (1)

- Master Arbeit KUNZ 150104Document317 pagesMaster Arbeit KUNZ 150104alibaba1888No ratings yet

- ME2037 Maintenance EngineeringDocument46 pagesME2037 Maintenance Engineeringrp0212100% (2)

- Paper - Assessment of The Loadbearing Capacity of Historic MasonryDocument10 pagesPaper - Assessment of The Loadbearing Capacity of Historic Masonryraziul.aliNo ratings yet

- Cable TVDocument41 pagesCable TVShyju Sukumaran83% (6)

- Haul Truck Payload Modelling Using Strut PressuresDocument119 pagesHaul Truck Payload Modelling Using Strut PressurestehnoNo ratings yet

- Tech. Corp.: SpecificationsDocument28 pagesTech. Corp.: SpecificationsRDS COMUNICACIONES E.I.R.LNo ratings yet

- FTA Metodology Cam0500244 enDocument14 pagesFTA Metodology Cam0500244 enstefanNo ratings yet

- Ieee Gold Book Standard 493 2007Document3 pagesIeee Gold Book Standard 493 2007Patricia0% (2)

- OpenDSS Bus Interface PDFDocument4 pagesOpenDSS Bus Interface PDFLucas GodoiNo ratings yet

- Jermaine's ResumeDocument1 pageJermaine's Resumeshereese25No ratings yet

- VR 2019 Ba BaaDocument152 pagesVR 2019 Ba BaaAndrei MacarescuNo ratings yet

- Boilers Tube Failure Analysis 2018 Rev 0Document74 pagesBoilers Tube Failure Analysis 2018 Rev 0Zia AbbasiNo ratings yet

- PROCEQ Equotip-550 PDFDocument14 pagesPROCEQ Equotip-550 PDFSiti NurhikmahNo ratings yet

- CIGREDocument6 pagesCIGREGastón MassaferroNo ratings yet

- Product DesignDocument18 pagesProduct DesignPangitkaNo ratings yet

- AMP Check ListDocument8 pagesAMP Check ListCAM TAVNo ratings yet

- Proof Testing of Safety Instrumented Systems in The Onshore ChemicalDocument13 pagesProof Testing of Safety Instrumented Systems in The Onshore ChemicalmuathudongNo ratings yet

- Cmu Cs 447 Dis Techtips Proposal 1Document7 pagesCmu Cs 447 Dis Techtips Proposal 1Xuân ĐiềnNo ratings yet

- Enhanced Steam Reformer Tube Inspection and Remaining Life Assessment ApproachDocument4 pagesEnhanced Steam Reformer Tube Inspection and Remaining Life Assessment ApproachRabah BrikaNo ratings yet

- UPD70F3425-Renesas Electronics PDFDocument1,050 pagesUPD70F3425-Renesas Electronics PDFsergioradNo ratings yet

- Permanent Monitoring - Looking at Lifetime Reservoir DynamicsDocument15 pagesPermanent Monitoring - Looking at Lifetime Reservoir Dynamicsnoorul786No ratings yet