This article is part of the

SPRING 2023 R&D NEWSLETTER

In This Issue

For a week and a half in 2022, Jake Gentle and members of the U.S. military loaded a new kind of wind turbine onto an armored vehicle and drove it over rock ledges, down gravel roads, and through sagebrush.

“What we really wanted to do is prove its ruggedness,” said Gentle, a senior power systems engineer for the U.S. Department of Energy’s Idaho National Laboratory (INL). “In a natural disaster situation, you can’t show up with a cardboard box. It’s got to be rugged.”

That ruggedness test—assembly, disassembly, and operationality in multiple environments such as dirt and gravel roads, lava rocks, and ledges—was part of the 4-year-long Defense and Disaster Deployable Turbine project, also known as D3T, which concluded in Fall 2022. Funded by the U.S. Department of Energy’s Wind Energy Technologies Office, D3T brought together experts from INL, the National Renewable Energy Laboratory (NREL), and Sandia National Laboratories to analyze how to build a wind turbine that could serve both military and humanitarian missions around the world.

Hurricanes, earthquakes, and armed conflict can wreak havoc anywhere, including remote islands or near-empty deserts where electricity can be scarce, expensive, or both. And when military or aid organizations race to help communities rebuild, they need a reliable source of energy that anyone can set up and run as quickly as possible.

Some missions use portable solar panels or diesel generators to power their work. But not all disaster zones get enough sun for operations to depend on solar panels alone. Diesel generators might be easy to run, but they need steady shipments of liquid fuel. If the mission lasts months or even years, those shipments come with high emissions, costs, and risks—and if the terrain proves too rocky or rugged, some might not arrive at all. But wind energy, the D3T team found, could be a reliable source of power for many of these missions, especially as part of a microgrid alongside solar panels, energy storage systems, and even diesel generators.

Additionally, power generated from deployable wind turbines offsets diesel fuel needed in conflict zones. Deployable wind turbines can reduce both the amount of diesel needed and the number of troops put at risk in slow-moving supply convoys, keeping military personnel focused on the larger mission.

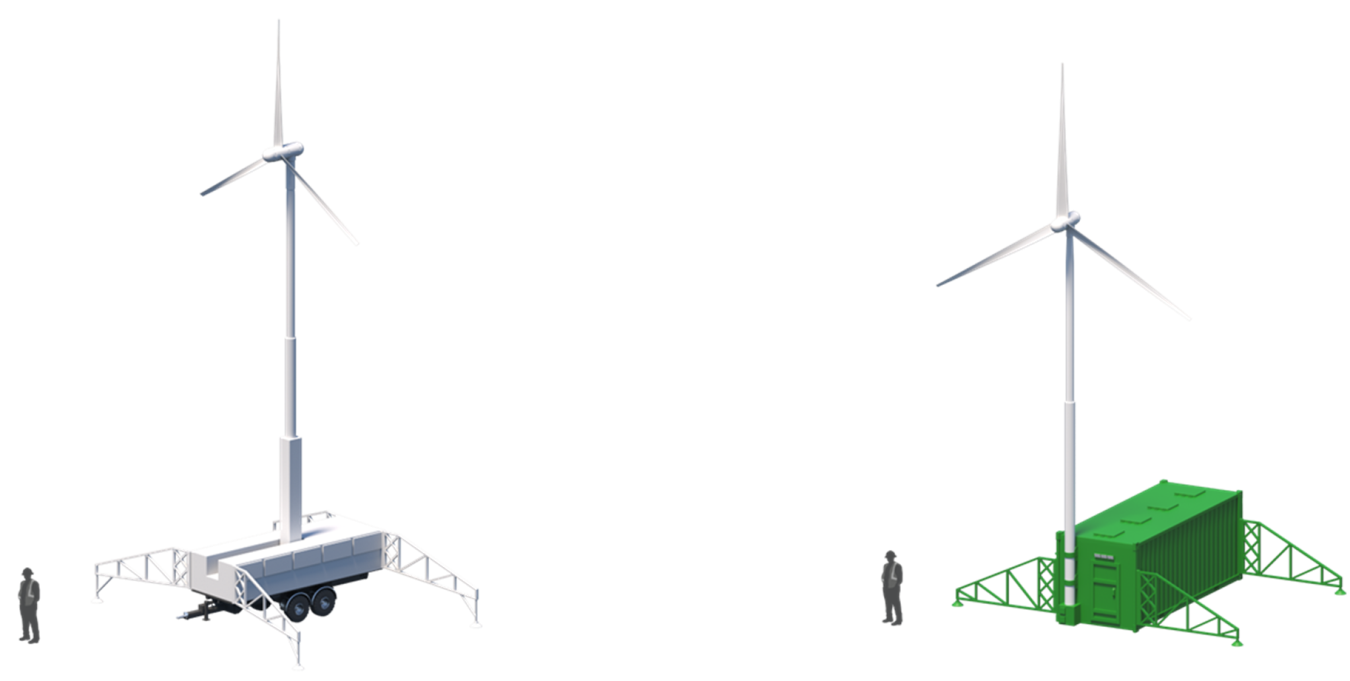

But unlike solar panels, traditional wind turbines are not easy to transport and install. Most require cement, heavy towers, and large cranes to erect. So, the D3T team worked to define new design parameters for a wind turbine that could be broken down to fit in a standard military shipping container and be easily erected.

For even faster setup, deployable wind turbines could use their shipping containers as a foundation.

“All these missions care about is if they have a 10-megawatt power system, it will turn on and produce 10 megawatts of power,” said Gentle. “When I want it on, it’s on.”

At INL, Gentle and Dylan Reen, the lab’s D3T lead investigator, worked with members of military and humanitarian organizations to determine what kind of energy system they might need—evaluating, for example, what voltage and current might serve them best, how they might plug their turbine in to connect it to where power is needed, and what materials would best survive in often inhospitable disaster areas. “Even if the windstorm or rainstorm comes back,” Gentle said, “I don’t have to worry about the system not turning on.”

Brent Summerville, a distributed wind energy systems engineer and NREL’s lead D3T investigator, led the effort to make sure their wind turbine could get wherever it needed to go. “It needs to be portable, assemble quickly, and get to work,” said Summerville. “That’s a whole different challenge than the wind energy industry was used to. It doesn't necessarily need to be the cheapest cost of energy. But it does need to be easily deployed, easy to operate, and reliable.”

Because both the military and the American Red Cross prefer 20-foot shipping containers, Summerville and his team found that this standard size could fit a 20-kilowatt turbine, modified to assemble and disassemble quickly. As a bonus, there’d be room for solar panels and batteries, though further research is needed to determine how many extra kilowatts worth of equipment might fit in the container. The shipping container could also serve as a base for this portable microgrid, making it even easier for the end user to get the system up-and-running as fast as possible.

As a final step, the D3T project team hosted a virtual workshop in June 2022. There, wind turbine developers and suppliers met with their potential customers: military and disaster response organizations. Both customers reported similar needs, including simple yet tough technologies that are easy to operate and can pair with other energy sources.

“We know wind turbines alone won’t be the solution,” Gentle said. “We need wind, solar, storage and other sources of energy to work together in a secure and reliable way.”

Read about the Defense and Disaster Deployable Turbine project.

Spring 2023 R&D Newsletter

Subscribe to the WETO e-newsletter to stay informed on the latest wind energy news, events, publications, and updates.